Linija pirkti naudotą (2 774)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Mažas skelbimas

Strenči

Strenči

295 km

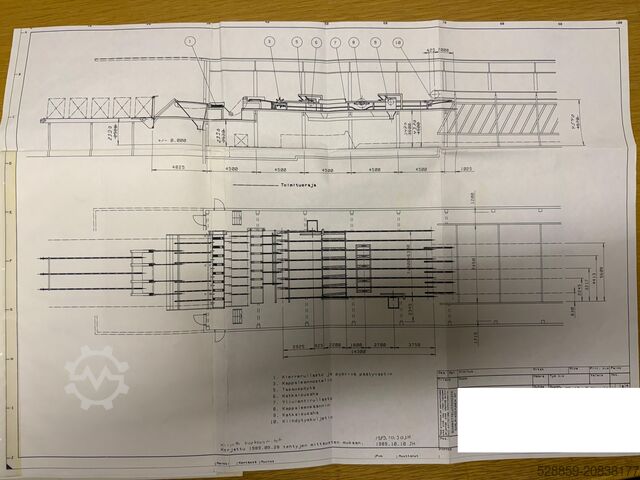

Lentos rūšiavimo linija

Skambinti

Sąlyga: naudotas, Lentų rūšiavimo linija

Gamintojas: Lekopa

Pjdpfxjx N S Hbo Af Njgg

Pagaminimo metai: 1989

16 kišenių

Pakavimo presas

Dėklas su tarpikliais

Dynagrade

Mažas skelbimas

Mierzęcice

Mierzęcice

613 km

Lakštinio metalo pjaustymo linija lapams/formatams

Sestal

Skambinti

Sąlyga: naujas, Funkcionalumas: visiškai funkcionalus, Gamybos metai: 2026, valdymo tipas: PLC valdomas, automatizacijos lygis: automatinis, pavaros tipas: elektrinis, Paprasta išilginio ir skersinio pjovimo staklės, skirtos lakštams, kurių storis nuo 0,40 iki 0,80 mm ir plotis iki 1250 mm.

Specifikacija:

- Įrenginys su 6 poromis peilių, gali išpjauti iki 7 juostų, minimalus juostos plotis – 60 mm (rankinis reguliavimas). Pjovimo ilgio tolerancija ≤± 2,0 mm. Automatinė kiekio ir ilgio kontrolė.

Pgsdpfxsx U Exhe Af Nsg

- Pjovimo peilių medžiaga: Cr12, tiksli mechaninė apdirbimas, termiškai apdorota.

- Galia: 4 kW. Elektros standartas: 380 V/50 Hz/3 fazės

- Valdymo įtampa: 24 V

- Komplektacijoje: PLC (Siemens), liečiamas ekranas (Siemens), dažnio keitiklis (Schneider), enkoderis (Omron) ir kt.

- Galimybė komplektuoti su mechaniniu arba automatiniu atraižų atraižų nuvyniotuvu

Mažas skelbimas

Åsby

Åsby

682 km

Rąstų rūšiavimo linija

Ingvar Persson ABKSAB 4000

Skambinti

Sąlyga: paruoštas naudoti (naudotas),

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

Vokietija

Vokietija

999 km

Gamybos linija

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Skambinti

Sąlyga: naudotas, Number of machines: 9 units.

Wooden window production line for sale on behalf of a customer.

Machines can still be inspected in operation. Sale includes machines, all tools, and programming for the manufactured systems. Suitable for production of angled and arched windows.

Item 1: Weinig Powermat 500, year of manufacture 2010, window version

-----

- 6 spindles, 5 of which with PowerLock

- 8,000 rpm

- Equipped for glazing bead cut-out

- Large PowerCom control system

- Includes existing planing and moulding tools by Leitz

- Linked with Maweg single timber sanding machine Saturn Duo, year 1985, as well as workpiece return conveyor

Item 2: SCM Windor 40 R window system, year 2006

-----

- 2 long slot spindles, CNC controlled

- 3 long profiling spindles, CNC controlled, plus upper and lower units

- Rebate wagon for small sash frames

- ROTATEN: Angled window device

- Including Leitz window and door tooling

- Including separate OKOMA UF 3 rebate machine with tools

Item 3: HOMAG CNC processing center BMG310/42/F/K, year 2018

-----

- Gantry machine, 5-axis Drive 5C+ with 15 kW

- Overhead laser

- Working area: 4200 mm length, 1350 mm depth

- 32-position disc tool changer

- 8-position line changer

- Fixed drilling head: 18 spindles (V12/H6/S0/90 degrees)

- 8 consoles

- 6 lifting rails

- Connection for 8 PowerClamp clamps

- Approx. 30 vacuum clamps

- 4 PowerClamp clamps

- WoodWop

- Chip conveyor

- Various small solid wood clamps (used for box-type windows)

- Including Leitz tooling for Homag, with arched window capability

- Including Barbaric vacuum lifter, year 2015

Item 4: Löwer MZP 1 mini finger joint press

-----

- For arched window production

Item 5: S+S frame press type Bavaria 200 L, year 2014

-----

- Working area: 4000 x 2600 mm

- With center pressure beam and transverse clamping device

- Motorised width adjustment

- Standard counter-profiles

- Angled window control system

- Swing pressure plates + extension for pointed windows

- Intermediate spacer for small lot pressings

- Various support plates for counter-profiles and counter-profiles

Item 6: Striffler sash hardware table

-----

- With automatic screwdriver and screw feed

- Hardware rack

- Punch for Roto fittings

Item 7: Stegherr KF counter-profile milling machine

-----

- With mounted tools

Item 8: Tools

-----

All tools belonging to the machines for the wood and wood-aluminium systems IV 72 + 92 mm shown in the PDF

- Windows

- Lift and slide doors

- Arched and angled windows

- Box windows

- Numerous types of front doors

Pgedpfxeyclwxj Af Nog

- Putty rebate variants

- ...

Sale of the tools as-is, with accessories as currently available. Note on window profiles, tool drawings, tool system listings:

Engelfried GmbH provides no warranty that the tools actually present correspond with the specified or illustrated systems.

(Technical data according to manufacturer, no guarantee!)

-----

Total price for items 1 ...

Mažas skelbimas

Rzeszów

Rzeszów

585 km

Tešlos linija

Seewer RondoRondoline

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2001, 670 USED Seewer Rondo industrial line, model RONDOLINE, LOTS OF EQUIPMENT included in the set:

- calibrator,

- filling module,

Pgsdpfxopl Urts Af Neg

- sugar sprinkling unit, etc.,

- hard toppings sprayer,

- double rolling with rollers,

- guillotine,

- many interchangeable cutting dies,

- a variety of rollers.

The line comes with additional spare parts.

A large assortment of accessories and extras, as shown in the photos.

year of manufacture: 2001

EXTERNAL DIMENSIONS (in cm):

- length: 1430

- width: 130

The machine is located in our warehouse (36-068 Bachórz).

Paid options available: transport.

The listed price is net.

WE SPEAK ENGLISH, GERMAN, FRENCH, RUSSIAN, UKRAINIAN.

Atraskite daugiau naudotų mašinų

Mažas skelbimas

Rzeszów

Rzeszów

585 km

Duonos linija, ciabatta

KönigLIPPELT RUSTICA

Skambinti

Sąlyga: labai geros būklės (naudotas), 622 USED Koenig Lippelt Rustica ciabatta machine.

EXTERNAL DIMENSIONS (in cm):

- width: 180,

- length: 75,

- height: 153.

TECHNICAL DATA:

- 4 cutting rollers.

Pgjdpfxjnpxl Do Af Neg

The machine is available for inspection at our warehouse (36-068 Bachórz, Poland).

Paid options available: transport.

The indicated price is net.

WE SPEAK ENGLISH, GERMAN, FRENCH, RUSSIAN, AND UKRAINIAN.

Mažas skelbimas

Menslage

Menslage

1 081 km

Siapi, Melegari, PE Comag, TMG, Domino, Atlanta PET (vienkartinė) išpilstymo linija (2008)

Siapi, Melegari, PEAbfülllinie für PET (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2008, Overview

This complete PET water bottling line was predominantly manufactured in 2006 by renowned European manufacturers such as Siapi, Melegari S.p.A, P.E Srl, K, Comag, TMG, Domino, and Atlanta. The line will remain in production until the end of June 2025, providing the opportunity to see it running live. All equipment is in very good working condition with a full maintenance history, making it a turnkey solution ready for immediate operation.

Technical Data

- Capacity: up to 6,800 bph for 0.5L bottles, up to 6,000 bph for 1.5L bottles

- Formats: 500ml PET, 1500ml PET

- Neck finish: 30/25

- Packaging:

- 500ml bottles: packs of 24 in shrink film

- 1.5L bottles: packs of 6 in shrink film

- Bottle diameter: 203mm (0.5L), 317mm (1.5L)

Pgsdpfx Afswz H Aho Njg

- Line condition: very good, complete maintenance history available

Scope of supply

- Blow molder: Siapi EA4 | 2008

- Filling machine: Melegari S.p.A Fill Jet 20/20/4 | 2001

- Labelling machine: P.E Srl 8T.540.1S.1E | 2002

- Shrink tunnel: K Tunnel 70S | 2007

- Shrink wrapper: K Nice Wrap35 SFUSO | 2008

- Carry handle applicator: Comag H 40/1 | 2008

- Palletizer: TMG

- Inkjet printer: Domino A200

- Pallet wrapper: Atlanta Mytho A | 2009

Mažas skelbimas

Menslage

Menslage

1 081 km

Klinger, Krone, Nate ir kiti stiklo butelių užpildymo linija (daugkartinio naudojimo) (2004)

Klinger, Krone, NateAbfülllinie für Glasflaschen (Mehrweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2004, Overview

This complete returnable glass bottle filling line was manufactured between 1993 and 2004 by several renowned European manufacturers, primarily Klann, Klinger, Krones, Nate, and Datz. The line is designed for high-performance beverage production and processes up to 20,000 bottles per hour in various formats. It includes all components from depacker to packer. Despite its age, the line is in good condition. The labelling machine was fully serviced in 2023. The entire system remains installed and connected and can be inspected upon request.

Pgsdpfxjyb R Uas Af Nog

Technical Data

Capacity: up to 20,000 bph

Bottle formats: 0.25 L Vichy, 0.5 L Set 1-3, 0.7 L GDB, 0.75 L GDB

Application: Water, CSD, or other beverages in returnable glass bottles

Condition: Line in good condition

Availability: Immediately

Status: Still installed and connected

Scope of Supply

Depacker | Otto Fleischer | 1993

Crate washer | Klann | 2,000 crates/hour | 1997 | GDB crates, stainless steel

Bottle washer | Klinger | 1993 | Stainless steel, multi-zone, steam exhaust, dosing system

Empty bottle inspector | Krones | up to 50,000 bottles/hour | 2004 | Linatronic system

Filler | Nate-Veral 60 | 20,000 bottles/hour | 2004 | glass bottles, without capper

Capper | Datz | 20,000 bottles/hour | 2004 | 8-head Solo SV, left-right operation

grolsch/swing top capper | Datz | 20,000 bottles/hour | 2004 | 24-head BVM-24R, swing top

Labeller | Krones | up to 20,000 bottles/hour | 2004 | Prontomatic, 2 stations, Checkmat inspection

Packer | Otto Fleischer | 1993 | ROTA 1 E, automatic group packer

Mažas skelbimas

Menslage

Menslage

1 081 km

Krones Heuft-KHS-SIG Coroplast PET (vienkartinio) užpildymo linija (2000 m.)

KronesAbfülllinie für PET (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2000, Overview

This complete filling line for single-use PET bottles was primarily manufactured in 2000 by the German company KRONES. The line previously operated as a disposable bottle filling system and was converted to accommodate single-use bottles in 2007. It is designed for high-performance beverage production with a capacity of up to 36,000 bottles per hour and is in good condition, suitable for 24/7, three-shift operations.

Technical Specifications

- Capacity: 36,000 bottles/h (at 0.33L)

- Bottle sizes: 0.33L and 0.5L

- Packaging formats: Shrink film with carry handle

Podpfx Afeyb R U Ho Negg

- Application: CSD

- Hygienic design

- Condition: installed, good technical condition

Scope of Supply

- Preform feeding system | SIG Coroplast/KHS | 2007

- Blow molder | SIG Coroplast/KHS | Blomax 20 | 2007

- Compressor | LMF | 2007

- Rinser | Krones | Variojet | 100 stations | 2000

- Filler/capper | Krones | Sensometic VP-IM | Capacity: 36,000/h | 2000

- Cap inspection | Heuft | 2000

- Dryer | Krones | 2013

- Labeler | Krones | Solomatic 1200-25-6-5-160 | 2013

- Shrink packers (2x) | Kettner | TFS 60 | 2000

- Crate packer | Kettner | 2000

- Tray coders (2x) | Bluhm Linx 8900 | 2019

- Handle application | PAD/Kettner | 2000

- Pallet wrappers (2x) | Kettner/Krones | 2000

- Pallet labeling | Logopak | 2000

- Loader | Kettner/Krones | 2000

- Mixer | Krones/Anton Paar | 2000

- Flash pasteurizer (KZE) | GEA Tuchenhagen | 2000

Mažas skelbimas

Menslage

Menslage

1 081 km

"Hamba BK 8008 P" pildymo linija (2002 m.)

HambaAbfülllinie

Skambinti

Sąlyga: naudotas, Gamybos metai: 2002, Overview The cup filling line was built in 2002 by SIG HAMBA, remains in operation until the end of 2024, and can be inspected at any time. Technical Specifications Capacity: 7,200 – 19,200 containers/h Cup formats: Cup diameter: 95 mm Max. height: 140 mm Filling ranges: Doser 20 ccm to 200 ccm fill Doser 200 ccm to 500 ccm fill Spare position Sealing: Foil and snap-on lid Siemens S7 control system Scope of Delivery Filling machine | SIG HAMBA | BK 8008 P | 2002 Cup destacker | Schäfer und Flottmann | SFS 337 | 2002 Empty carrier conveyor | Manex | – | 2002 Carton packer | AF | – | 2002 Integrated into SIG HAMBA BK 8008 P line Well maintained condition Full carrier conveyor | Manex, Sema | Manex Elevator | 2002 Layer palletizer | Manex | – | 2002

Pedpfxst Uw E Re Af Nogg

Mažas skelbimas

Menslage

Menslage

1 081 km

Krones Kosme, Gera, BMS stiklo butelių (daugkartinių) pilstymo linija (2012)

KronesAbfülllinie für Glasflaschen (Mehrweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2012, Overview The Krones, Gera, Joha, Markl, Miho returnable glass bottle filling line was previously used for bottling beer at a brewery in Southern Germany. Technical Data Capacity: 7,800 bottles/hour Products: beer and KEG Formats: NRW 0.5 l, 0.33 l, ring-neck 0.25 l LN Machine List Machine type: Depalletizer Manufacturer: BMS Year of manufacture: 2012 Machine type: Decapper (screw cap) Manufacturer: Rink Decapping in crate Euro 0.5 l in 4x5 crate Year of manufacture: 2012 Machine type: Bottle washer Manufacturer: Gera Year of manufacture: 2024 Machine type: Empty bottle inspector Manufacturer: Krones Model: Smarttronic incl. pusher Year of manufacture: 2012 Machine type: Filler Manufacturer: Kosme Model: Isofill G 28/960 28 valves Year of manufacture: 2012 With combi capper, 4 heads (crown cork and screw cap) Capacity: 7,800 bph Machine type: Labeller Manufacturer: Krones Model: Robusta Refurbished in 2012 10 bottle plates 2 labelling stations with 4 grippers and 4 glue pallets Inkjet printer Machine type: Packer Manufacturer: BMS Year of manufacture: 2012

Podpfx Afjyb Sbue Njgg

Mažas skelbimas

Menslage

Menslage

1 081 km

SIG Corpoplast, KHS Sacmi, Kisters ir kitos PET (vienkartinio naudojimo) pilstymo linijos (2000 m.)

SIG Corpoplast, KHSAbfülllinie für PET (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2000, Overview

This complete PET bottling line was manufactured between 2000 and 2012 by a group of renowned European manufacturers, including SIG Corpoplast, KHS, Sacmi, Kisters, Paxona, and others. The line is suitable for both still and carbonated soft drinks and comprises a stretch blow molding machine, filler, labeller, packaging machine, as well as various conveying and inspection systems. The system achieves an output of up to 36,000 bottles per hour at 1.5 L and is immediately available. All machines are well maintained, equipped with original components and corresponding peripheral devices.

Technical Data

Capacity:

- 36,000 bph at 1.5 L water

Pgsdpfxswh U Avj Af Njg

- 35,000 bph at 1.5 L sweetened soft drinks

- 32,000 bph at 1.5 L light soft drinks

Formats: 0.5 L and 1.5 L bottles

Closure: PCO 28-1881 screw cap

Filling products: Water and carbonated soft drinks (7.5g CO₂)

Closure system: Screw caps, cap feed via chute and tipper (Zalkin + NSM)

Packaging: Shrink film: 3x2 bottles (double-lane)

Pallet types: Euro pallet (1,200 x 800 mm), Düsseldorf pallet (600 x 800 mm)

Electrical data: 400 V / 50 Hz

Controls: ABB, Siemens

Operating direction: Standard

Scope of Delivery

- Stretch blow molder: SIG Corpoplast Blomax 24, year 2008, 24 stations, oven with 20 boxes, ABB control, including preform tipper MD3, preform hopper SBT, elevator HFT, conveyor RGTD, chute ASTK

- Air conveyor: NTS Mistral, year 2000, pneumatically adjustable rails, basket cable tray

- Filler: KHS Innofill EV-VF, year 2000, 176 electronic filling valves, valve manifold (APV), air conveyor, infeed screw, clamp star

- Capper: Zalkin, 22 heads; cap feed (NSM); foam cleaning (ECOLAB, 2001); dosing units (2011)

- Mixer/Deaeration: KHS Innopro DX65 Contimix 65/5-T20, year 2000, 65,000 l/h, 5 components, Brix meter (Anton Paar), Hilge pumps

- Labeller: Sacmi Opera 300 RF 26T/R S1E1, year 2012, 26 plates, hotmelt, wrap-around, roll-fed, parallel feed, safety lift model

- Inspection & Coding: Fill level and closure control: KHS Innocheck CUB Vision Circle, year 2013; bottle laser coding: Videojet with enclosure; packaging inspection: KHS Innocheck CUB, year 2015

- Packaging machine: Kisters SP060V, year 2000, shrink packer 3x2 (double-lane), 60 cycles/min, manual lane width adjustment, film only

- Conveyors & Pack Labelling: Bottle conveyor: KHS Innoline BTR, year 2000, plastic chain, dry lubrication; pack conveyor: Paxona + Schaefer, year 2009; pack labelling: Contact 100, self-adhesive label from roll

Mažas skelbimas

Menslage

Menslage

1 081 km

Breitner BFC, MDL, SRT maisto pildymo linija (2013)

BreitnerAbfülllinie

Skambinti

Sąlyga: naudotas, Gamybos metai: 2013, Overview

Complete filling line from the food sector by German manufacturer Breitner (2013). Previously used for filling liquid cheese products and sealing with press-on and screw caps. Spray pumps with dip tubes can also be processed. Additional features such as a laminar flow system and special focus on hygienic design achieve cleanroom classification.

Psdpexqzmwefx Af Negg

Machines:

Pos. 1 Bottle Unscrambler Breitner BFC 8002 (2013), 6,000/h

Pos. 2 Filling Machine Breitner MDL 2086 (2013), 5,000/h

Pos. 3 Rotary Capping Machine Breitner SRT 5044 (2013), 5,000/h

All conveyors: chain width: 82.5 mm, AISI 304

Unsealed containers: Plexiglas cover

Bottle and cap formats:

Our service: Send us your requirements and we will verify the feasibility for processing your bottle format.

Cap formats: screw caps, press-on caps, spray pumps with dip tubes

1. Bottle Unscrambler BREITNER BFC 8002

Operation: continuous from storage hopper

Hopper volume / drum Ø: 1.4 m³ / 1500 mm

Operating height: 900 mm, left → right

Material / housing: AISI 304 stainless steel + Plexiglas

Safety: door switch, overload protection

Power / air: 3 × 400 V, 4 kW / 400 Nl/min at 6 bar

Container size: round Ø ≤100 mm × 250 mm, larger on request

Feature: Ionized air cleaning station with dust extraction

2. Filling Machine BREITNER MDL 2086

Filling method: mass flow, 8 stations (expandable to 12)

Filling range: 100 – 2000 ml/g, up to 5,000 bottles/h

Operating height/direction: 900 mm, left → right

Product-contact parts: AISI 316, food-grade hoses, VITON seals

Tank / pressure: 100 L, 5 bar

Electrical / air: 3 × 400 V, 4 kW / 150 Nl/min at 6 bar

Container size: H 50–350 mm, Ø/width 50–80 mm, various shapes

CIP cleaning: automatic cleaning & draining, multi-stage program

Extras: laminar flow, remote maintenance, additional filling valves, swiveling tray, heating system

3. Rotary Capping Machine BREITNER SRT 5044

Operation: continuous rotary, 4 capping stations

Capacity: up to 5,000 containers/h

Container size: Ø ≤100 mm, H ≤300 mm

Operating height / direction: 900 mm, left → right

Drive / tools: servomotor, 0.3–3.5 Nm; BREITNER capping tools

Power / air: 3 × 400 V, 4 kW / 100 Nl/min at 6 bar

Control: B&R control, touchscreen, 200 format memory, password protection

Safety & inspection: door switch, overload, "no bottle – no cap", optical cap inspection, ejection system

Extras: servo vertical movement, torque monitoring, fan-assisted cap feeding, vibration sorter, cap feeder

Mažas skelbimas

Menslage

Menslage

1 081 km

SIDEL Sidel, Krones, SIG Simonazzi užpildymo linija stiklinėms buteliams (vienkartinė) (2003)

SIDELAbfülllinie für Glasflaschen (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2003, Overview This complete filling line for disposable glass bottles was manufactured in 2003 by several renowned European producers, primarily Sidel. The line is designed for high-performance beverage production with a capacity of up to 40,000 bottles per hour. It is in good condition and is designed for 24/7 operation in 3 shifts.

Technical Data

Capacity: 40,000 bottles/h (at 0.25L)

Bottle formats: 0.25L, 0.33L, 0.5L

Packaging formats:

- 4x6 x 25cl

- 1x12 x 25cl

- 24x25cl

- 24x30cl

- 4x6 x 33cl

- 6x4 x 33cl

- 1x12 x 33cl

- 24x33cl

- 20x50cl

Application: Beer, CSD, or other beverages in disposable glass bottles

Hygienic design

Automated format changeover

Scope of Supply

Pallet Conveyor (Depalletizer) | Sidel / SIG Simonazzi / GEBO | 2003 | SWEEP-OFF/B

Bulk Depalletizer | Sidel / SIG Simonazzi / GEBO | 2003 | SWEEP-OFF/B

Pallet Conveyor (Palletizer) | Sidel / SIG Simonazzi | 2003 | LINEAR

Tray and/or Carton Palletizer | Sidel / SIG Simonazzi | 2003 | LINEAR

Pallet Shrink Wrapping Machine | Sidel / SIG Simonazzi / MSK | 2003 | ECONOTECH/TOWERTECH

Pallet Labeler | Sidel / SIG Simonazzi / Logopak | 2003 | LOGOMATIC 920 II PF

Crate Erector | Sidel / SIG Simonazzi / H&B Schleuter | 2003 | TLA

Four-pack Conveying and Divider | Sidel / SIG Simonazzi / H&B Schleuter | 2003 | TLW

Crate Inserter | Sidel / SIG Simonazzi / H&B Schleuter | 2003 | TLE

Carton Packer | Sidel / SIG Simonazzi / FANUC | 2003 | ROBOKOMBI

Carton Sealer | Sidel / SIG Simonazzi / Bortolin | 2003 | MARA H.M

Carton Coder 1 | Sidel / SIG Simonazzi / Domino | 2003 | A-Series Inkjet Printer

Carton Coder 2 | Sidel / SIG Simonazzi / Domino | 2003 | A-Series Inkjet Printer

Checkweigher | Prisma | 2003 | 10D3

Full Carton Inspection | BBull / Centro Kontrollsysteme | 2015 | Image VKK 500

Bottle Conveyors | Sidel / SIG Simonazzi | 2003 | TRANSPORT

Carton Conveyors | Sidel / SIG Simonazzi | 2003 | TRANSPORT

Crown Cap Feeder | Sidel / SIG Simonazzi | 2003 | SM80

Rinser | Sidel / SIG Simonazzi | 2003 | EUROTRONICA LP

Filler | Sidel / SIG Simonazzi | 2003 | EUROTRONICA LP

Crowner | Sidel / SIG Simonazzi | 2003 | EUROTRONICA LP

C.I.P. | Sidel / SIG Simonazzi | 2003 | AUTOSAN

Fill Level Control | Sidel / SIG Simonazzi / Heuft | 2003 | SPECTRUM TX

Tunnel/Bottle Pasteurizer | Sidel / SIG Simonazzi | 2003 | PAMA CLD 50/144

Pgodpsyb Tucofx Af Nog

Bottle Neck Code Printing | Mundi-Technology | 2015 | Mundiscan UP2000 HE

Labeler | Sidel / SIG Simonazzi / Krones | 2003 | Topmodule Type 407

Bottle Inspection & Sorting | Sidel / SIG Simonazzi / Krones | 2003 | Checkmat Type 707

TapTone | Sidel / SIG Simonazzi / Krones | 2003 | TapTone 500 Series

Mažas skelbimas

Menslage

Menslage

1 081 km

M+F KEG-Technik M 2/2 KEG užpildymo linija (2009)

M+F KEG-TechnikKEG Abfüllanlage

Skambinti

Sąlyga: naudotas, Gamybos metai: 2009, Apžvalga: Ši KEG užpildymo linija Micromat 2/2-b buvo pagaminta M+F KEG Technik 2009 m. Ją sudaro KEG plovimo įrenginys ir KEG užpildymo įrenginys. Iki išmontavimo buvo naudojama alaus darykloje Belgijoje. Techniniai duomenys: Našumas: 20–35 KEG/val., KEG tipas: 20 l/30 l DIN ir EURO, Sąsajos tipas: tipo S, 1 stotis: vidaus valymas, 2 stotis: skalavimas, sterilizavimas ir užpildymas. Pusiau automatinė linija su integruota CIP sistema, CIP talpykla montuota įrenginio gale. Matmenys: ilgis – 1 100 mm, plotis – 1 300 mm, aukštis – 2 200 mm +/- 50 mm. Elektros prijungimas: Įtampa 230/400 V, 50 Hz, 3 fazės, Galingumas: 0,5 kW (be rezervuaro siurblių).

Psdpfx Aexrfcxof Negg

Mažas skelbimas

Menslage

Menslage

1 081 km

KHS Innofill skardinių užpildymo linija (2017 m.)

KHSAbfülllinie für Dosen

Skambinti

Sąlyga: naudotas, Gamybos metai: 2017, Overview

This complete beverage can filling line was manufactured in 2017 by the German producer KHS. The line is designed for beverage production with an output of up to 25,000 b/h and is in good condition.

Technical Data

- Output: 25,000 bph (at 0.5L)

- Fill product: Carbonated soft drinks and beer

- Can formats: 500ml 211/202

- Closure types: 211/202

- Packaging formats: Tray with film

- Application: KEG + beer

- Condition: Good technical condition, dismantled

Scope of Delivery

- Can depalletizer | LINKER | DPG-500 | 2012

- Can inspection | TransTech | Hysek CanCheck | 2012

- Can conveyor | LINKER / KHS | Conveyor RC | 2012

- Rinser | LINKER / KHS | Triplex Rinser TR | 2012

- Flash pasteurizer | KHS | Innopro 140/14/85 | 2012

- Filler | KHS | Innofill Can DVD | 2017

Podeyb R Srjpfx Af Nsgg

- Seamer | Ferrum | F08 | 2012

- Lid feeder | NSM | Lidserver A30 | 2017

- Conveyor | KHS | Innoline BTR | 2012

- Fill level inspection | KHS | Innocheck CUB | 2012

- Blow-off unit | Europool | -

- Packaging machine | KHS Kisters | SP0502 | 2012

- Pack conveyor | KHS | Innoline GTR | 2012

- Handle applicator | KHS | CSM 050-2 | 2012

- Packaging machine | KHS | Innopack 035 B2 + FS A-L | 2012 / 2017

- Palletizer | KHS | Innopal PBL1N1 | 2012

- Stretch wrapper | SIAT | MFP | 2017

- Pallet conveyor | KHS | Innoline PTR

Mažas skelbimas

Menslage

Menslage

1 081 km

"Steelhead EUROPA 2 Wide" išpilstymo linija (2003 m.)

SteelheadAbfülllinie

Skambinti

Sąlyga: naudotas, Gamybos metai: 2003, Overview This 5-gallon water bottling machine was built in 2003 using proven technology by the American manufacturer Steelhead. The machine has already been dismantled, stored, and can be viewed in person. Technical Details. Capacity: 600 bph

Pedpfjtw Ip Tox Af Nogg

Mažas skelbimas

Menslage

Menslage

1 081 km

SEN - Pripildymo linija (1998 m.)

SENAbfülllinie

Skambinti

Sąlyga: naudotas, Gamybos metai: 1998, Overview

The bottling line is located at a German winery and is no longer in operation. It is available because the seller has purchased a larger unit. Bottling was done in 1-liter Schlegel bottles with MCA closure.

Pgsdjl Hx H Njpfx Af Nsg

System details

Bottle Washer

Manufacturer: SeitzEnzingerNoll

Year of manufacture: 1988

Type: TAUCH + STELLA

Drying Tunnel

Manufacturer: SeitzEnzingerNoll

Year of manufacture: 1987

Type: REGA1

Filler

Manufacturer: Sen

Model: compacta-h with 12 bottle stations

Few operating hours

Screw Capper

Manufacturer: Adelski

Year of manufacture: 1998

Type: PP2001 S MCA capper

Labeller

Manufacturer: MAG

Year of manufacture: 2000

Sorting Table

Conveyor

Mažas skelbimas

Menslage

Menslage

1 081 km

ALWID ATEX pildymo linija (2021 m.)

ALWIDAbfülllinie

Skambinti

Sąlyga: naudotas, Gamybos metai: 2021, Overview

The filling line was manufactured in 2021 by the German company ALWID. The filling line is new and can fill chemical products into plastic containers. With the exception of the bottle infeed and Posimat, glass bottles can also be processed. Thanks to ATEX certification, the line is suitable for processing explosive products. The system comes with a 2-year warranty (single-shift operation), and all components can be purchased individually.

Technical details

Performance: 9,000 containers/h (varies depending on bottle volume and product)

Containers: Max. diameter: 100 mm, Max. height: 300 mm

Control system: Siemens S7

Individual machines

Bottle Unscrambler | ALWID | POSIMAT-ACCESS-N15

Bottle feeding system with 2000 l hopper, made of stainless steel, chassis and supports in painted mild steel

Positronic control system for optimal adjustment to downstream filler

Machine fully internally wired with attached control cabinet in painted mild steel

Machine compliant with CE regulations; i.e. max. noise level of ≤ 80 dB +/- 2

Combined filling and capping machine (block system) | ALWID | SUPERIOR-16MDM-5SK

Fully automatic rotary filler

Filling system: mass flow measurement system, type: Endress+Hauser LPG MASS

Number of filling stations: 16

Filling valve diameter: Ø12 mm

Max. container dimensions: Height: 50-300 mm, Ø: 20-100 mm

Fully automatic rotary capper

Number of capping heads: 5, with torque adjustment via slip clutches

With fully automatic cap sorting and feeding via BONINO disc sorter with elevator, including gravity chute switch for machine shutdown if caps are missing

Checkweigher | ALWID | OCS-HC-M-2000-1

Applied safety and machinery guidelines: CE compliant

Industrial load cell with stainless steel housing using electromagnetic force compensation principle

Force bypass-free current transmission at the load cell

Front cover to reduce external influences on weighing results

Stainless steel control cabinet

Graphical color TFT touchscreen, 10.4 inch, VGA resolution

Flexible operation via tiltable stainless steel control terminal

Freely configurable user interface for simple, intuitive operation

Inkjet printer | Domino | Ax350i

Fast printing of texts and multi-line codes at high speeds

Labeler | ALWID | SES-120-III tandem version

Max. label height: 120 mm

Podpfxsmfqm Do Af Nsgg

Photoelectric sensor for label detection

2 x automatic rewinding stations incl. counterpressure plate

Mounting device with height adjustment for side label dispensers

With adjustable side guides - passage width up to 150 mm

Conveyor system

Mažas skelbimas

Menslage

Menslage

1 081 km

SIPA, Procomac Falterbaum, Profipack PET (vienkartinio naudojimo) pilstymo linija (2000 m.)

SIPA, ProcomacAbfülllinie für PET (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2000, Overview

This complete PET bottling line was manufactured between 2000 and 2012 by renowned European producers. The plant is suitable for still and carbonated soft drinks and comprises a stretch blow-moulding machine with compressed air generator, rinser/filler/capper, labeller, packer, palletizer, wrapper, conveyor belts, inspection systems, mixing and CIP unit. The line achieves an output of up to 8,000 bottles/h at 1.5 L and is immediately available. All equipment has been well maintained and comes with original components and the corresponding peripheral devices.

Technical Data

Psdpfx Aewq Sfgsf Negg

Output: 8,000 bottles/h at 1.5 L

Formats: 0.5 L and 1.5 L bottles

Products: Water and carbonated soft drinks

Closure system: Plastic screw caps, sport caps

Packaging: Shrink wrapping: 3x2 formation for 0.5 L and 1.5 L PET bottles

Pallet type: Euro (1,200 x 800 mm); Düsseldorf (600 x 800 mm)

Scope of Delivery

- Stretch blow-moulding machine: SIPA, year 2002

- Compressed air generator: Kaeser, year 2002

- Rinser/Filler/Capper: Procomac, year 2000

- Number of rinsing nozzles: 24

- Number of filling valves: 24

- Number of capping heads: 6

- Labelling machine: Futura, year 2000 (for hot-melt wrap-around labelling)

- Inspection device: Logics & Controls, year 2000 (checks fill level, closures and labels)

- Shrink wrapper: Krones TFS Variopack, year 2001

- Handle applicator: Twinpack, year 2001

- Tray labeller: Logopack, year 2001

- Pallet stretch wrapper: Born, year 2001

- Palletizing system: Levanti / Profipack

- CIP unit: Corosys, year 2012

- CO2 degassing unit: Corosys, year 2012

Mažas skelbimas

Menslage

Menslage

1 081 km

EUROSTAR SKILLFILL DPS 24-24-6C stiklinių butelių pildymo linija (vienkartinė) (2014 m.)

EUROSTARAbfülllinie für Glasflaschen (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2014, Overview This complete isobaric bottling line was manufactured in 2014 by Italian producer Eurostar and is located in Mexico. The line comprises a triblock unit (rinser, filler, and capper), a self-adhesive labeling machine, and conveyor belts. The system is being sold due to the acquisition of a new, higher-capacity line. It has already been dismantled. Technical Details Capacity: Max. 6,000 bph Formats: 0.210 L, 0.355 L, 0.500 L glass bottles 26 mm metal crown caps Dimensions: Width: 5,300 mm Depth: 2,630 mm Height: 2,860 mm Weight: 8,000 kg POWER SUPPLY: Main supply: 460V - 60Hz - 3Ph+N+PE Auxiliary voltage: 24V DC Main drive motor: 4 kW Installed power: 9 kW Scope of Supply Triblock (rinser, filler, and capper) Self-adhesive labeller with 2 stations Conveyor belts

Psdpevm U Dljfx Af Nsgg

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Menslage

Menslage

1 081 km

Monoblokas VVF14/3 Pripildymo linija Stikliniai buteliai

H & KAbfülllinie für Glasflaschen (Mehrweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2016, Overview

The filling line for glass bottles (single-use and returnable) was in operation until recently at a small brewery in Germany. The system is designed for 0.33l longneck bottles and can fill up to 2,500 bottles per hour. The machine is still in operation and can be inspected by appointment at any time. The bottle washer and depacker can also be purchased separately.

Technical Details

Capacity: 2,500 bph

Formats: Set up for 0.33l longneck

Filling temperature: 6°C

Packaging:

- 0.33l longneck in 24-unit folding cartons

- 0.33l longneck in 24-unit modular crates

Pgjdel Hx Rpepfx Af Nsg

Individual Machines / System Components

- New glass depalletizer | Füllmeister | - | 2016

- Filler + Capper | H&K | VVF 14/3 | 1966

2016 major overhaul: with pre-evacuation, new rotary joint, new stainless steel table, new electrical system, new stainless steel control cabinet for the valves, 0.33 liter bottle guide set, Sihi vacuum pump, seals for lift cylinders and filling valves replaced in 2023, vacuum and overpressure valves fitted with new seals and springs in 2023

- Bottle Depacker | Joha | - | 1982

Pack head for 24 bottles in modular crate

- Bottle Washer | Silmo | Praktika | 1983

Bottles per row: 12

- Labelling unit | Krones | Vinetta | 1999

Type 480-6-3-180

Labelling stations for back labels, front and neck ribbons, each with three glue pallets and gripper sponges, glue pallets, gripper sponges, and sponge roller at the bottle outfeed replaced new in 2023, glue pump Krones Unipump-H with glue heater

- Packer | Pexco | - | -

1 head for 24 bottles in modular crates; new electrical system installed and machine overhauled in 2016

- Residual liquid and mouth control | Miho | LC2000 |

Residual caustic detection from bottle washer, control of bottle mouth for crown caps/metal, incl. Silmo inspection screen for visual inspection of cleaned bottles

- Crate Washer | Fleischer | - | -

For cleaning empty plastic crates via in-line process, module size: 300x400mm, overhauled in 2016

- Compressor | Alup | Allegro 19-10 | 2016

Oil-free, 4,897 operating hours

Transport

- Bottle transport: various conveyor belts + 90° bends

- Crate transport / roller conveyor: overhauled in 2016 with stainless steel side rails and legs

Mažas skelbimas

Menslage

Menslage

1 081 km

Cimec Monobloc 16-16-1 užpildymo linija stikliniams buteliams (vienkartiniams) (2014)

CimecAbfülllinie für Glasflaschen (Einweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2014, Overview This complete glass bottling line was manufactured between 2010 and 2014 by several renowned European producers, including CIMEC (Italy). The main unit—a CIMEC 16-16-1 rinsing, filling, and capping monoblock—was built in 2014 and operated in a natural mineral water facility until July 2025. The line also includes additional equipment such as self-adhesive and wrap-around labelers, a DE filter, and a heat shrink tunnel for capsules, making it a fully operational and compact bottling system for glass bottles with crown caps. All equipment remains installed, is in good condition, and can be inspected on-site. Technical Data Years of manufacture: 2010–2014 Application: Water and other beverages Capacity: Approx. 2,000 bottles per hour (330 ml) Approx. 1,670 bottles per hour (500 ml) Bottle formats: 250 ml – 1,000 ml (including: 330 ml & 500 ml) Closure type: 26 mm crown caps Configuration (monoblock): 16 rinsing heads 16 filling heads 1 crowning head Scope of delivery Rinser / Filler / Crowner Monoblock | CIMEC | Monobloc 16-16-1 | 2014 | 16/16/1 configuration, 26 mm crown cap, 2,000 bph Self-adhesive labeler | Canellitech | V500 | 2012 | Linear, up to 3,500 bph Single-head labeler (wrap-around) | Identapply | Servo 125 RH | 2010 | With conveyors DE filter | Spadoni | – | 2011 | 80 hl/h Heat shrink tunnel for capsules | TOSA | TN1 | 2011 | For PVC capsules

Pgodeyb Tkdepfx Af Nog

Mažas skelbimas

Menslage

Menslage

1 081 km

Linapack, Kreuzmayr LFS 1000 linija maišelių pakavimui (2018 m.)

Linapack, KreuzmayrLinie für Beutelverpackungen

Skambinti

Sąlyga: naudotas, Gamybos metai: 2018, Overview

The offered pouch filling line was designed by a Swiss company and delivered in 2018. The main manufacturer is Linapack. The line was only used for seasonal production (2 months a year), therefore operating hours are very low. As sales figures have not further increased, the seller has decided to sell the system and cease production. The line is still installed and can be inspected. It is capable of processing various pouch formats and allows hot filling up to 85°C. The current owner used it for cocktails, but it can also be used for various other non-carbonated beverages.

Technical details

- Capacity: 50 pouches/hour, depending on volume 750 - 900 l/h

- Pouch dimensions: width 80 - 180 mm, height 100 - 300 mm

- Filling temperature: 71 - 85°C

- Siemens PLC

The line consists of:

- 1,000 l buffer tank

- Agitator

- Flow meter

- Level detection

- Cleaning spray ball integrated in pasteurization control

Short-time heating unit

- Kreuzmayr PAS-900

- Capacity: 750 - 1,000 l/h

- Steam heated

- Fully automatic

- Automatic cleaning with hot water, steam, acid, caustic

- With tube heat exchanger

Automatic filler Linapack LFS-1000 Duplex with Siemens PLC

- Seven-station system

- Motorized magazine with pick-and-place system for pouch feeding

- Opening of pouches using vacuum grippers

- Filling unit with flow meter and temperature sensor, automatic rejection if the temperature is too low

- Sealing of pouches

- Cooling of seals

- Emptying of pouches

- Checkweigher

- Pouch chiller and dryer

Pgodpfevptt Rox Af Nog

- Water bath cooling

- UV lamps for sterilization

- Drying by blower with five nozzles

- Conveyor belts and collection table

Mažas skelbimas

Menslage

Menslage

1 081 km

RICO, ADELSKI, PAC SYSCONA, ICS, ANKER, Keyence stiklinių butelių pildymo linija (daugkartinio naudo

RICO, ADELSKI, PACAbfülllinie für Glasflaschen (Mehrweg)

Skambinti

Sąlyga: naudotas, Gamybos metai: 2011, Overview

This complete bottling line was designed for NRW and Euro bottles as well as crates and pallets, offering a capacity of up to 7,500 bottles per hour. The machines are from various years of manufacture between 1992 and 2022 and have low operating hours. The system remains in operation until the end of May and can be inspected in person.

Technical Details

Capacity: Up to 7,500 bottles/hour

Processed bottle formats: 0.33L & 0.5L (NRW, Euro, Ale)

Processed crate formats: NRW and Euro crates

Scope of Delivery

- Depalletizer & Palletizer | Flema | Star C-LC | 1996 (500 crates/h)

- Unpacker | RICO | UNO 1-Head 124 | 2010 (350 crates/h)

- Descrew/Decorker | ADELSKI | PPE 2005 | 1995 (2,000–12,500 btls/h, 8,500 operating hours)

- Bottle Washer | PAC | CB 14-0.5l-R-7 LII Compact | 1998 (7,500 btls/h, 14,175 operating hours)

- Bottle Inspection | SYSCONA | LC 10 FD | 2007 (caustic inspection & metal detection)

- Filler | ICS | multiFILL-VST (EP) 960-24-240-6KK-6SV-125.6 | 2011 (6,000 btls/h, 7,200 operating hours)

- Labelling Machine | ANKER | Roland 8/3 | 1998 (7,000 btls/h, 14,500 operating hours)

- Inkjet Printer | Keyence | MK-G1000 | 2022 (currently set up for dating on the ANKER Roland 8/3 labeller)

- Packer | RICO | UNO 1-Head L-Machine | 2012 (300 crates/h)

- Premixer | Jakü | PM-E-30-2k | 1992 (35 hl/h, degassing & carbonation)

Pgedpfjv Icubex Af Nsg

- Crate Washer | RICO | 2500 1-Bath | 2012 (600 crates/h)

- CIP Tanks | - | - | 2012 (2x 6 hl, steam heated)

Palengviname jums paiešką: "linija"

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota Linija (2 774)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- Analitinės Svarstyklės

- Ekstruzijos Linijos

- Gamybos Linija

- Gamybos Įrenginys

- Krašto Klijų Aparatas

- Linijinis Pašarų

- Linijos Anga

- Linijos Tekinimo Staklės

- Maisto Gaminimo Linija

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo