Apdirbimo centrai su lygiuoju arba rastro stalu pirkti naudotą (347)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Medienos apdirbimo staklės CNC apdirbimo centrai medienai Apdirbimo centrai su lygiuoju arba rastro stalu

Mažas skelbimas

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

1 325 km

Biesse Rover 20

BiesseRover 20

Skambinti

Sąlyga: labai geros būklės (naudotas), Galimybė iš Šveicarijos likvidacijos puikios būklės

Ljdpfx Asxhg Etef Iohb

Mažas skelbimas

Šveicarija

Šveicarija

1 266 km

IMA BIMA 310 120/300

IMABIMA 310 120/300

Skambinti

Sąlyga: paruoštas naudoti (naudotas), Gamybos metai: 1999, X ašies eiga: 3 000 mm, Y ašies eiga: 1 000 mm, valdiklių gamintojas: SIEMENS, bendras svoris: 5 000 kg, veleno greitis (maks.): 9 000 aps./min, ašies variklio galia: 12 000 W, ašių skaičius: 3, Papildoma įranga

• 1 vertikalus gręžimo įrenginys Y kryptimi

• 1 vertikalus gręžimo įrenginys X kryptimi

• 1 pagrindinis velenas su programuojama sukimosi kryptimi

• 1 centralizuotai integruota CNC ašis, besisukanti 360 laipsnių kampu

• 1 adapterio pjūklas, pritvirtintas 90 laipsnių kampu

• Pjūklo disko skersmuo: 200 mm

• 1 adapterio blokas, horizontali gręžimo ir frezavimo galvutė (kryžminė galvutė)

• 1 adapterio bloko horizontalioji freza (priešinis frezavimas)

Lhedpfx Ajx N Ulmef Ieb

• 2x adapteriai vyriams gręžti

• Yra 1 naujas Siemens vakuuminis siurblys + daug priedų

Mašinos privalumai

Techninės mašinos privalumai

• Maks. Priveržimo aukštis nuo viršutinio siurbimo plokštės krašto: z1 100 mm

• Darbinis aukštis: 950 mm

• Kelio veikimo greitis: 20 m/min

• Pagreitis: 5 m/s²

• Lauko ploto keitimas be švytuoklinio apdirbimo: x 2 x 1400 mm

• Laisva erdvė viduryje: x 200 mm

• Su švytuokliniu apdirbimu: x 2 x 900 mm

• Laisva erdvė viduryje: x 1200 mm

• Įrankio padavimas: automatinis

• Tiekimo jėga: 11000 n

Papildoma informacija

Medijos ištraukimo standartas: jungtis 200 mm, 120 mm ir 100 mm skersmens Ištraukimo greitis: apytiksl. 28 m/sek. Ištraukimo tūris: apytiksl. 3200 m³ per valandą 1 vakuuminis siurblys 40 m³/h Suslėgtas oras: Centrinė jungtis 1/2" su priežiūros įrenginiu. Oro slėgis 6 bar pastovus Elektros įranga Elektros instaliacija pagal EN Valdymo spintos matmenys (AxPxG): 2000 mm / 1200 mm / 600 mm Saugos ir apsaugos priemonės pagal CE

Mažas skelbimas

Scerne

Scerne

1 566 km

Dvigubo stalo apdirbimo centras

BIESSEExcel TT

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2018, Funkcionalumas: visiškai funkcionalus, Double table machining center

Working area X: 2,590 mm

Working area Y: 2,260 mm

Working area Z: 400 mm

Number of milling spindles: 2

Spindle with liquid cooling

Main motor: 19.2 kW

Max spindle speed: 24,000 rpm

Aggregate heads

4th axis: C-Axis

Tool clamping system: HSK-F63

Central tool changer magazine: 24 positions

Tool changer on each head: 12 positions

Vertical drilling heads: 20 (per head)

Horizontal drilling bits X: 8

Horizontal drilling bits Y: 8

Grooving saw in X and Y directions

2 tables

Number of vacuum pumps: 4, each 360 m³/h

T-Jet chip blowing system

Nesting

Manual labeling

Barcode reader

Tool length measurement

Software: BIESSE BIESSEWORKS ADVANCED, BIESSE B_NEST

Lhedpfsuqw E Njx Af Ieb

Weight: 17,900 kg

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

San Giovanni Al Natisone

San Giovanni Al Natisone

1 262 km

2000 SAOM T55 CNC pantografas naudotas, nepatikrintas, parduodamas tokios būklės, kokioje yra.

SaomT55

Skambinti

Sąlyga: naudotas, Gamybos metai: 2000, 2000 SAOM T55 CNC pantografas naudotas, nepatikrintas, parduodamas tokios būklės, kokioje yra.

Lhjdpfxex Ttxge Af Ijb

Mažas skelbimas

Almelo

Almelo

1 174 km

Apdirbimo centras

CNC-ROUTER DMA-BudgeCraftNesting Professional

Skambinti

Sąlyga: paruoštas naudoti (naudotas), Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, X ašies eiga: 2 600 mm, Y ašies eiga: 1 300 mm, Z ašies eigos atstumas: 200 mm, greitas poslinkis X ašimi: 50 m/min, greitas poslinkis Y ašis: 50 m/min, greitasis eiga Z ašyje: 15 m/min, Įranga: dokumentacija / vadovas, drožlių transporteris, sūkių greitis be galo kintamas, - BudgeCraft CNC ROUTER

- Best Price-Quality CNC

- CNC Router: Wood, Plastic & Aluminium Processing

- High Precision (0.01mm) Milling

- No Annual License Fees

Descriptions:

The most comprehensive CNC machine for wood, plastic, and aluminium. Fully servo-driven for even the most complex operations. Starting from €34,500.

- Benefit from a fixed-price CadCam software package and starter kit.

- Assembled in the Netherlands to the strictest CE standards.

- Powerful 9kW ATC spindle and speeds up to 50m/min.

- Equipped with automatic tool changer magazine for up to 16 tools.

- From standard milling tasks to complex projects.

- BudgeCraft offers the highest precision and lowest purchase price for professionals.

Highlights:

* No hidden license fees

* CadCam Professional supports image file input: BMP, JPG, TIF, GIF, PNG vector files

* Format support: Adobe Illustrator, DXF (AutoCAD), EPS, PLT, TXT

* 9kW ATC spindle, air-cooled

* Ready for immediate operation

CNC ROUTER:

Specifications Precision CNC-ROUTER: View the technical details of our 0.01mm precision.

Work Areas & Options: From 1300x2600, 1600x3200, to 2100x3200mm.

CE Safety: Why our machines are the safest choice in your workshop. Compliant with New Machinery Directives 2026.

Full Technical Specifications overview on the Danmar Machines Bv website:

Work area X-axis: 2600, 3200mm

Lhedsx Sx Rfspfx Af Ieb

Work area Y-axis: 1300-1600-2100mm

Z-axis stroke: 200mm

Gantry construction: Yes, with servomotors

Milling motor: 9kW Servomotor (ATC spindle)

Speed: 1,000–24,000 rpm

X-Axis travel: 50m/min

Y-Axis travel: 50m/min

Z-Axis travel: 15m/min

Tool holder: ISO30-ER32-ER40

Software: Pegasus PWoodMilling

Vacuum pump: included

Contact us for more information.

Mažas skelbimas

Willroth

Willroth

1 209 km

Apdirbimo centras

MORBIDELLIM 600 F

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2013, veikimo valandos: 16 750 h, Funkcionalumas: visiškai funkcionalus, Naudota MORBIDELLI M600 F

Lsdsx S Ha Iepfx Af Ijhb

- pilna nestavimo ląstelė

- Gamybos metai: 2013

- Gera būklė, visiškai veikianti

- Darbinė zona x=5000 / y=2120

- 5 ašių freza

- Gręžimo galva

- 2 vakuuminiai siurbliai

- Automatinis pakrovimas ir išvežimo transporterio juosta

- Prieinama pagal susitarimą

- (be įrankių)

Dėl papildomos informacijos kreipkitės į mus.

Mažas skelbimas

Bitburg

Bitburg

1 305 km

Apdirbimo centras / lizdo mašina

Holzfräse BesslerAxolox

Skambinti

Sąlyga: beveik kaip naujas (parodų įrenginys), Gamybos metai: 2024, CNC Wood Router Axolox 3021 – Demo Unit Immediately Available –

Manufactured from 19mm Forescolour, comprising a router table (X-axis), gantry (Y-axis), Z-axis unit in compact panel, and base frame with adjustable machine feet. The router bed serves as a sacrificial plate in 19mm MDF. Table openings are preconfigured longitudinally and transversally. Mechanical set includes profile guides with profile guide carriages, ball screws, and precision rack and pinion drives. All components are installed, pre-lubricated, test-run and instantly operational. Control set includes control cables, drag chains, planetary gearboxes, stepper motors, high-performance power amplifiers, power supply unit, and toroidal transformer, all fully pre-assembled in the control cabinet, as well as sensors on each axis. Switch relays for automatic operation of existing extraction system. Brush seals as dust protection, and safety devices compliant with CE through a mobile extraction device and a side-mounted laser scanner for work area monitoring, featuring a 275° and 5.5 m field of view (suitable for corner placement). Handheld control panel equipped with all essential machine operation functions, including emergency stop and dead man’s switch. Tool length sensor for determining tool length and adjusting the active zero offset. High-frequency spindle with 2.2 kW, including clamping nut, frequency converter, mains filter, brake resistor, and collet set. Monitor as built-in display, including mini PC with Windows 10, with Beamicon2 control software as well as mouse and keyboard, pre-installed in an ergonomic console. CAD license Rhino 7.0 and CAM license Estlcam V11, as well as all necessary documentation, will be emailed prior to delivery.

- Router bed engineered as vacuum table, comprising six individually controllable segments. Cross table made of PE with MDF deck plate. Becker brand vacuum pump, rated at 160 m³/h, oil-lubricated. The vacuum pump requires a 16-amp, 400 V AC plug for power supply. Customer provides HDF, 3mm raw both sides, for the entire vacuum table surface (3000x2100mm), to use as a sacrificial plate. (Recommended application: machining coated chipboard materials)

Lhsdpfxowdny Ts Af Ijb

- Tool set: 10 pieces

2 pcs. 5 mm TAC double-flute cutters.

8 pcs. 4 mm solid carbide single-flute cutters.

- Maintenance package:

includes 150 ml grease gun, one 400 g cartridge of high-performance grease, 500 ml can of silicone spray grease, one lubrication nipple

- Hold-down clamp

as an adapter for the existing high-frequency spindle. Ideal for slightly curved and particularly thin materials

Location: Ex-stock 54634 Bitburg

– Immediately available –

Offer subject to prior sale.

Mažas skelbimas

Bitburg

Bitburg

1 305 km

Apdirbimo centras su 1300 mm pločiu

GannomatProtec 0571A132B

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2020, MACHINING CENTER

GANNOMAT "PROTEC 0571" Working Width 1300

Drilling, Grooving, Milling

Base machine complete in standard version as per price list 01/19/D:

For detailed technical data, see PROTEC Type 0571 data sheet

-

Processing unit with:

PowerBlock with 21 spindles and 1 grooving saw (BK 1341)

- 13 vertical drilling spindles

- 6 horizontal drilling spindles in Y axis

- 2 horizontal drilling spindles in X axis

- 1 grooving unit in Y axis

4th drilling axis in Y

-

Milling unit Profit F3 HSK63F with 3-position magazine for automatic tool change, 5.5 kW motor (S1), 1000-20000 rpm with frequency converter, right and left rotation, HSK63F tool holder with 462E collet, milling cutter length up to 130 mm.

-

INCLUDING OPTION:

Additional safety device with lamella curtain for processing Lamello P-System. Required for horizontal milling for Lamello P-System with slot cutter Ø 100.4 x 7 x 30 mm.

-

Workpiece sizes and weights:

Lsdpfx Asw Sguwjf Iohb

- Workpiece width (X): min. 60 mm / max. 1300 mm

- Workpiece thickness (Z): min. 6 mm / max. 60 mm

- Workpiece length (Y): min. 263 mm in throughfeed mode, max. 5600 mm programmable workpiece length in software

- Workpiece weight: max. 75 kg.

-

Air supply: 7 bar

Machine No. 435.046

Electrical connection: (400V, 3Ph, 50Hz, (12kVA, 17.5A)

- Top pressure device for working width 1300 mm

- Roller table 765 mm (Y axis), foldable, for machine front, B 500 mm

- Roller table 765 mm (Y axis), foldable, for machine rear, B 500 mm

- Auxiliary stop 600 mm with integrated rollers for roller tables

- Extraction manifold Ø 160 mm / Ø 80-80-80 mm, spacing 196 mm

- Documentation in German:

Operating instructions: GERMAN

Programming instructions: GERMAN

Operator software: GERMAN

Operating system: ENGLISH

Keyboard: GERMAN

Location: ex stock 54634 Bitburg

- immediately available -

Mažas skelbimas

Leipzig

Leipzig

875 km

Apdirbimo centras

FORMAT-4profit H10 22.43

Skambinti

Sąlyga: naudotas, Gamybos metai: 2017, veikimo valandos: 1 800 h, No. 3131

CNC Machining Center FORMAT-4 profit H10 22.43

Lsdpfx Aorrh T Aef Ijhb

Used, year of manufacture: 2017

Operating hours: approx. 1,800 h

Package consisting of CNC machining center FORMAT-4 profit H10 22.43, loading unit FORMAT-4 L-Motion, and extraction system FELDER RL 300

Technical Data – CNC Machining Center FORMAT-4 profit H10 22.43:

- Matrix table system made of phenolic resin

- Grid table with two stop rows

- Automatic central lubrication

- HARDWARE control computer

- Mobile control console

- Handheld terminal for remote axis control

- Two vacuum pumps, rated output 2 x 250 m³/h

- Tool changer with 10 tools

- Tool changer on the left in the machine frame: 8 tool positions for HSK

- Milling spindle 12 kW (S6) HSK F63, 24,000 rpm

- Central extraction via combined connections (D = 250 mm)

- Woodflash software German version (H20/H08/H10/H50)

- Axis travel path H10 22.43: X = 5,230 mm / Y = 2,560 mm / Z = 280 mm

- Working area: X = 4,300 mm / Y = 2,160 mm / Z = 105 mm

- Axis positioning speed: X = 100 m/min / Y = 100 m/min / Z = 30 m/min

Technical Data – Loading Unit FORMAT-4 L-Motion:

- Year of manufacture: 2017

- 2-axis design with 4 storage positions for feeding a H10 with lift table

- CNC loading

- Gentle transport

- Fully automatic panel handling

- Workpiece sizes: Length 2,000–4,200 mm / Width 600–2,100 mm / Thickness from 8 mm / Panel weight 200 kg

- Density: Chipboard 650 kg/m³ / Raw MDF 750 kg/m³

- Stack height 1,800 mm

Technical Data – Extraction System FELDER RL 300:

- Year of manufacture: 2023

- Rated volume flow 6,000 m³/h, H3 GS dust-tested, JET cleaning

- Compressed air connection 3/4-inch

- Connection pressure 7–12 bar at 40 NL/min

- Operating pressure in device: 6 bar

- Chip container capacity: 500 l

- Extinguishing device with dry powder extinguisher 12 kg

Sale on behalf of customer, ex location Leipzig, without dismantling, without transport or installation

Subject to errors in description and price

Dismantling and loading by us available as an option

To avoid misunderstandings, on-site inspection by appointment is possible and recommended

Sale in as-is condition

Technical specifications, condition descriptions, year of manufacture, and scope of delivery according to manufacturer's brochure or previous owner, without guarantee

Subject to prior sale

For used machines, any warranty is excluded; the following applies: “sold as inspected”

Images and videos are sample representations and do not reflect the actual scope of delivery

Terms of payment: Prices plus statutory VAT, payment before collection or shipping

Delivery terms: ex works

Aukcionas

Aukcionas pasibaigęs

Kranj

Kranj

1 192 km

5 ašių apdirbimo centras

SCMRECORD 132 Prisma

Sąlyga: paruoštas naudoti (naudotas), Gamybos metai: 2006, veikimo valandos: 19 857 h, Funkcionalumas: visiškai funkcionalus, X ašies eiga: 4 400 mm, Y ašies eiga: 1 300 mm, Z ašies eigos atstumas: 180 mm, įrankių magazino lizdų skaičius: 72, TECHNINĖS DETALĖS

X ašies eiga: 4 400 mm

Y ašies eiga: 1 300 mm

Z ašies eiga: 180 mm

Frezavimo mazgo galia: 15 AG

Įrankių keitimas: automatinis

Įrankių vietų skaičius: 3 x 24 lizdai

ĮRANGA

Lhodpjx Sri Ijfx Af Iob

Darbo stalas su skersine sija

Pagalbinis įrenginys sunkioms detalėms

Pneumatiniai spaustuvai durų ir langų gamybai

Vakuuminis siurblys 250 m3/h

Automatinis tepimas

Atliekų transporteris

Mažas skelbimas

Plattling

Plattling

1 035 km

CNC lizdavimo staklės

HOMAGCENTATEQ N-800

Skambinti

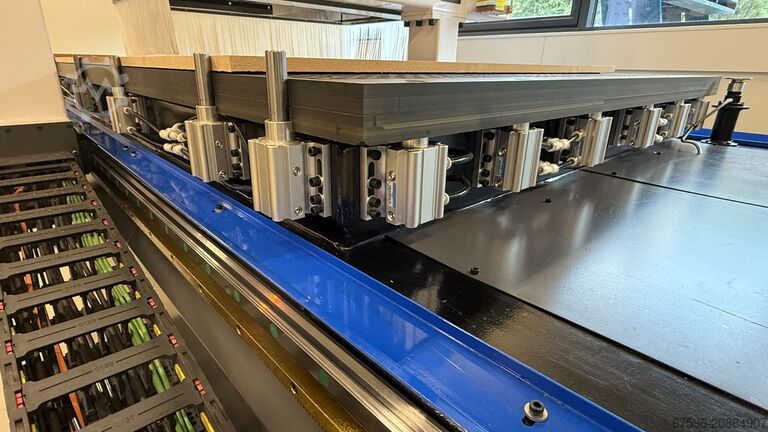

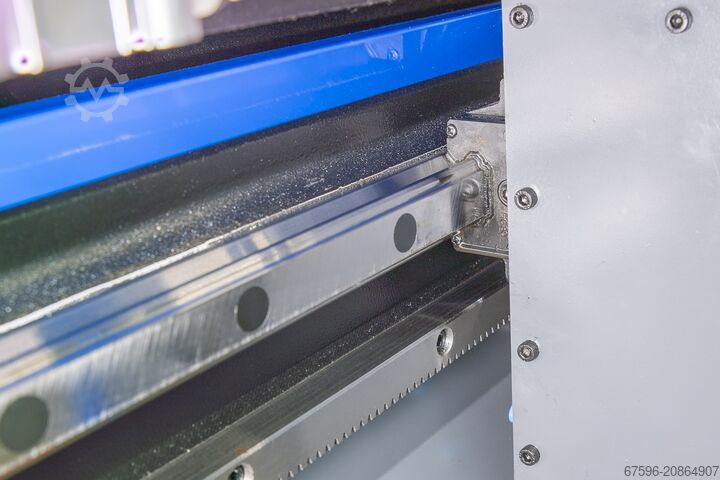

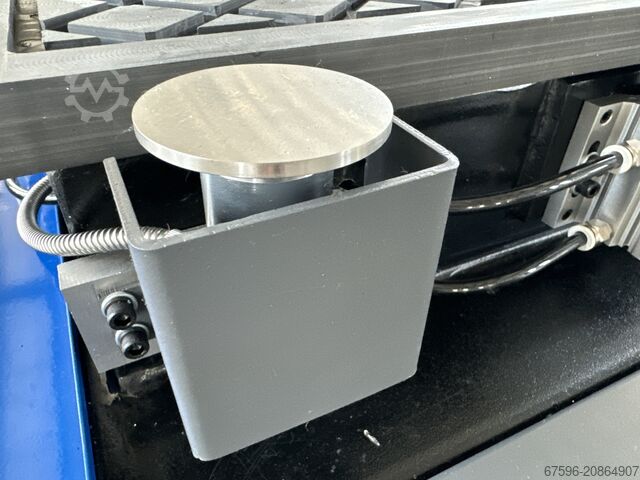

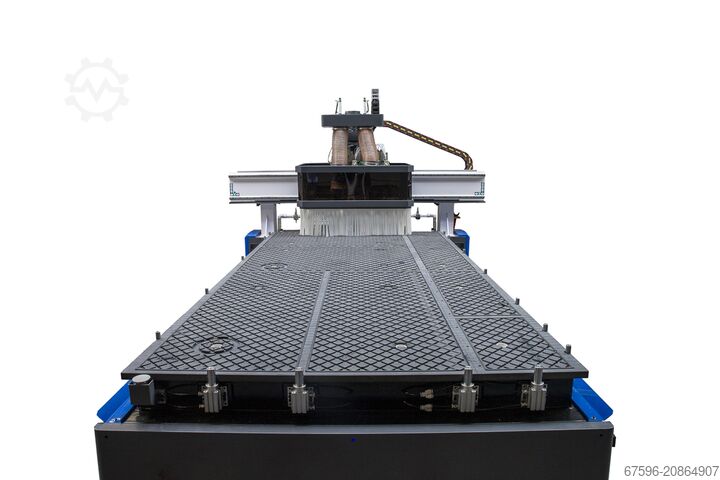

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2019, Funkcionalumas: visiškai funkcionalus, mašinos/transporto priemonės numeris: 0-250-84-4817, X ašies eiga: 4 300 mm, Y ašies eiga: 2 250 mm, Z ašies eigos atstumas: 400 mm, valdiklių gamintojas: HOMATIC, valdiklio modelis: PC86 PowerControl, ruošinio ilgis (maks.): 4 300 mm, ruošinio plotis (maks.): 2 250 mm, bendras aukštis: 2 800 mm, stalo plotis: 2 250 mm, stalo ilgis: 4 300 mm, ašies variklio galia: 12 000 W, įėjimo įtampa: 400 V, įvesties srovės tipas: trifazis, Įranga: dokumentacija / vadovas, HOMAG CENTATEQ N-800, BHP 210/43/22/R

4-axis CNC machine

Year of manufacture: 2019

Operating hours: 7,840 h main operation / 2,420 h secondary operation

Parts counter: 28,661

(as of 13.01.2026)

Maximum workpiece dimensions:

• X-axis: 4,300 mm

• Y-axis: 2,250 mm

• Z1-axis: 410 mm, Z2-axis: 185 mm

SPECIFICATION / CONFIGURATION

MATRIX-PRO machining table, size 4,300 x 2,250 mm

- 4 pneumatic, retractable stops with electronic position detection

- 3 vacuum pumps, each with a capacity of 290/345 m³/h at 50/60 Hz, total 870/1,035 m³/h

Ledjx Rcdajpfx Af Ishb

- 2 separable vacuum zones of 2,150 x 2,250 mm each

- 3 safety/anti-slip mats, safety fence with door

- Main spindle 11 kW, 24,000 rpm

- Liquid cooled

- Spindle with C-axis interface

- Tool holder/clamping HSK F63

- SENSO-FLEX probing system, controllable in Z-direction

- Vertical drilling unit with 21 spindles, drive power 2.3 kW

- 14-position tool changer (carousel)

1 ROLLER TABLE for panel handling 7,080 x 2,200 mm

Control / software:

- PowerControl PC86 powerTouch

- WoodWop 7.1

Machine dimensions:

11.60 x 4.50 x 2.80 m

The machine can still be inspected under power

Availability: from July 2026 (approx. week 28)

Mažas skelbimas

Lukovica

Lukovica

1 192 km

Apdirbimo centras

MorbidelliAuthor 444S

Skambinti

Sąlyga: geras (naudotas), Gamybos metai: 2007, Funkcionalumas: visiškai funkcionalus, X ašies eiga: 5 000 mm, Y ašies eiga: 1 700 mm, Z ašies eigos atstumas: 180 mm, greitas poslinkis X ašimi: 45 m/min, greitas poslinkis Y ašis: 45 m/min, greitasis eiga Z ašyje: 30 m/min, padavimo ilgis X ašis: 4 500 mm, padavimo eiga Y ašimi: 1 300 mm, padavimo ilgis Z ašis: 180 mm, X ašies padavimo greitis: 45 m/min, Y ašies padavimo greitis: 45 m/min, padavimo greitis Z ašis: 30 m/min, valdiklių gamintojas: esa, valdiklio modelis: kvara 6, ruošinio ilgis (maks.): 4 500 mm, ruošinio plotis (maks.): 1 300 mm, ruošinio aukštis (maks.): 180 mm, bendras aukštis: 2 750 mm, bendras ilgis: 7 000 mm, bendras plotis: 3 000 mm, stalo plotis: 1 200 mm, stalo aukštis: 950 mm, stalo ilgis: 4 500 mm, sukimosi greitis (min.): 24 000 aps./min, sukimosi greitis (maks.): 24 000 aps./min, bendras svoris: 5 000 kg, veleno greitis (min.): 24 000 aps./min, veleno greitis (maks.): 24 000 aps./min, ašies variklio galia: 7 500 W, ašies skaičius: 2, įrankių magazino lizdų skaičius: 10, tvirtinimo skersmuo: 200 mm, įrankio ilgis: 200 mm, įrankio skersmuo: 150 mm, įrankio svoris: 5 000 g, įėjimo įtampa: 400 V, Įranga: dokumentacija / vadovas, sūkių greitis be galo kintamas, Elektroninis valdymas su PC Office

Programinė įranga Xilog Plus

Nuotolinio valdymo įrenginys pagrindinėms mašinos funkcijoms valdyti

Darbinė zona: 4400 x 1300 x 180 mm

"Nesting" aliuminio darbinis stalas

Atbulinės eigos sistema

6 galiniai atmuštuvai

6 nuskandinti tarpiniai atmuštuvai, esantys 620 mm nuo galinės pusės

1 elektros velenas 7,5 kW – HSK 63

RAPID įrankių keitiklis 10 pozicijų

2 rankinio įrankių keitimo varikliai HSK63F

Diskinis mazgas 0–90°, 4 AG

Gręžimo blokas:

18 nepriklausomų vertikalių gręžtuvų

3 nepriklausomi horizontalūs gręžtuvai su dvigubomis išeigomis: 2 „X“ kryptimi ir 1 „Y“ kryptimi

2 vakuuminiai siurbliai po 250 m³/h

Automatinis tepimas

Optimizuota nusiurbimo sistema

Ljdpfxsufgg Rs Af Ishb

Apsauginiai tinklai ir buferis

CE ženklinimas

Mažas skelbimas

Estija

Estija

388 km

Apdirbimo centras

TeknaTKE783

Skambinti

Sąlyga: naudotas, Gamybos metai: 2015, Vertikalus CNC apdirbimo centras su 3 valdomomis ašimis ir išskirtine Y ašies apdirbimo talpa. Jame įrengta vakuuminių stalų tvirtinimo sistema, kuri laiko plokštes ir lakštus vakuumo pagalba. Šis sprendimas ypač veiksmingas apdirbant plonas detales, kurias sunku pritvirtinti naudojant įprastas spaustuvų sistemas.

Apdirbimo centras aprūpintas vožtuvų rinkiniu, leidžiančiu įjungti arba išjungti skirtingas stalo zonas, taip sutelkiant vakuumą tam tikroje srityje ir optimizuojant mažų komponentų tvirtinimą.

Galimybė atlikti interpoliuotą frezavimą ir gręžimą kompozitinėse plokštėse, aliuminio, plieno ar titano lakštuose bei aliuminio profiliuose.

Tekna tiekia patogią naudoti programinę įrangą, kurią gali valdyti tiek patyrę CNC programuotojai, tiek mažiau patirties turintys vartotojai.

TKE 783 – tai apdirbimo centras su 3 valdomomis ašimis, skirtas interpoliuotam gręžimui ir frezavimui kompozitinėse plokštėse, aliuminio, plieno ar titano lakštuose bei aliuminio profiliuose.

Lhedpfxsv D A Ime Af Ijb

Techninė specifikacija:

Modelis: Tekna TKE783

Pagaminimo metai: 2015

Galia: 29 kW

Apdirbimo stalo matmenys: 2010 x 6300 mm

Svoris: 4842 kg

Greitis: X ašis 70 m/min; Y ašis 55 m/min; Z ašis 30 m/min

Programinė įranga: Windows, Embedded, Teach-in software CAD/CAM 2D NC TOOL

Pagaminta: Italijoje

Kita: buvo dirbama su aliuminio frezavimu iki 4 mm.

Staklės prijunktos, galima pamatyti kaip veikia ir išbandyti Estijoje. Bus paruoštos transportavimui balandžio – gegužės mėnesį.

Jei turėsite papildomų klausimų, mielai atsakysime.

Mažas skelbimas

Almelo

Almelo

1 174 km

Apdirbimo centras

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, X ašies eiga: 2 600 mm, Y ašies eiga: 1 300 mm, Z ašies eigos atstumas: 200 mm, greitas poslinkis X ašimi: 40 m/min, greitas poslinkis Y ašis: 40 m/min, greitasis eiga Z ašyje: 15 m/min, ruošinio aukštis (maks.): 350 mm, bendras ilgis: 3 500 mm, bendras plotis: 2 100 mm, sukimosi greitis (min.): 1 000 aps./min, sukimosi greitis (maks.): 24 000 aps./min, bendras svoris: 2 460 kg, įėjimo įtampa: 400 V, Įranga: dokumentacija / vadovas, drožlių transporteris, sūkių greitis be galo kintamas, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new custom processing center for those who demand precision and reliability.

Designed and assembled in the Netherlands according to the strictest European standards.

This machine is built for small and medium-sized enterprises.

With a robust welded steel chassis, servo drive, automatic tool changer, and intelligent software integration, it is the ideal solution for everything from cabinetmaking to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Requires limited floor space

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Portal Milling

Ledsx R D Rnopfx Af Iehb

- Processes: wood, plastics, aluminum, acrylic, foam, plastic, etc.

- Unlimited possibilities

- No licenses required

- Pegasuds CAD/CAM software (see videos)

- 1-year online helpdesk support

CNC Machines: Fairly priced, for professionals who can handle it themselves.

Pay for steel, not for service. Our CNCs are for the savvy, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our rock-bottom price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without the overhead costs. For professionals with technical expertise.

Mažas skelbimas

Almelo

Almelo

1 174 km

Apdirbimo centras

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, X ašies eiga: 2 600 mm, Y ašies eiga: 1 300 mm, Z ašies eigos atstumas: 200 mm, greitas poslinkis X ašimi: 60 m/min, greitas poslinkis Y ašis: 60 m/min, greitasis eiga Z ašyje: 20 m/min, valdiklių gamintojas: syntec, ruošinio ilgis (maks.): 6 000 mm, ruošinio plotis (maks.): 2 100 mm, ruošinio aukštis (maks.): 350 mm, bendras aukštis: 2 200 mm, bendras ilgis: 4 200 mm, bendras plotis: 2 100 mm, stalo apkrova: 1 500 kg, sukimosi greitis (min.): 1 000 aps./min, sukimosi greitis (maks.): 24 000 aps./min, bendras svoris: 2 800 kg, veleno tvirtinimas: MK 3, įrankių magazino lizdų skaičius: 10, įėjimo įtampa: 400 V, įvesties srovės tipas: trifazis, Įranga: dokumentacija / vadovas, sūkių greitis be galo kintamas, Cost savings for the end customer: €80,000 instead of €40,000

DMA supplies high-quality CNC machines at unbeatable prices by eliminating costly service contracts and on-site installation visits. Ideal for professionals who want full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts delivery: In the event of a defect within 12 months, spare parts will be sent free of charge after diagnosis (photo/video). • Labor costs not included: You can replace the part yourself or hire an external service provider.

• Low-maintenance designs.

• Digital commissioning: via app or TeamViewer, direct online support. This eliminates the need for technician visits, saving both time and money.

Lhodex Rz Auspfx Af Ijb

• Online support: Available 24/7.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components instantly identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3200 x 1600 mm (standard dimensions available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW milling spindle.

Up to 26 spindle positions.

Line drilling unit optional. Groove milling cutter optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes with servo drive systems.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1300 x 2600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW milling spindle

Drilling unit optional

Groove milling cutter optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Mažas skelbimas

Almelo

Almelo

1 174 km

Apdirbimo centras

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at rock-bottom prices by foregoing expensive service contracts and installation visits. Ideal for professionals who want to stay in control themselves.

The purchase price includes:

- CNC controller "SYNTEC"

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools for sheet metal processing CNC machining center.

• Parts delivery: In case of a defect within 12 months, parts will be sent free of charge after diagnosis (photo/video).

• Labor not included: Replacement of the part is done by you or outsourced by you

• Designed for low maintenance

• Digital preparation: Direct online service via app or TeamViewer. This can eliminate the need for technician visits – saving costs and time

• Online service: 24/7

Lsdpfxsxx Uc Ue Af Ishb

Digital Support as an Alternative

• Video tutorials: clips on calibrating or replacing components

• Exploded view diagram: Instantly identify which part is involved

Focus on functionality: Your machine, your control, our lowest price.

You can call/WhatsApp us for more information and/or to make an appointment.

WhatsApp:

Mažas skelbimas

Pszczyna

Pszczyna

668 km

Apdirbimo centras

KimlaLF 1020 Powercut 2 kW

Skambinti

Sąlyga: naudotas, Gamybos metai: 2022, veikimo valandos: 814 h, Funkcionalumas: visiškai funkcionalus, nominali (akivaizdi) galia: 2 kVA, Kimla LF 1020 Powercut 2 kW Fiber Laser – Precision and Efficiency for Your Production

The Kimla LF 1020 Powercut fiber laser cutting machine, equipped with a 2 kW fiber resonator, is a technologically advanced solution designed for companies seeking maximum efficiency, precision, and reliability in metal processing. As a product of a renowned Polish manufacturer, this machine combines innovative engineering with solid construction, ensuring a competitive edge in a dynamic market.

The LF 1020 model has been optimized for processing sheet metal of standard sizes, offering a working area of 1000 x 2000 mm. This makes it a versatile tool suited to a wide range of applications—from single-piece to series production.

Key Features and Benefits:

• Dynamic Linear Drives: Unlike traditional drive systems, Kimla’s proprietary linear drives provide extremely high accelerations and positioning speeds. This significantly reduces cutting times for complex shapes and increases the machine’s overall performance.

• 2 kW Fiber Source Power: The 2000 W fiber resonator strikes an ideal balance between speed and cutting capability. It enables efficient machining of mild steel, stainless steel, aluminum, and also non-ferrous metals such as copper or brass (subject to consultation with the manufacturer), all with excellent edge quality.

• High Energy Efficiency: Fiber laser technology is considerably more energy-efficient compared to CO₂ lasers. This translates into lower electricity costs and reduced environmental impact.

• Monolithic, Rigid Design: The machine body is manufactured as a single, solid element, ensuring exceptional stability and vibration resistance, even at the highest processing speeds. This directly contributes to superior cutting accuracy and repeatability.

• Intuitive Software: The integrated Kimla control system and software are operator-friendly, enabling rapid project preparation (CAD/CAM) and complete control over the cutting process.

• Low Operating Costs: With no optical components requiring frequent maintenance (like mirrors in CO₂ lasers) and a long-life fiber resonator, maintenance costs and service downtimes are minimized.

Lhedpfsw Izayox Af Ieb

Technical Specifications:

Model: Kimla LF 1020 Powercut

Laser Resonator Power: 2 kW (2000 W)

Resonator Type: Fiber

X/Y Working Area: 1000 mm x 2020 mm

Axis Drives: Magnetic linear

Control System: Integrated Kimla system

Applications:

The Kimla LF 1020 laser is the ideal tool for:

• Sheet metalworking and metal fabrication companies

• Manufacturers of machinery, equipment, and steel structures

• Automotive sector

• Advertising industry (visual elements, 3D letters)

• Producers of metal furniture and interior fitting components

Mažas skelbimas

Zona Industriale "scerne"

Zona Industriale "scerne"

1 566 km

CNC BRIAUNŲ APDIRBIMO CENTRAS

HOMAGBAZ 20/50/14/G

Skambinti

Sąlyga: labai geros būklės (naudotas), CNC Machining Center with Edgebanding Unit for Straight and Curved Panels

- 4-axis electrospindle with HSK F63 interface, for precise and versatile machining operations

- Automatic tool magazine with 12 positions, enabling rapid tool changes

- Integrated drilling head, ideal for drilling operations on a variety of materials

- Edgebanding unit for the precise application of edge banding on both straight and curved panels

- 3-position edge band magazine for efficient management of different edge types

Lsdpfx Aolpf E Ujf Iohb

- Vacuum pump for secure panel clamping during machining

Mažas skelbimas

Lukovica

Lukovica

1 192 km

Apdirbimo centras

SCMRECORD 110ALXLTWNPR

Skambinti

Sąlyga: geras (naudotas), Gamybos metai: 2010, veikimo valandos: 25 000 h, Funkcionalumas: visiškai funkcionalus, mašinos/transporto priemonės numeris: AA2/001307, X ašies eiga: 6 500 mm, Y ašies eiga: 1 700 mm, Z ašies eigos atstumas: 250 mm, greitas poslinkis X ašimi: 60 000 m/min, greitas poslinkis Y ašis: 45 000 m/min, greitasis eiga Z ašyje: 30 000 m/min, padavimo ilgis X ašis: 6 500 mm, padavimo eiga Y ašimi: 1 300 mm, padavimo ilgis Z ašis: 1 mm, X ašies padavimo greitis: 6 000 m/min, Y ašies padavimo greitis: 45 000 m/min, padavimo greitis Z ašis: 30 000 m/min, nominali (akivaizdi) galia: 15 kVA, valdiklių gamintojas: NUM, valdiklio modelis: 1040, ruošinio ilgis (maks.): 6 500 mm, ruošinio plotis (maks.): 1 350 mm, ruošinio aukštis (maks.): 180 mm, bendras aukštis: 2 750 mm, bendras ilgis: 8 000 mm, bendras plotis: 4 000 mm, stalo plotis: 1 350 mm, stalo aukštis: 950 mm, stalo ilgis: 6 500 mm, veleno greitis (min.): 24 000 aps./min, ašies variklio galia: 11 W, Delovne smeri osi X-Y-Z: 6500 x 1350 x 250 mm

Delovno območje: 6500 x 1250 mm

C-os = 640, B-os = 270

Rezkalna enota PRISMA s 5 interpolacijskimi osmi: X, Y, Z, C, B

Električno vreteno 11 kW, 600–20.000 min⁻¹

Orodni držalo HSK63

Delovna miza s TVN blazinicami in vakuumskimi priseski

Križni laserski projektor na delovni mizi

TVN vakuumski prisesek

Pnevmatske sponke

Lhjdow Au N Sjpfx Af Ieb

Orodni magazin za 24 orodij

Vrtalna enota

Vakuumska črpalka 5,5 kW, 250 m³/h

CNC krmilnik NUM, operacijski sistem: Windows XP

Xilog Plus

Maestro

Teža cca 5450 kg

Mažas skelbimas

Jonava

Jonava

27 km

Apdirbimo centras

WOODLAND MACHINERY1325

Skambinti

Sąlyga: naujas, Type 1325

Useful working area axis X-Y-Z 1300-2500-200 mm

Spindle, air-cooled, 6kw, 18000 rpm.

Engine Hybrid servo

Ledpfx Aeq Tn I Njf Ijhb

Drive system LAAK

Work table vacuum plate

Vacuum pump 7.5kw

Maximum speed 25,000 mm/min (x y) 10,000 mm/min ( Z )

Working speed 10-15M/MIN

Power 380V/50HZ

Code G

Transport dimensions 3200x2100x1800mm

Weight 1600 kg

Price 9600 Eur (EXW Jonava, Lithuania)

Mažas skelbimas

Jonava

Jonava

27 km

Mechaninio apdirbimo centras

SCM RoutechRecord 121

Skambinti

Sąlyga: naudotas, Gamybos metai: 2001, Tipas: Record 121

Darbo ašių skaičius: 3+

Lhjdpfxsv Dtibj Af Ieb

Naudinga darbo sritis X-Y-Z ašyse: 2600-1080-250 mm

Stalo matmenys: 2600 x 1080 mm

Veleno apsukų diapazonas: 900 - 18 000 aps./min.

Frezuojančių velenų skaičius: 1

Įrankių keitimo pozicijų skaičius: 12

Įrankių tvirtinimo sistema: HSK63F

Darbinis stalas: matricinis stalas

Pagrindinis variklis: 7,5 kW

Vakuuminio siurblio našumas: 250/300 m³/h

Vakuuminio variklio galia: 6,5 kW

Ištraukimo jungties skersmuo: 150 mm

Suslėgto oro slėgis: 7 bar

Įtampa: 380V/50HZ

Transporto matmenys: 3700 x 3200 x 2600 mm

Svoris: 3500 kg

Kaina: 15 500 Eur

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Jonava

Jonava

27 km

Mechaninio apdirbimo centras

WOODLAND MACHINERYSX1325A-12

Skambinti

Sąlyga: naujas, Typ SX1325A-12

Lhsdpferxtvkex Af Ijb

Nutzbarer Arbeitsbereich Achse X-Y-Z: 2850-2100-150 mm

Spindel, luftgekühlt, 9,0 kW, 24.000 U/min

Servomotor

Steuerungssystem: LNC

Zahnstangenantrieb

Hochpräziser automatischer Positionierzylinder

Arbeitstisch: Vakuumplatte

Vakuumpumpe: 7,5 kW

Maximale Geschwindigkeit: 60 m/min

Maximale Arbeitsgeschwindigkeit: 15–20 m/min

Flexibles Schleppkabel (mit Abschirmung)

Pneumatikkomponenten: BLCH

Spannung: 380V/50Hz

Transportmaße: 3200x2100x1800 mm

Gewicht: 3100 kg

Preis: 24.500 EUR

Mažas skelbimas

Jonava

Jonava

27 km

Mechaninio apdirbimo centras

woodland machineryCK-3000B

Skambinti

Sąlyga: naujas, Tipas: CK-3000B

Darbinio stalo aukštis: 800 mm

Apdirbimo gylis: 65 mm

Apdirbimo ilgis: 3100 mm

Judesio valdiklis: Loran

Didžiausias važiavimo greitis: 150 m/min

Didžiausias darbinis greitis: 105 m/min

Valdymo sistema: TPR

Lhodpfx Asqxtf Dsf Ijb

Veleno galia: 2x 2,2 kW

Veleno apsukos: 0–18000 aps./min

Keitiklis: Jiale

Oro slėgis: 0,6–0,8 MPa

Variklių galia: 750+750+400 W

Transportavimo matmenys: 4200x1700x1400 mm

Svoris: 900 kg

Kaina: 6499 Eur (EXW Jonava, Lietuva)

Mažas skelbimas

Jonava

Jonava

27 km

Mechaninio apdirbimo centras

WOODLAND MACHINERYSX1325A-4

Skambinti

Sąlyga: naujas, Тип SX1325A-4

Полезная рабочая область по осям X-Y-Z: 2850×2100×150 мм

Шпиндель: воздушное охлаждение, 6 кВт + 3×4,5 кВт, 18 000 об/мин

Ledpfx Afjrxtwdo Ishb

Привод: гибридный серводвигатель

Система управления: LNC

Повторяемость позиционирования: 0,03 мм

Рабочий стол: вакуумная плита

Вакуумный насос: 11 кВт

Максимальная скорость перемещения: 50 000 мм/мин

Максимальная рабочая скорость: 25 000 мм/мин

Разрешающая способность: ±0,05 мм

Разрешение системы: ±0,001 мм

Код: G

Инвертор: 7,5 кВт

Напряжение: 380В/50Гц

Транспортировочные габариты: 3200×2100×1800 мм

Масса: 2100 кг

Цена: 23 100 евро

Mažas skelbimas

Jonava

Jonava

27 km

20-75-810 įdėjimo mašina

WOODLAND MACHINERYSX1325AP-2128

Skambinti

Sąlyga: naujas, Typ: SX1325AP-2128

Achsen:

Nutzbarer Arbeitsbereich X-Y-Z: 2070 x 2800 x 100 mm

Werkstückhöhe in Z: 100 mm

Max. Verfahrgeschwindigkeit: 70 m/min

Max. Arbeitsgeschwindigkeit: 30 m/min

Arbeitstisch:

Mehrzwecktisch aus Phenolharz

Standard-Anschläge: 10 (4X-6Y)

Vakuumpumpe: 4 x 5,5 kW (50/60 Hz), luftgekühlt

Elektrospindel:

Standardleistung (S6): 9,5 kW, ISO30

Max. Drehzahl: 24.000 U/min

Werkzeugwechsler:

ATC-Karussell mit 12 Plätzen

Schmierung:

Automatische zentrale Schmierung

Installation:

Installierte Leistung: 22-33 kW

Druckluftverbrauch: 450 NL/min

Absaugluftverbrauch: 3.000 m³/h

Absaugluftgeschwindigkeit: 25 m/sec

Absaughauben-Durchmesser: 2 x 150 mm

Hergestellt in China

Lhsdsdz Edqepfx Af Isb

Gewicht: 3.500 kg

Mes supaprastiname jums paiešką

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota apdirbimo centrai su lygiuoju arba rastro stalu (347)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- As 1050

- Automobilių Dirbtuvės

- Cnc Frezavimo Staklės Ir Apdirbimo Centras

- Darbuotojų Saugos Ir Sveikatos

- Ex Spaudos Centras

- Ga 11 Ff

- German

- Hh Saugiklis

- Id 5005

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo