Iškirpti Su Ilgio Linija pirkti naudotą (14 806)

Strenči

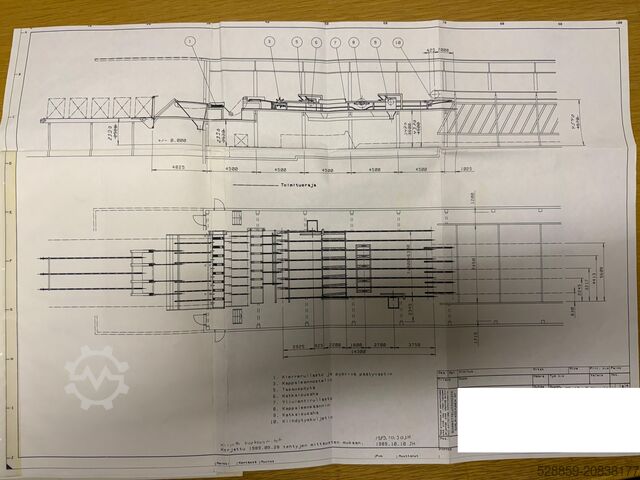

Strenči Lentos rūšiavimo linija

Mierzęcice

Mierzęcice Lakštinio metalo pjaustymo linija lapams/formatams

Sestal

Åsby

Åsby Rąstų rūšiavimo linija

Ingvar Persson ABKSAB 4000

+44 20 806 810 84

Vokietija

Vokietija Gamybos linija

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Rzeszów

Rzeszów Tešlos linija

Seewer RondoRondoline

Atraskite daugiau naudotų mašinų

Rzeszów

Rzeszów Duonos linija, ciabatta

KönigLIPPELT RUSTICA

Bremen

Bremen 9140 litrų vakuuminis indas su viduje esančia pilno ilgio V2A vamzdine spiralė

9338

Menslage

Menslage "Hamba BK 8008 P" pildymo linija (2002 m.)

HambaAbfülllinie

Menslage

Menslage Klinger, Krone, Nate ir kiti stiklo butelių užpildymo linija (daugkartinio naudojimo) (2004)

Klinger, Krone, NateAbfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage Krones Heuft-KHS-SIG Coroplast PET (vienkartinio) užpildymo linija (2000 m.)

KronesAbfülllinie für PET (Einweg)

Menslage

Menslage Krones Kosme, Gera, BMS stiklo butelių (daugkartinių) pilstymo linija (2012)

KronesAbfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage Siapi, Melegari, PE Comag, TMG, Domino, Atlanta PET (vienkartinė) išpilstymo linija (2008)

Siapi, Melegari, PEAbfülllinie für PET (Einweg)

Menslage

Menslage SIG Corpoplast, KHS Sacmi, Kisters ir kitos PET (vienkartinio naudojimo) pilstymo linijos (2000 m.)

SIG Corpoplast, KHSAbfülllinie für PET (Einweg)

Menslage

Menslage SEN - Pripildymo linija (1998 m.)

SENAbfülllinie

Menslage

Menslage Breitner BFC, MDL, SRT maisto pildymo linija (2013)

BreitnerAbfülllinie

Menslage

Menslage M+F KEG-Technik M 2/2 KEG užpildymo linija (2009)

M+F KEG-TechnikKEG Abfüllanlage

Menslage

Menslage KHS Innofill skardinių užpildymo linija (2017 m.)

KHSAbfülllinie für Dosen

Menslage

Menslage ALWID ATEX pildymo linija (2021 m.)

ALWIDAbfülllinie

Menslage

Menslage "Steelhead EUROPA 2 Wide" išpilstymo linija (2003 m.)

SteelheadAbfülllinie

Menslage

Menslage SIPA, Procomac Falterbaum, Profipack PET (vienkartinio naudojimo) pilstymo linija (2000 m.)

SIPA, ProcomacAbfülllinie für PET (Einweg)

Menslage

Menslage EUROSTAR SKILLFILL DPS 24-24-6C stiklinių butelių pildymo linija (vienkartinė) (2014 m.)

EUROSTARAbfülllinie für Glasflaschen (Einweg)

Menslage

Menslage SIDEL Sidel, Krones, SIG Simonazzi užpildymo linija stiklinėms buteliams (vienkartinė) (2003)

SIDELAbfülllinie für Glasflaschen (Einweg)

Menslage

Menslage RICO, ADELSKI, PAC SYSCONA, ICS, ANKER, Keyence stiklinių butelių pildymo linija (daugkartinio naudo

RICO, ADELSKI, PACAbfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage Shandong Yuesheng 14-12-6 stiklo butelių užpildymo linija (daugkartinis) (2019)

Shandong YueshengAbfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage Cimec Monobloc 16-16-1 užpildymo linija stikliniams buteliams (vienkartiniams) (2014)

CimecAbfülllinie für Glasflaschen (Einweg)

Naudota Iškirpti Su Ilgio Linija (14 806)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

+44 20 806 810 84