Evolution pirkti naudotą (778)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Mažas skelbimas

Lietuva

Lietuva

97 km

Dvigubas kampinis pjūklas medienai ir aliuminiui

PERTICI UNIVER332P

Skambinti

Sąlyga: naudotas, Gamybos metai: 2001, Funkcionalumas: visiškai funkcionalus, Dvi pneumatiškai nuleidžiamos galvutės su 330 mm skersmens pjūklais. Kairė galvutė – stacionari, dešinė – judanti. P modelių pjovimo galvutės pakreipiamos naudojant pneumatinį cilindrą. Įrengta „dviem rankomis“ valdoma valdymo sistema ir momentinio pjūklo sustabdymo įrenginys.

Bendros charakteristikos:

1. Varikliai – 2 vnt. x 1,1 kW, 380 V

2. Apsisukimų skaičius – 3765 aps./min.

3. Pjūklo skersmuo – 330 x 30 mm

4. Pjūklo galvutės posvyris – 90º–45º

5. Pasukimas – -45º–90º–45º

6. Didžiausias pjovimo ilgis – 3335 mm

Ijdpexytnljfx Abkstr

7. Mažiausias pjovimo ilgis (visuose modeliuose), kai galvutės pasuktos į vidų 45º – 420 mm

8. Mažiausias pjovimo ilgis, kai galvutės pjauna 90º kampu – 365 mm

9. Didžiausi, pjaunamų ruošinių, matmenys pjaunant 45º kampu (A x P) – 90 x 100 mm

10. Didžiausi, pjaunamų ruošinių, matmenys pjaunant 90º kampu (A x P) – 90 x 145 mm

Mažas skelbimas

Bydgoszcz

Bydgoszcz

442 km

Rankinis lazerinis suvirinimo aparatas 3000W

OtinusLWH-3000-N Relfar FWH20-S10A

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Handheld Laser Welding Machine LWH-3000-N Relfar FWH20-S10A

Scope of Delivery:

- Laser welding machine with cooling system

- Welding gun with adjustable focal length and accessory kit

- Fiber laser source from MAX Photonics or Raycus

- Automatic wire feeder

- Hose and cable set

- Starter pack with nozzles and protective lenses

Technical Parameters:

- Laser power: 3000 W

- Laser wavelength: 1064 nm

- Welding speed: up to 120 mm/s

- Power supply: 3x400 Hz

- Dimensions (with head mount): 630x1300x1500 mm

Included in the Price:

One-day operator training and machine commissioning

- Day 1 (up to 8 hours) – commissioning and training

Relfar FWH20-S10A Welding Head – Welding, Cutting, and Cleaning

The Otinus laser welding machines come with a range of nozzles and protective lenses. This makes the equipment extremely versatile and cost-effective, eliminating the need for a handheld plasma cutter or a separate device for rust and paint removal.

Operation:

Thanks to the revolutionary welding system, any operator can achieve excellent results after a short training period. The cable allows the welder to work freely at multiple points without moving the machine. The localized heat-affected zone prevents excessive deformation. Weld seams are applied quickly and efficiently, ensuring a strong and accurate weld joint.

Intended Use:

The laser welding machine is designed for professional use in workshops requiring high-quality, visually appealing weld seams.

Laser Source Specifications:

1000 W

- Carbon steel: up to 3 mm

- Stainless steel: up to 3 mm

- Aluminum: 2 mm

- Brass: 0.8 – 1 mm

1500 W

- Carbon steel: up to 4 mm

- Stainless steel: up to 4 mm

- Aluminum: 3 mm

- Brass: 1 mm

2000 W

- Carbon steel: up to 5 mm

- Stainless steel: up to 5 mm

- Aluminum: 4 mm

- Brass: 2 mm

3000 W

- Carbon steel: up to 8 mm

Iedeup Uzxepfx Abkotr

- Stainless steel: up to 8 mm

- Aluminum: 7 mm

Construction:

The gun cable enables maximum freedom of movement and simplifies welding in various positions. The built-in controller features a large, clear display and is intuitive to operate. The device is equipped with a powerful cooling system, allowing for reliable operation under demanding, three-shift working conditions.

Operating Principle:

The laser welding machine melts both the welding wire and the edges of the parts to be joined using laser heat. The beam is focused and directed at the welding wire, which is fed via the feeder, and at the contact point. By pressing the trigger, the welding gun must be guided along the weld line in sync with the wire feed speed. Constant operating temperatures for both the laser source and the gun are ensured by a water-cooling system. Both laser output and cooling are controlled by a controller, which regulates parameters according to user settings.

Mažas skelbimas

Europe

Europe

557 km

Perdavimo progresyvi servo presas

AIDADSF-TE4-20000-730-250 - 2000 ton

Skambinti

Sąlyga: beveik kaip naujas (naudotas), Gamybos metai: 2022, Funkcionalumas: visiškai funkcionalus, hidraulinio cilindro reguliavimas: 400 mm, spaudimo jėga: 2 000 t, eigos ilgis: 800 mm, stalo ilgis: 7 300 mm, stalo plotis: 2 500 mm, Typ: Exzenterpresse (Stanzpresse)

Hersteller: Aida

Modell: DSF-TE4-20000-730-250

Baujahr: 2022

Nennpresskraft: 2.000 t

Energie bei 15 Hüben/min: 630 kJ

Energie bei 28 Hüben/min: 390 kJ

Hübe pro Minute:

– Vollhubbetrieb: 3–28

– Pendelhub (bei max. Vorschub 105 mm): 3–50

Stößelhub: 800 mm

Stößelverstellung: 400 mm

Maximaler Abstand zwischen Stößel und Pressentisch: 1.200 mm

Lichte Weite zwischen den Ständern: 7.580 mm

Stößelabmessungen: 7.300 × 2.500 mm

Tischabmessungen: 7.300 × 2.500 mm

Abstand zwischen den seitlichen Ständern (Öffnung vorne–hinten): 3.650 mm

Hauptmotorleistung: 2 × 750 kW

Stößelverstellmotorleistung: 30 kW

Maximales Oberwerkzeuggewicht: 35.000 kg

Normale Stößelruhelage: Oberer Totpunkt (OT)

Gesamte Bremszeit bei 15 Hüben/min: 799 ms

Sicherheitsabstand: 1.278 mm

Sicherheitsbremsdruck: 105 bar

Stromversorgung (Drehstrom): 400 V, 50 Hz

Mindest-Luftdruckversorgung: 5,5 bar

Transfersystem:

- Vorschubhub, vorwärts (verstellbar): 0–1.200 mm

- Öffnungs-/Schließhub je Seite (Barhub, verstellbar): 0–1.020 mm

Iodpex Ifn Aofx Abkotr

- Hubhöhe (verstellbar): 0–350 mm

- Innenlichte zwischen den Bars im geschlossenen Zustand: 700 mm

- Maximale Öffnung zwischen den Bars (voll geöffnet): 2.740 mm

- Querschnittsabmessungen der Bars: 220 × 220 mm

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

Siedlce

Siedlce

352 km

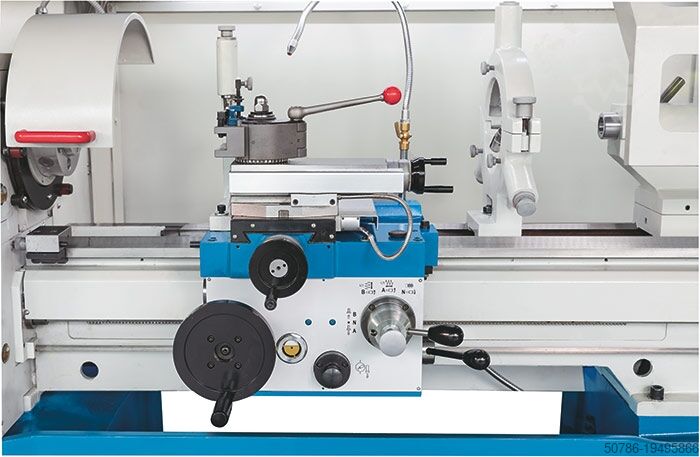

Universalus metalo tekinimo staklės

CORMAKTYTAN 750S

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Precision metal lathe TYTAN 750S 230V with spindle speed control via a DC inverter (frequency converter). Working parameters: turning diameter 220 mm, turning length 750 mm, motor power 1 kW at 230 V. The machine is suitable for machining external and internal cylindrical surfaces, threading, drilling, counterboring, and reaming. Ideal for use in small production facilities, workshops, or garages.

Machine Description

The TYTAN 750S 230V universal lathe, thanks to smooth spindle speed adjustment, is ergonomic and tailored to user needs. Less setup time when machining parts of various sizes translates into efficiency and user-friendliness.

S Version – electronic, stepless spindle speed regulation via a DC motor and voltage regulator. This ensures highest rotational accuracy of the chuck, delivering superior machining quality.

Main advantages:

Modern DC motor – with stepless spindle speed control for user convenience and reduced calibration time.

LCD display – features spindle speed readout for monitoring and quick modification of spindle revolutions during cutting and threading modes.

Two speed ranges – reduced (50-1125) for machining hard steels, increased (100-2500) for high-speed precision turning.

Threading capabilities – metric: 12 steps (0.4-3.5 mm), imperial: 12 steps (8-44 TPI) with the ability to cut both right- and left-hand threads.

Automatic feed – compliant with EU directives (CE), as well as Polish and DIN standards.

Full compliance – the machine is easy and convenient to operate.

Itedpfx Abjv Uplaskor

Machine base available optionally

Technical Specifications

Swing over bed: 220 mm

Swing over cross slide: 110 mm

Distance between centers: 750 mm

Bed width: 100 mm

Spindle bore: 38 mm

Spindle nose taper: MT5

Spindle speed adjustment: stepless

Spindle speed range: 50–2500 rpm

Number of metric threads: 12

Metric thread range: 0.4–3.5 mm

Number of imperial threads: 12

Imperial thread range: 8–44 TPI

Longitudinal feed range: 0.15–0.25 mm/rev (2)

Max tool post travel: 70 mm

Max cross slide travel: 80 mm

Max carriage travel: 630 mm

Tailstock quill travel: 60 mm

Tailstock taper: MT2

Main motor: 1000W

Tailstock bearing sleeve travel: 60 mm

Tailstock sleeve tip: MT2

Main motor: 1000W

Dimensions (L/W/H, w/o base): 1250 x 380 x 1100 mm

Weight (w/o base): 95 kg

Standard Equipment:

3-jaw chuck (125 mm)

Fixed and traveling steady rests

Change gears

Fixed center MT2

Fixed center MT4

Oil gun

Chip tray

Chuck and tool post wrenches

Operator tool set

CE-compliant safety guards

User manual in Polish

CE declaration of conformity

Optional Equipment:

Machine base

12x12 mm turning tool set (11 pcs. brazed carbide)

Live center MT2

Drill chuck arbor MT2/B16

HSS-CO5 cobalt drill set / 1-13 mm

Universal coolant system

ES-12 1L cutting oil/coolant

Mažas skelbimas

Wrocław

Wrocław

644 km

CNC apdirbimo centras

MorbidelliAuthor 503

Skambinti

Gamybos metai: 1994, Sąlyga: labai geros būklės (naudotas),

Atraskite daugiau naudotų mašinų

Mažas skelbimas

Trenčianske Stankovce

Trenčianske Stankovce

811 km

BILION H27400-2500T (2009 m.)

BILLIONH27400-2500T

Skambinti

Sąlyga: naudotas, Gamybos metai: 2009, Clamping Unit:

Clamping force: 2,500 t

Screw diameter: 145 mm

Tie bar spacing (vertical): 1,660 mm

Tie bar spacing (horizontal): 2,025 mm

Maximum clamping force: 25,255 kN

Minimum mold height: 830 mm

Maximum mold height (1): 1,900 mm

Maximum opening stroke: 2,780 mm

Overall platen dimension (horizontal): 2,800 mm

Overall platen dimension (vertical): 2,400 mm

Horizontal tie bar distance: 2,025 mm

Vertical tie bar distance: 1,660 mm

Maximum daylight between platens: 3,610 mm

Maximum opening speed: 600 mm/s

Maximum closing speed: 650 mm/s

Maximum opening force: 1,362 kN

Maximum closing force: 581 kN

Tie bar diameter: 380 mm

Ejector

Maximum stroke: 400 mm

Maximum forward force: 422 kN

Maximum return force: 284 kN

Maximum forward speed: 300 mm/s

Maximum return speed: 300 mm/s

Minimum forward and return speed: 10 mm/s

Injection Unit

Model: H 27400

Version: TP - SPR

Screw diameter: 145 mm

L/D ratio: 23

Itodpfx Ajx H Attobkor

Maximum theoretical displacement: 11,889 cm³

Maximum material pressure: 2,307 bar

Maximum injection flow rate: 2,311 cm³/s

Theoretical throughput per revolution (1): - cm³

Screw drive motor:

Nominal torque at 100%: 140 m.daN

Maximum screw stroke: 760 mm

Maximum screw advance speed: 140 mm/s

Injection unit stroke: -

With 1300T - 1600T - 2000T - 2500T: 1,200 mm

With: -

Nozzle touch force: 285 kN

Maximum injection unit forward speed: 150 mm/s

Maximum injection unit return speed: 150 mm/s

Note:

(1) Standard thermoplastic screw

Mažas skelbimas

Vokietija

Vokietija

6 514 km

Sriegimo valcavimo staklės

PROFIROLL BAD DUEBENPR 10 CNC AC

Skambinti

Sąlyga: naudotas, Gamybos metai: 1997, Techninės detalės:

Slėgis: 10 t

Itodpfx Aox Iu Ifobksr

Detalės skersmuo - maks.: 50 mm

Srieginio ilgio ilgis: 100 mm

Maks. valcuojamas žingsnis: 3 mm

Valcavimo jėga: 100 kN

Detalės skersmuo min./maks.: 117/175 mm

Sukimosi greitis: 0 - 150 aps./min

Mašinos svoris apie: 2550 t

Mašinos matmenys: 1,25 x 1,38 x 2,15 m

Mažas skelbimas

Lüneburg

Lüneburg

902 km

CNC tekinimo-frezavimo centras

Nakamura-TomeNTJX

Skambinti

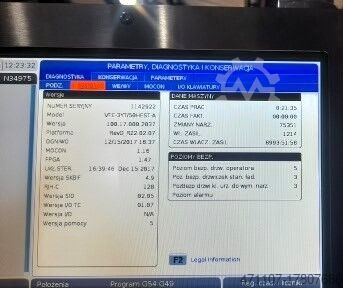

Sąlyga: naudotas, Gamybos metai: 2008, Funkcionalumas: visiškai funkcionalus, Tekinimo/frezavimo centras su priešpriešiniu velenu

su 10 CNC ašių (X1, X2, Z1, Z2, Y1, Y2, B1, B2, C1, C2)

Valdymas: FANUC 31:iA

Pagrindinis velenas

Veleno galia: 15/11 kW

Strypų skersmuo: 51 mm

Veleno apsisukimai: 5000 min-1

Priešpriešinis velenas

Veleno galia: 11/7,5 kW

Strypų skersmuo: 51 mm

Veleno apsisukimai: 50000 min-1

Tekinimo/frezavimo velenas

Galia: 7,5/3,7 kW

Apsisukimai: 12000 min-1

maks. tekinimo ilgis apatinis revolveris: 1005 mm

Iedpfx Ajx I N N Robkjtr

Stūmoklio eiga X1 / X2 / Z1 / Z2 / B2: 455 / 222,5 / 1090 / 1005 / 1008 mm

Stūmoklio eiga Y1/ Y2: + - 70 / + - 50 mm

B1 ašies pasukimo diapazonas: + - 95 °

Linijinis stelažinis žurnalas su palaikymo robotu

CNC atraminė liunetė

Aušinimo skysčio cikloninis filtravimo įrenginys su 2 aušinimo skysčio siurbliais

Veleno alyvos aušintuvas

Mažas skelbimas

Paszowice

Paszowice

691 km

Apdirbimo centras

HAASVF-3YT/50

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2017, veikimo valandos: 9 000 h, X ašies eiga: 1 016 mm, Y ašies eiga: 660 mm, Z ašies eigos atstumas: 635 mm,

Mažas skelbimas

Siedlce

Siedlce

352 km

Obliavimo staklės

CORMAKPT265 400V

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, The Cormak PT265 Planer-Thicknesser is a robust and well-engineered machine, offering extensive adjustment capabilities and mechanical processing of both hardwood and softwood. The adjustment itself is simple, and converting the planer to thicknessing operation takes just a few seconds.

Latest machine version with an innovative table opening system:

❌ Competing machines of the old type are fitted with “butterfly” tables. Before each job, the infeed and outfeed tables need to be recalibrated. Even small discrepancies between them lead to material damage and undesirable effects.

✔️ The new integrated table solution allows precise adjustment of both tables simultaneously! Once set, the tables remain permanently calibrated. When adjusting the planing height, both tables move in unison.

✔️ This innovation not only saves time and makes the machine more convenient to use, but also increases planing precision by 30% compared to previous systems. This is particularly important for working with thinner materials.

Stable, vibration-resistant construction

The machine’s weight of up to 170 kg, combined with wide, 265 mm precision-ground cast iron tables, ensures high stability and safe operation.

Additional rubber feet ensure operation is virtually vibration-free.

VERSION with the most powerful motor: S6 2.6 kW total output

The PT265 Planer-Thicknesser stands out with its exceptionally powerful S6-rated 2.6 kW motor (2.2 kW S1). This is significantly more than most competitor machines, resulting in higher performance and stable operation.

A more powerful motor means smooth operation and effortless processing of hard materials: Hardwoods require greater force to machine. The powerful motor handles this with ease.

Effortless changeover from jointer to thicknesser.

Switching from jointer to thicknesser mode is quick and straightforward—simply release the eccentrics, raise the tables, and reposition the chip extraction cover.

Precision working.

- Smooth height adjustment of tables with a scale.

- Thicknesser table is centrally mounted on a column and features an adjustment handwheel.

- Aluminum tilting fence (700x150 mm) with scale strip for precise adjustment between 90-45 degrees.

Technical data:

Cutterhead diameter [mm]: 75

Cutterhead speed [rpm]: 4000

Extraction port diameter [mm]: 100

Itjdpfxsvxhzns Abker

Tilting fence angle [°]: 0 - 45

Number of knives: 3

Cutterhead length [mm]: 262

Knife dimensions [mm]: 2500x300x30

Maximum planing width [mm]: 265

Maximum thicknessing width [mm]: 265

Maximum planing height [mm]: 180

Maximum thicknessing depth of cut [mm]: 3

Maximum planing depth of cut [mm]: 2.5

Thicknesser feed speed [m/min]: 6

Fence dimension [mm]: 700 x 150

Machine dimensions (L x W) [mm]: 1080 x 269

Weight [kg]: 170

Total motor power S6: 2.6 kW

Power supply: 400V

Mažas skelbimas

Wymysłów

Wymysłów

504 km

Popieriaus grąžtas

16 Hang106DTK4

Skambinti

Sąlyga: labai geros būklės (naudotas), Four-head paper drill.

Multiple units available!!!

Brand: Hang

Model: 106DTK4

Details: 4-head paper drilling machine with adjustable drilling heads

Iedpfx Abjudl Iksketr

Operation: Electric foot switch, 2 speeds

Available immediately

These additional details are standard for this model. Always verify specifics carefully during inspection.

The Hang 100DTK4 printing machine from 1975 is an iconic and reliable piece of equipment that made a significant impact in the printing industry. Manufactured by Hang, this machine offered advanced features for its time and set a benchmark for high-quality and efficient printing.

The Hang 100DTK4 is characterized by its robust and durable construction, ensuring stability and consistent performance throughout the printing process. Its printing technology, while conventional by today's standards, enabled precise and sharp prints with satisfactory resolution for its era.

Equipped with user-friendly controls and mechanical automation, the machine provided programmable settings for various formats and print configurations. Operation required skilled operators capable of achieving precise and repeatable print results.

The printing press was suitable for various substrates, including paper, cardboard, and lightweight board, catering to a range of printing applications common at the time.

Launched in 1975, the Hang 100DTK4 showcased technological advancements of its era. Its lasting performance and contributions to the printing industry are noteworthy. While newer presses with advanced digital technology have emerged, the Hang 100DTK4 remains a historical symbol of efficiency and innovation in 1970s print production. This machine holds collector value and serves as a testament to the evolution of printing technology over the decades.

Mažas skelbimas

Brno-město

Brno-město

831 km

CNC staklės

GildemeisterMF Sprint 65

Skambinti

Sąlyga: reikia remonto (naudotas), Gamybos metai: 1999, Funkcionalumas: neveikiantis, Neveikianti mašina, reikia remontuoti arba naudoti dalims. Veleno gręžinys 65 mm. Didžiausias apdirbimo ilgis 120 mm. 2 x galvos. Įrankių skaičius: 2 x 8. Veleno apsukos 5.000 rpm. Mašinos matmenys: 7560 x 1645 x 1765 mm. Mašinos svoris apie 5000 kg. Siemens Sinumerik 840C, priešpriešinis velenas, 2 galvos, varomieji įrankiai. Strypų padavėjas 3000 mm, drožlių transporteris, įrankių laikikliai.

Iodpfx Absx Ew Hfjkjtr

Mažas skelbimas

Vokietija

Vokietija

6 514 km

Balansavimo staklės - vertikalios

SCHENKVM2/2

Skambinti

Sąlyga: naudotas, Gamybos metai: 2006, Techninės detalės:

Didžiausias balansavimo svoris: 50 kg

Balansuojamo kūno skersmuo: 0–800 mm

Balansavimo greitis: 120–1200 aps./min

Apsisukimų skersmuo: 800 mm

Itsdpfx Abex Hi D Sskor

Variklio galia: 2,2 kW

Mažas skelbimas

Rīga

Rīga

205 km

Žuvies perdirbimo mašina

KronitekPotato washer,peeler KPP400

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, mašinos/transporto priemonės numeris: KPP400, Allgemein:

Die Kartoffelwasch- und Schälmaschine ist ein fortschrittliches Gerät, das speziell dafür entwickelt wurde, Kartoffeln effizient und in großen Mengen zu reinigen und zu schälen. Sie revolutioniert die bisher arbeitsintensive und zeitaufwendige Vorbereitung von Kartoffeln und ist daher im Bereich der Lebensmittelverarbeitung unverzichtbar.

Wesentliche Merkmale und Vorteile:

Effiziente Reinigung und Schälung: Die Maschine nutzt rotierende Bürsten oder abrasive Flächen, um Schmutz, Rückstände und die äußere Schale der Kartoffeln wirkungsvoll zu entfernen. Durch das durchdachte Design wird ein gründlicher Reinigungs- und Schälprozess gewährleistet, wodurch Abfall minimiert und der Ertrag verwertbarer Kartoffeln maximiert wird.

Zeit- und Arbeitseinsparung: Durch die Automatisierung des Wasch- und Schälvorgangs reduziert diese Maschine den manuellen Aufwand und die benötigte Zeit erheblich. So können lebensmittelverarbeitende Betriebe große Kartoffelmengen zügig und gleichmäßig verarbeiten, was die Produktivität nachhaltig steigert.

Vielseitigkeit bei Kartoffelsorten: Die Maschine ist für verschiedene Kartoffelarten geeignet und kann unterschiedliche Größen und Sorten verarbeiten. Anpassungsmöglichkeiten gewährleisten eine einheitliche Schälung – unabhängig von Form, Größe oder Beschaffenheit der Kartoffel.

Isdjt A Ampopfx Abkstr

Schonende Verarbeitung: Trotz ihrer hohen Leistungsfähigkeit arbeitet die Maschine äußerst schonend, um Beschädigungen oder Druckstellen an den Kartoffeln während des Wasch- und Schälvorgangs zu vermeiden. So bleibt die Qualität und das Aussehen des Endprodukts erhalten.

Wassereinsparung: Viele moderne Kartoffelwasch- und Schälmaschinen verfügen über wasser¬sparende Funktionen, z.B. effiziente Wasserkreislaufsysteme, die den Wasserverbrauch beim Reinigungsvorgang minimieren. Dieser umweltfreundliche Ansatz ist ein wichtiger Bestandteil nachhaltiger Lebensmittelverarbeitung.

Fazit:

Die Kartoffelwasch- und Schälmaschine revolutioniert die Kartoffelverarbeitung in Großküchen und lebensmittelverarbeitenden Betrieben. Mit ihrer Effizienz, Vielseitigkeit und abfallreduzierenden Technik optimiert sie den Vorbereitungsprozess von Kartoffeln und trägt damit zu einer ressourcenschonenden und effizienten Lebensmittelproduktion bei – ganz im Sinne moderner Anforderungen der Lebensmittelindustrie.

Mažas skelbimas

Bydgoszcz

Bydgoszcz

442 km

SANDELYJE: Rankinis lazerinis suvirinimo aparatas 1000W

OtinusLWH-1000-N Gefasst SUP 20S

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Handheld Laser Welding Machine LWH-1000-N Gefasst SUP 20S

Scope of delivery:

- Laser welding machine with cooling system

- Welding gun with adjustable focal length and accessory kit

- MAX Photonics fiber laser source

- Automatic wire feeder

- Hose and cable set

- Starter kit with nozzles and protective lenses

Technical Specifications

- Laser power: 1000 W

- Laser wavelength: 1064 nm

- Welding speed: up to 120 mm/s

- Power supply: 230 Hz

- Dimensions (with gun holder): 630x1300x1500 mm

Included in the price:

One-day operator training and machine commissioning

- Day 1 (up to 8 hours) – Commissioning and training

Gefasst SUP 20S Welding Head – Welding and Cutting

The Otinus laser welding machines come supplied with a range of nozzles and protective lenses. This makes the device highly versatile and saves on costs—for example, by eliminating the need for a handheld plasma cutter.

Operation

Thanks to the revolutionary welding system, any user can achieve high-quality results after a brief training session. The cable allows the welder to work freely at various locations without needing to move the device. The small heat-affected zone minimizes excessive distortion. Weld seams are produced very quickly and efficiently, resulting in precise and robust welded joints.

Intended Use

The laser welding machine is designed for professional use in workshops that require high-quality, aesthetically pleasing welds.

Laser Source Specifications:

1000 W

- Carbon steel: up to 3 mm

- Stainless steel: up to 3 mm

- Aluminum: 2 mm

- Brass: 0.8 – 1 mm

1500 W

- Carbon steel: up to 4 mm

- Stainless steel: up to 4 mm

- Aluminum: 3 mm

- Brass: 1 mm

2000 W

- Carbon steel: up to 5 mm

- Stainless steel: up to 5 mm

Itodpshufigjfx Abker

- Aluminum: 4 mm

- Brass: 2 mm

3000 W

- Carbon steel: up to 8 mm

- Stainless steel: up to 8 mm

- Aluminum: 7 mm

Design

The gun cable provides a high degree of freedom of movement and makes welding in different positions easier. The built-in controller with a large, clear display is intuitive to operate. The device features a powerful cooling system that enables use under demanding conditions in three-shift operations.

Operating Principle

The laser welding machine melts the welding wire and the edges of the parts to be joined using laser heat. The beam is focused and directed toward the welding wire—which is fed through the automatic feeder—and the contact point. When the trigger is pressed, the welding gun must be guided along the weld line at the speed of the wire feed. A constant operating temperature for the laser source and welding gun is maintained by a water-cooling system. Laser output and cooling are monitored by a controller that regulates values according to user parameters.

Mažas skelbimas

Cloppenburg

Cloppenburg

1 065 km

2013 Göckel RB5

GöckelRB5

Skambinti

Sąlyga: naudotas, Gamybos metai: 2013, Suitable for grinding circular knives and all types of blades.

Accessories:

- Full enclosure made of stainless steel

- Grinding wheel guard

- 4 grinding wheel flanges

- Pneumatic workpiece clamping

- Belt filtration unit

- Infinitely variable grinding spindle speed control

- Automatic central lubrication

- SP support with ball bearing for RMS from Ø 250 - 500 mm

- Automatic swiveling of the workpiece spindle as an NC axis, integrated into all automatic programs

Software packages:

- Grinding program for cup and peripheral wheels

- Grinding program for two wheels on one holder

- Grinding program for slot knife bushings

- Operating mode manual: manual movement of all axes

- Operating mode semi-automatic: axes move to preselected positions, electronic handwheel is enabled

- Operating mode fully automatic: automatic program sequence

Workpiece diameter: max. 500 mm

Grinding accuracy: ± 0.005 mm

Grinding spindle motor power: 7.5 kW

Speed: up to 6,000 rpm

Travel: 400 mm

Grinding wheel diameter: max. 200 mm

Grinding wheel bore diameter: 76.2 mm

Workpiece spindle motor power: 2.2 kW

Workpiece spindle speed: up to 300 rpm

Swivel range: 360°

Coolant pump: 100 l/min

Tank capacity: 375 l

Isdpex Ih Raofx Abketr

Connected load approx.: 12 kW (400 V / 50 Hz)

Dimensions (W x D x H): 4,300 x 3,000 x 2,300 mm

Weight approx.: 2,600 kg

Color: light grey / blue.

Mažas skelbimas

Wasbek

Wasbek

907 km

Konvencinė tekinimo staklė - Basic 180 V

KnuthBasic 180 V

Skambinti

Sąlyga: naujas, The Basic 180 V is a high-quality conventional lathe from the category of mechanic’s lathes, renowned for its robust construction. Featuring a bed width of 206 mm and an overall weight increased by 30 percent, this machine delivers outstanding machining quality suitable for heavy-duty cutting operations. Precision-ground and induction-hardened guideways ensure maximum manufacturing accuracy, while the powerful inverter drives the main spindle up to 3,000 revolutions per minute. The constant cutting speed enables facing operations with a surface finish comparable to CNC lathes. The comprehensive standard equipment includes a 3-axis position display, a coolant system, and a wide range of accessories, enabling flexible operation. If you are interested in the Basic 180 V, you can now order online and take advantage of the benefits this conventional lathe offers within the field of mechanic’s lathes.

Itsdpfouzlbuox Abksr

Mažas skelbimas

Burgoberbach

Burgoberbach

1 118 km

Paviršiaus šlifavimo mašina

DanobatRT-1600

Skambinti

Sąlyga: geras (naudotas), Gamybos metai: 1990, Funkcionalumas: visiškai funkcionalus, For sale: Surface grinding machine, brand Danobat, model RT 1600.

Particularly noteworthy are the size and travel distances of this machine. It is fully functional and immediately ready for use.

Technical data:

Year of manufacture: 1990

Power: 30 kW

Grinding length with magnetic chuck: 1610 x 710 mm

Longitudinal feed X-axis (automatic): 1700 mm

Cross feed Y-axis (automatic): 700 mm

Vertical feed Z-axis (automatic): 600 mm

Max. grinding wheel diameter: 450 x 203

Grinding spindle speed: 960 rpm

Motor power: 20 HP

Weight: 10,000 kg

Dimensions: 5500 x 2300 x 3100 mm

Included in the offer:

Goimendi S.A. band filter

Automatic wheel dresser

Transport and loading can be organized Europe-wide on request, at additional cost.

Prices plus VAT.

Viewing by appointment possible. Contact us—our team looks forward to assisting you.

Trade-in or exchange possible!

Isdpsuu Aiuofx Abkstr

Machinery Purchase / Sale

BUYING / SELLING PRODUCTION & METALWORKING MACHINES AND MORE

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you want to sell yours?

For further information or to contact us, please visit our website.

Mažas skelbimas

Vokietija

Vokietija

6 514 km

Grupinio gręžimo staklės

WMW FRITZ HECKERTBKR 32 x 4 AI

Skambinti

Sąlyga: naudotas, Techninės detalės:

Velenų skaičius: 1000

Gręžimo galia pliene (skersmuo): 32 mm

Gręžimo eiga: 200 mm

Apsisukimų diapazonas: 63 - 1000 aps./min

Gręžimo galia ketuje: 50 mm

Gręžimo veleno Morse kūgis: MK4

Veleno išsikišimas: 315 mm

Velenų atstumas: 475 mm

Gręžimo stočių skaičius: 3

Veleno galvutės pastūmos eiga: 280 mm

Padavimas: 0,08 - 1,25 mm/aps. (9 žingsniai)

Atstumas tarp veleno ir stalo: 710 mm

Stalo paviršius: 450 x 560 mm

Bendras galios poreikis: 12,4 kW

Mašinos svoris: apie 3,1 t

Mašinos matmenys (Ilg.xPlot.xAukšt.): apie 2,15 x 1,40 x 2,65 m

Itedpfsw Th Nlex Abkor

Ankstesnis savininkas iš nuoseklios gręžimo staklių pašalino veleną su dėže!

Mažas skelbimas

Gütersloh

Gütersloh

1 085 km

Rankenų gręžimo ir frezavimo staklės Elumatec GF 171

ElumatecGF 171

Skambinti

Sąlyga: naudotas, Gamybos metai: 2002, Rankenėlių alyvuogių gręžimo agregatas su trijų velenų gręžimo galva ir automatiniu pastūma leidžia dirbti dviem plokštumomis be medžiagos perkabinimo. Agregatas reguliuojamas pagal aukštį.

Iodex If Ayepfx Abkstr

Sūkių dažnis: 12 000 aps./min.

Pneumatinis medžiagos spaudimas

Minimalios dozės purškimo įrenginys

Frezavimo sritis horizontaliai pagal atramą: 300 x 120 mm

Profilio spaudimo sritis su gręžimo agregatu eiga 150 x 110 mm iki 400 mm reguliuojama

Eiga: 105 mm

Svoris: apie 200 kg

Mažas skelbimas

Więcbork

Więcbork

463 km

Plačios obliavimo staklės

V-HOLD lidermac reignmacVH-M 521

Skambinti

Sąlyga: naujas, Gamybos metai: 2021, V-hold czterostronna strugarka pięciowrzecionowa, model VH-M 521

- szerokość obrabianego materiału od 20 do 210 mm

- wysokość obrabianego materiału od 8 do 160 mm

1. wrzeciono od dołu – 7,5 kW

2. wrzeciono z prawej – 7,5 kW

3. wrzeciono z lewej – 7,5 kW

4. wrzeciono od góry – 11 kW

Ijdpfx Abehq Rp Hokotr

5. wrzeciono od dołu – 7,5 kW

- posuw 5,5 kW, zakres od 6 do 36 m/min

- obroty 6500 obr./min

- średnica wrzecion 40 mm

- posuw dla krótkich elementów, naprzeciwko wrzeciona prawego

- docisk przed i za wrzecionem górnym

- ręczna pompka do smarowania stołu

- masa maszyny 3100 kg

Dostępna od ręki

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Hlavní město Praha

Hlavní město Praha

848 km

Paviršiaus šlifavimo staklės

ChevalierFSG 1632 AD III

Skambinti

Sąlyga: naudotas, Gamybos metai: 2018, Funkcionalumas: visiškai funkcionalus, STALO DYDIS 400 x 800 mm

MAKSIMALUS ŠLIFAVIMO ILGIS 810 mm

MAKSIMALUS ŠLIFAVIMO PLOTIS 405 mm

MAKSIMALUS VERTIKALUS ATSTUMAS 620 mm (nuo stalo paviršiaus iki veleno ašies centro)

ILGINIS EIGA 850 mm (hidraulinė) / 900 mm (rankinė)

ILGINIO PADAVIMO GREITIS 5–25 m/min

GREITASIS EIGOS GREITIS

apie 60 Hz / 12 fpm (3,5 m/min), 50 Hz / 10 fpm (2,9 m/min)

AUTOMATINĖ ILGINIO EIGOS PRIDĖTIS 3–32 mm

AUTOMATINIS SKERSINIS PAVYZDAVIMAS 405 mm

RANKINIS SKERSINIS PAVYZDAVIMAS 460 mm

RANKENĖLĖS APSUKA 6 mm

Itodpox H S I Hsfx Abkor

RANKENĖLĖS PADALINIMAS 0,1 mm

MIKROPADAVIMO PADALINIMAS 0,001 mm

VERTIKALUS RANKINIS ĮSUKIMAS 0,01–0,04 mm

VERTIKALIOJI GREITOJI EIGA apie 500 mm/min

STANDARTINIO ŠLIFAVIMO RATAS DIAMETRAS 355 mm

PLOTIS 50 mm

KIAURYME 127 mm

HIDRAULINĖ SISTEMA 2 AG/6P

SKERSINIS PADAVIMAS 1/6 AG/4P

KĖLIMO PAVARA AC SERVO 1 kW

STAKLIŲ PLOTO UŽIMTIS 3340 x 1730 x 2080 mm

SVORIS 2900 kg

Mažas skelbimas

Wasbek

Wasbek

907 km

Konvencijinė tekinimo staklė - V-Turn 410 PROKonvencinė virpa - V-Turn 410 PROKonvencinė tekinimo st

KnuthV-Turn 410 PRO

Skambinti

Sąlyga: naujas, The V-Turn 410 PRO is a premium conventional lathe from KNUTH’s universal lathe product group, featuring the newly designed PRO model. It combines enhanced ergonomics and safety with a powerful inverter, supporting a high-performance spindle motor that reaches up to 3,000 rpm. This enables efficient machining of small-diameter workpieces as well as reliable performance for heavier cutting operations. Highlights include constant cutting speed, which automatically adjusts to the workpiece diameter, allowing you to achieve results comparable to CNC machines. The robust, solid cast-iron base and high-precision, preloaded spindle bearings ensure excellent concentricity and long-lasting operational quality. Further complemented by a comprehensive set of features, including a 3-axis position display (X.Pos) and a low-maintenance electromagnetic brake, the V-Turn 410 PRO is an ideal choice for demanding machining applications. Contact us for a quote on the V-Turn 410 PRO from the conventional lathe category and universal lathe product range.

Itodpfjww T S Ijx Abkor

Mažas skelbimas

Schwanberg

Schwanberg

1 115 km

Balandis uodega sąnarių mašina

OMEC650 M

Skambinti

Sąlyga: naujas, The manual milling machine Omec 650-M is suitable for producing dovetails on drawers and all types of furniture components. The machine is equipped with a spindle that features a milling cutter, allowing the creation of dovetails at various heights. The machine can produce four types of dovetails with different pitches.

The workpieces are clamped and released manually via eccentric shafts. Operation (ON / OFF) is controlled via an overload relay on the motor’s terminal board and handwheels with levers mounted on the sides of the machine. The machine is manufactured according to CE standards.

Technical data:

- Power requirement: 0.75 kW, 400 V, 50 Hz

- Number of spindles: 1

- Spindle speed: 16,500 rpm

- Standard dovetail pitch: 25 / 40 / 50 / 60 mm

- Machine weight: 100 kg

- Required floor space (L × W × H): 450 × 540 × 1420 mm

Workpiece dimensions:

- Workpiece length: 200 – 1500 mm

- Workpiece width: 60 – 280 mm

- Dovetail height: 5 – 18 mm

- Workpiece thickness: 7 – 45 mm

The machine comes as standard with the following equipment:

Itedpodcdwbjfx Abker

- Eccentric HSS milling cutter mounted on the machine

- Set of tools for adjustment and maintenance

- Operating manual.

Mažas skelbimas

Vokietija

Vokietija

6 514 km

Diskinis pjūklas

BEHRINGER-EISELEPSU 450 H

Skambinti

Gamybos metai: 2007, Sąlyga: naudotas, Technical details:

Saw blade diameter: Ø 400 - 450 mm

Saw blade bore: Ø 50 mm

Spindle speeds: 6 / 12 / 24 / 48 (2-step) rpm

Motor speeds: 1400 / 2800 rpm

Cutting capacity at 90 degrees, round: Ø 150 mm

Cutting capacity at 90 degrees, square: 140 x 140 mm

Cutting capacity at 90 degrees, flat: 400x30 / 345x70 / 300x95 mm

Table size: Ø 700 mm

Rotatable table: 360°

Compressed air connection: 6 - 8 bar

Total power requirement: 3.6 kW

Machine weight approx.: 1900 kg

Machine dimensions: D: 1.5 x W: 1.0 x H: 2.35 m

CIRCULAR SAW SEMI-AUTOMATIC - PROFILE CIRCULAR SAW MACHINE - UNDERFLOOR SAW

Profile circular saw with two-hand operation

Suitable for cutting materials such as solid steel, pipes, and profiles within the specified cutting ranges.

Cutting speed depends on the material to be cut

Mitre angles: 30° - 45° - 90°

Saw blade feed rate adjustable

Itedou Nimqjpfx Abksr

Operating pressure / Clamping pressure: 50 bar / 30 bar adjustable

Hydraulic pump: 2.2 kW

Coolant system with pump

Minimal quantity lubrication

Piece counter

Operation via control panel / two-hand operation

Palengviname jums paiešką: "evolution"

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota Evolution (778)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- Agie Evolution

- Agie Evolution 2

- Ctx

- Deckel Maho

- Deckel Maho Dmu 70 Evolution

- Elektriniai Metalo Žirklės

- Holzher Evolution

- Holzher Evolution 7405

- Keturpusės Obliavimo Obliavimo

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo