Apverčiamųjų stalų kombinacija medinių karkasų statybaiRandek AB

BS20

Apverčiamųjų stalų kombinacija medinių karkasų statybai

Randek AB

BS20

Gamybos metai

2026

Sąlyga

Naujas

Vieta

Falkenberg

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Apverčiamųjų stalų kombinacija medinių karkasų statybai

- Gamintojas:

- Randek AB

- Modelis:

- BS20

- Gamybos metai:

- 2026

- Sąlyga:

- naujas

Kaina ir vieta

- Vieta:

- Falkenberg, Schweden

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A896820

- Nuorodos Nr.:

- BS20

- Naujinta paskutinį kartą:

- Data 2026.01.22

Aprašymas

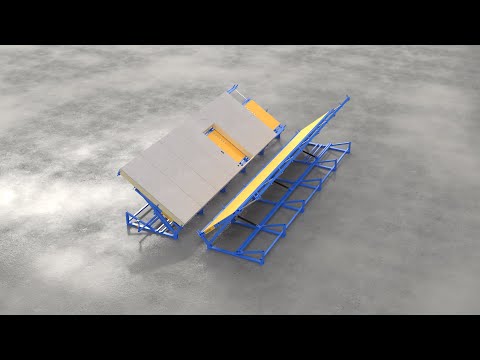

Tilting Table Combination for Timber Frame Construction - BS20

The Randek tilting table combination is an efficient tool for the production of prefabricated walls, roofs, floors, and gable elements using timber or metal frames. The tables can be operated as stand-alone units or integrated into production lines. Precisely right-angled building components of high quality are achieved thanks to the clamping function. Raising and tilting of the components is performed via a controlled, manually supervised process. The tilting table combination has been developed for the manufacture of prefabricated houses, ensuring high productivity.

The adjustable element height ranges from 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The tilting table combination has been designed to efficiently carry out the following operations: frame assembly, insertion of insulation material, stapling of plastic or paper membranes, and application and nailing of wall claddings.

• Production of right-angled components: the pneumatic clamping mechanism along the long side of the master table presses the frame structure into a right-angled, high-quality, highly accurate component

Bleds Nn Hyepfx Abfsc

• Automatic tilting of the component (manual control)

• Automatic raising of the component

Technical Description:

• Length options: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Width adjustment between 2250 – 3100 mm; manual adjustment is straightforward

• The master table is hydraulically tiltable up to 92°, the receiver table up to 86°

• Pneumatically actuated pressing function on the longitudinal side of the master table

• 160 mm high stops

• Both tables are faced with plywood panels where technically feasible; the plywood facing enables direct placement of sub-components and beams

• The tabletops are supported by a robust steel frame

• Optimum working height of 620 mm

• Longitudinal C-profiles for positioning stops for studs

• Tables are delivered ready for assembly; the assembly process is straightforward

Safety:

• Emergency stop switch on the control panel

• CE conformity

Advantages:

• Precisely right-angled components thanks to the pressing function

• Controlled automatic raising and tilting of components

• Ideal working height

• Flexible width adjustment

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

The Randek tilting table combination is an efficient tool for the production of prefabricated walls, roofs, floors, and gable elements using timber or metal frames. The tables can be operated as stand-alone units or integrated into production lines. Precisely right-angled building components of high quality are achieved thanks to the clamping function. Raising and tilting of the components is performed via a controlled, manually supervised process. The tilting table combination has been developed for the manufacture of prefabricated houses, ensuring high productivity.

The adjustable element height ranges from 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The tilting table combination has been designed to efficiently carry out the following operations: frame assembly, insertion of insulation material, stapling of plastic or paper membranes, and application and nailing of wall claddings.

• Production of right-angled components: the pneumatic clamping mechanism along the long side of the master table presses the frame structure into a right-angled, high-quality, highly accurate component

Bleds Nn Hyepfx Abfsc

• Automatic tilting of the component (manual control)

• Automatic raising of the component

Technical Description:

• Length options: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Width adjustment between 2250 – 3100 mm; manual adjustment is straightforward

• The master table is hydraulically tiltable up to 92°, the receiver table up to 86°

• Pneumatically actuated pressing function on the longitudinal side of the master table

• 160 mm high stops

• Both tables are faced with plywood panels where technically feasible; the plywood facing enables direct placement of sub-components and beams

• The tabletops are supported by a robust steel frame

• Optimum working height of 620 mm

• Longitudinal C-profiles for positioning stops for studs

• Tables are delivered ready for assembly; the assembly process is straightforward

Safety:

• Emergency stop switch on the control panel

• CE conformity

Advantages:

• Precisely right-angled components thanks to the pressing function

• Controlled automatic raising and tilting of components

• Ideal working height

• Flexible width adjustment

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Dokumentai

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+49 5721 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Hilzingen

Hilzingen

1 328 km

Sienų linijos ištisinė sistema namo statybai

Mažas skelbimas

Zielona Góra

Zielona Góra

654 km

Stalių staklės

BOOSTONER-02

BOOSTONER-02

Mažas skelbimas

Vokietija

Vokietija

999 km

Skydo pjūklas

FELDERFORMAT 4 KAPPA 550

FELDERFORMAT 4 KAPPA 550

Mažas skelbimas

Kanzach

Kanzach

1 262 km

Sausa paternoster pirštų sujungimo linija

WEINIG

WEINIG

Mažas skelbimas

Cochem-Brauheck

Cochem-Brauheck

1 258 km

Lengvojo metalo / aliuminio diskinis pjūklas

MTIAS-800

MTIAS-800

Mažas skelbimas

Vokietija

Vokietija

872 km

Vienos sijos tiltinis kranas

DemagEHK 10000-21000

DemagEHK 10000-21000

Mažas skelbimas

Nersingen

Nersingen

1 204 km

KVH ir BSH gamybos mechanizavimas

HIT

HIT

Mažas skelbimas

Bautzen

Bautzen

768 km

Kūgio trupintuvas Krupp Kupria 90/1-08

KruppKrupp Kupria 90/1-08

KruppKrupp Kupria 90/1-08

Mažas skelbimas

Bad Honnef

Bad Honnef

1 216 km

Vakuuminis keltuvas BARBARIC B3, pasukamas, su kranu - Parodos įrenginys -

BARBARICVakuumheber B3 schwenkbar, inkl. Kran

BARBARICVakuumheber B3 schwenkbar, inkl. Kran

Mažas skelbimas

Gerolzhofen

Gerolzhofen

1 085 km

Pjūklas ilgiui pjauti ir įstrižinis pjūklas

GRAULEZS 135

GRAULEZS 135

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida