Šildymas Mediena pirkti naudotą (14 391)

Wiefelstede

Wiefelstede Medienos freza

unbekanntØ 160 mm

Wiefelstede

Wiefelstede Šildymo elementas

Siemens2NW 3510 J100 519 201

Wiefelstede

Wiefelstede Šildymo elementas

unbekannt825/100/H130 mm

+44 20 806 810 84

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ130 x 110 mm 2500 W

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ200 x 195 mm 4640 W

Atraskite daugiau naudotų mašinų

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ150 x 160 mm 2450 W

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

SynventiveØ32 x 265 mm

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ100 x 22 mm 400 W

Wiefelstede

Wiefelstede Salės šildymas 30 kW elektrinis

Eltra1BGL1CE04001

Wiefelstede

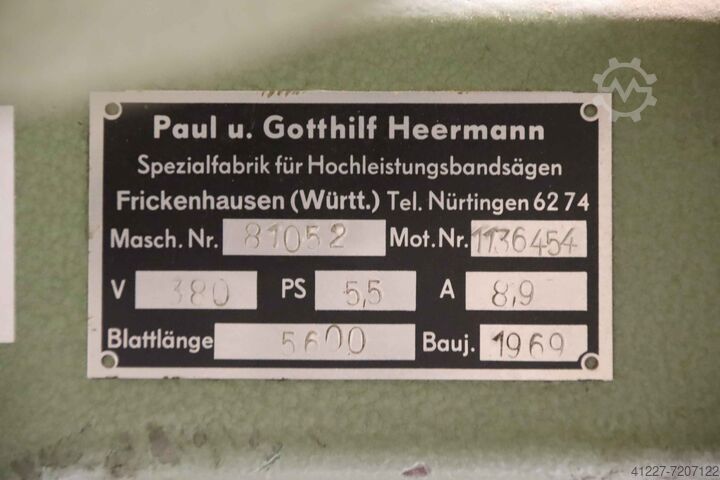

Wiefelstede Medienos juostinis pjūklas 4 kW

HemaArbeitstisch schwenkbar

Wiefelstede

Wiefelstede Medienos freza

LeitzDufix

Wiefelstede

Wiefelstede Šildymo bakas kraštų klijavimo staklėms

Homag

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ x 20 mm 215 W

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ200 x 185 mm 5640 W

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ120 x 44 mm 750 W

Wiefelstede

Wiefelstede Medienos frezavimo staklių greito suspaudimo sistema

LEUCOAufnahme 35 mm

Wiefelstede

Wiefelstede Elektrinis šildymo registras

Helios**EHR-R 6/315

Wiefelstede

Wiefelstede Salės šildymas 53,5/64,9 kW

KampmannTip 5000 2-Stufen 157000573036

Wiefelstede

Wiefelstede Būgno šildymas

unbekannt1082 105 BHT 932 07/20

Wiefelstede

Wiefelstede Šildymo elementas

Hilzinger9000W 230/400V

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

KraussMaffeiØ200 x 160 mm 5500 W

Wiefelstede

Wiefelstede Šildymo juosta Šildymo rankovė

ErgeØ150 x 145 mm 2400 W

Wiefelstede

Wiefelstede Šildymo bakas kraštų klijavimo staklėms

IMA7x 800 Watt

Wiefelstede

Wiefelstede šildymo žarna

FematechFE-N-2.4-8-1U120

Wiefelstede

Wiefelstede Kampinė pavara šildymo baseinams

Homag1-005-16-0000 D

Naudota Šildymas Mediena (14 391)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

+44 20 806 810 84