Pneumatiniai Įsriegimo Staklės pirkti naudotą (48 366)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Mažas skelbimas

Siedlce

Siedlce

352 km

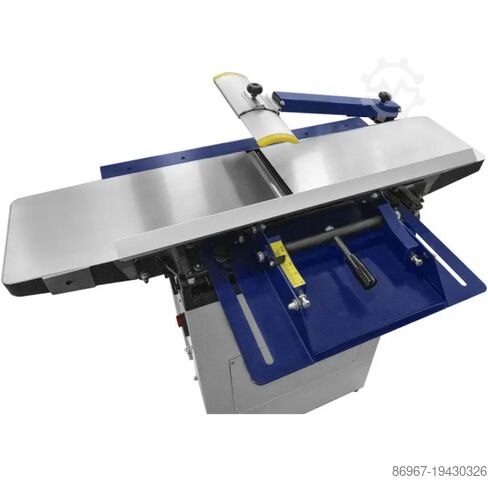

Obliavimo staklės

CORMAKPT250 230V

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Surface planers-thicknessers, planing machines in the Cormak range

Our store offers a wide selection of professional, versatile planers that combine stable operation and high surface accuracy with an attractive price point. Gain a machine that will accelerate your production and enhance the quality of your wooden products—even for amateur applications in home workshops. Cormak guarantees satisfaction.

Construction and operation of a planer

Table: The thicknesser table is made from high-quality ground cast iron, with a polished working surface up to Ra 1.6 finish. Table height adjustment is handled by a large, easy-to-use handwheel, which can be locked in place with an additional eccentric lever once the desired height is set.

Knives: A key component of every planer, knives are located above or below the table and remove excess material from the wood surface. These knives are mounted on a rotating cutter block or head.

Motor: The planer is powered by an electric motor that delivers the energy needed to drive the cutter block or planer head.

Cutterhead guard: The shaft guard can be freely adjusted in terms of height, angle, and length of extension.

Feed mechanism: The woodworking machine is equipped with feed rollers (drive and outfeed) placed close to the cutter shaft, enabling even relatively short workpieces to be fed through the thicknesser. The feed rollers are chain-driven, guaranteeing a slip-free operation (eliminating marking on the machined workpiece).

Guides: Guides help maintain consistent movement of the material. The angle fence can be smoothly set anywhere between 90° and 45°.

Stability: The machine’s substantial weight ensures solid stability, allowing for safe work free from vibrations, enhanced further by additional anti-vibration feet.

Ease of use: Adjustments are straightforward, and converting the machine from surfacer to thicknesser function takes only a few seconds.

Technical specifications of the thickness planer:

Cutter block diameter [mm]: 75

Cutter block speed [rpm]: 4000

Dust extraction port diameter [mm]: 100

Fence tilting angle [°]: 0–45

Number of knives: 3

Knife size [mm]: 250x30x3

Max planing width (surface planer) [mm]: 254

Max planing width (thicknesser) [mm]: 254

Max planing height [mm]: 180

Max depth of cut (thicknesser) [mm]: 3

Max depth of cut (surface planer) [mm]: 2.5

Feed speed (thicknesser) [m/min]: 6

Dimensions (L x W) [mm]: 1080 x 260

Ffsdpfxevxh Nxo Ab Sst

Gross weight [kg]: 152

Motor power: 2.6 kW

Power supply: 230V

Mažas skelbimas

Lenkija

Lenkija

478 km

Horizontalios tekinimo staklės

HAASST-20Y

Skambinti

Sąlyga: paruoštas naudoti (naudotas), Gamybos metai: 2019, veikimo valandos: 3 728 h, veleno greitis (maks.): 4 000 aps./min, X ašies eiga: 213 mm, Y ašies eiga: 51 mm, Z ašies eigos atstumas: 572 mm, ašies variklio galia: 149 000 W, Strypo skersmuo (maks.): 64 mm, valdiklių gamintojas: HAAS, valdiklio modelis: NGC, įrankių magazino lizdų skaičius: 12, C ašies pasukimo kampas (maks.): 360 °, ašių skaičius: 4, Valdymo blokas

Gamintojas: HAAS

Modelis: NGC

Ffjdpfxjx D Hn Tj Ab Set

Pagrindinė pavara

Veleno anga: 88,9 mm

Ašių skaičius: 4

Veleno apsisukimų dažnis: 4000 aps./min

Veleno variklio galia: 149 kW

Judesiai

X ašies eiga: 213 mm

Z ašies eiga: 572 mm

Y ašies eiga: 51 mm

C ašies eiga: 360º

Įrankiai

Sandėliavimo vietų skaičius: 12

Techninė specifikacija

Didžiausias ruošinio skersmuo: 64 mm

Varomi įrankiai: yra

Šis HAAS ST-20Y tekinimo staklės, pagamintos 2019 m., turi Y ašį, užpakalinio centro atramą, automatinį įrankio matuoklį bei drožlių transporterį. Maksimalus veleno apsisukimų dažnis – iki 4000 aps./min., o varomi įrankiai, valdoma C ašimi, užtikrina dideles sudėtingo apdirbimo galimybes. Jei ieškote aukštos kokybės tekinimo sprendimo, apsvarstykite mūsų siūlomą HAAS ST-20Y. Susisiekite dėl išsamesnės informacijos.

Pritaikymo sritys

Tekinimas

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAKTORNADO 460x1500

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Industrial metal lathe CORMAK TORNADO 460x1500 – featuring a cast base twice the standard thickness and a robust cast iron bed, equipped with a 12-speed gearbox and a powerful 5.5 kW / 400V induction motor delivering maximum torque and a large 82 mm spindle bore.

Key advantages:

- Versatility of applications: This lathe is perfect for a wide variety of tasks, including internal and external turning, taper turning, threading (metric, inch, module, DP), polishing, drilling, and broaching.

- Stable construction: The 300 mm wide cast iron bed is hardened and precisely ground, ensuring substantial vibration reduction and stable operating conditions even under heavy loads.

- Digital precision: The machine is fitted with a dual-axis digital readout (longitudinal and cross) displaying precise displacement values on screen via optical measuring scales.

- High-quality spindle: A reinforced bearing system and large 82 mm spindle bore ensure optimal performance. Included are a 3-jaw chuck (250 mm), a 4-jaw chuck (320 mm), and a 5.5 kW motor.

- Efficiency and productivity: Rapid longitudinal and cross feed via joystick significantly reduces machining time, while hardened and ground gears in the spindle gearbox guarantee durability and long-term reliability.

- Wide threading capability: Thread cutting functions for metric, inch, module, and DP threads (right and left-handed) with adjustable parameters without gear wheel changes, for faster and more convenient operation. Supported threads include: metric (41 ranges) from 0.1 to 14 mm, inch (60 ranges) from 2 to 112 TPI, module (34 ranges) from 0.1 to 7 M.P., and DP (50 ranges) from 4 to 112 D.P.

- Precise thread counting: Equipped with a thread dial indicator, enabling quick repositioning of the carriage after disengaging the leadscrew nut.

- Ergonomics and ease of use: An intuitive control panel on the gearbox allows for quick adjustments of spindle speed and automatic feed rate.

- Large workpiece capability: The removable gap bed section enables turning of workpieces up to 690 mm in diameter and 240 mm in length (with gap removed), expanding the machine’s capabilities.

Technical specifications:

Turning diameter over bed ø460 mm

Turning diameter over cross slide ø274 mm

Turning diameter with gap (diameter x width) 690 mm x 240 mm

Centre height 230 mm

Distance between centres 1500 mm

Bed width 300 mm

Max tool shank size 25 x 25 mm

Total cross slide travel 290 mm

Total top slide travel 120 mm

Spindle bore diameter ø82 mm

Ffsdpfxovzzqbj Ab Sjt

Spindle nose D1-8

Spindle taper ø90 (1:20)

Number of spindle speeds 12

Spindle speed range 25–2000 rpm

Lead screw diameter and pitch ø35 mm x 6 mm

Imperial threads Pitch 2–112 TPI (60)

Metric threads 0.1–14 mm (41)

DP gears 4–112 D.P. (50)

Module gears 0.1–7 M.P. (34)

Longitudinal feed 0.031–1.7 mm/rev (42)

Cross feed 0.014–0.784 mm/rev (42)

Tailstock quill travel 120 mm

Tailstock quill diameter ø60 mm

Quill taper MT No. 4

Spindle drive motor 5.5 kW

Coolant pump motor 0.09 kW

Machine dimensions (LxWxH) 2720 x 1040 x 1340 mm

Weight 2445 kg

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

Siedlce

Siedlce

352 km

Vamzdžių lenkimo staklės

CORMAKRBM50

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Electric pipe and profile bending machine for bending tubes, profiles, rods, and flat bars depending on the type of installed rollers – bending dies. The machine is additionally equipped with a mechanical upper roller pressure system with vernier scale. An ideal solution for bending arches, circles, spirals, etc. The substantial dead weight ensures optimal stability during operation. The set includes a foot pedal for left/right drive control. Used in locksmith workshops and on construction sites. Maximum pipe bending range up to 70 mm.

Machine Characteristics

- Bending radius adjustable via the top-mounted pressure device with vernier scale

- Application: bending profiles and pipes

- Capability to bend various profiles thanks to universal rollers

- Substantial dead weight ensuring optimal stability

- Side-guided rollers, ground and hardened

- Bending rollers made of durable, hardened steel

Fjdpfx Aou Snkgjb Ssft

- Operation via foot pedal

- Left/right operation

Standard Equipment

- Side guide rollers

- Foot pedal

- Universal rollers

- Polish language technical documentation

- CE declaration

Technical Data

Round pipe [mm]: Ø 70 x 2

Rectangular profile [mm]: Ø 60 x 60 x 3

Round rod [mm]: Ø35

Solid rectangular element [mm]: Ø 35 x 35

Roller diameter [mm]: 50

Motor power [kW]: S1 1.5/ S6 2.2

Power supply: 3 phase, 400 V

Dimensions (LxWxH): 900 x 850 x 1700

Weight [kg]: 550

Mažas skelbimas

Siedlce

Siedlce

352 km

Diskinių pjūklų galandinimo staklės

CORMAKJMY-870

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, The JMY-870 circular saw blade sharpener is an excellent tool designed for sharpening circular saw blades. The sharpener is equipped with a durable diamond grinding wheel, ensuring precise and efficient sharpening. Its robust cast iron construction guarantees stability during operation, while the adjustable blade tilt and bevel angle provide full control over the sharpening process. Additionally, rubber foot pads minimize noise, ensuring operator comfort. The unit comes standard with a 125 mm diamond grinding wheel and is suitable for sharpening blades ranging from 80 mm to 700 mm in diameter.

Key features of this circular saw blade sharpener:

- The sharpener is fitted with a high-quality 125 mm diameter diamond grinding wheel, which ensures remarkable precision when sharpening carbide-tipped saw blades.

- The cast iron base ensures stability during operation, providing users with confidence that the machine will neither wobble nor vibrate during sharpening.

- The unit is equipped with a tilting blade support bracket, enabling adjustment of the tilt angle from -35° to +45°, allowing precise adaptation to user-specific requirements.

- An additional function is the ability to set the blade’s bevel angle from +85° to -30°, making it possible to adapt the tool to various types of saw blades.

- Operator comfort has been prioritized in the design; the rubber foot pads allow the device to run almost silently, enhancing user experience.

Fodsu Tti Iepfx Ab Sjft

Application of the circular saw blade sharpener:

This sharpener is designed for sharpening circular saw blades. The operation of the device is intuitive and straightforward, making it accessible even to users unfamiliar with technical tools. The JMY-870 circular saw blade sharpener is a professional device that ensures high-quality blade maintenance and excellent working comfort. Thanks to its versatile adjustment features, it is an excellent choice for users who require a precise and efficient tool for sharpening a variety of circular saw blades.

THE KIT INCLUDES A DIAMOND GRINDING WHEEL!

Technical specifications:

MIN/MAX BLADE DIAMETER: 80 mm - 700 mm

HORIZONTAL BLADE HOLDER TILT: -35° to +45°

GRINDING ASSEMBLY INCLINATION: -20° to +20°

GRINDING WHEEL SPEED: 2850 RPM

WHEEL DIMENSIONS: 125 x 10 x 13 mm

MOTOR POWER: 0.25 kW

SUPPLY VOLTAGE: 230 V

NET WEIGHT: 21 kg

DEVICE DIMENSIONS: 750 x 750 x 350 mm

Mažas skelbimas

Siedlce

Siedlce

352 km

CNC tekinimo staklės

CORMAKCNC CKT 320x750 SAM6

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Efficient CNC Lathe CORMAK 320x750 SAM6 with Optional Equipment Tailored to Your Needs.

Thanks to a variety of optional equipment, you can configure the lathe to suit your requirements. Choose from different controls, such as the SINUMERIK 828, add a tool probe for automatic measurement, or a hydraulic chuck for fast and convenient handling. A wide range of additional options, such as a travelling steady, internal cabin mist separator, or even CAD/CAM software, makes this lathe a versatile tool ready to tackle even the most demanding tasks.

Technical data

TURNING DIAMETER OVER BED: 320 mm

TURNING DIAMETER OVER SLIDE: 90 mm (option: 135 mm)

DISTANCE BETWEEN CENTRES: 750 mm

SPINDLE SPEED: 100–2500 rpm

SPINDLE BORE: 60 mm

SPINDLE NOSE: MT5

NUMBER OF TOOLS: 6

TOOL SIZE: 16x16 mm

MAXIMUM SHAFT DIAMETER THROUGH SPINDLE: 44 mm

TAILSTOCK QUILL TAPER: MT3

MAXIMUM TAILSTOCK STROKE: 100 mm

MOTOR POWER: 5.1 kW (S1) / 3.7 kW

DIMENSIONS: 2370 x 1420 x 2000 mm

Fodpfowtnvmjx Ab Sjft

NET/GROSS WEIGHT: 1040/1300 kg

Standard equipment

- SINUMERIK 808D control (Polish language)

- SIEMENS servo drives

- 3-jaw manual lathe chuck

- 6-position turret head

- Set of soft jaws

- Manual tailstock

- Cooling system

- Automatic lubrication system for gears and guides

- 24V halogen lighting

- Technical documentation (Polish)

- CE declaration

Optional equipment

- Available controls: SINUMERIK 828, FANUC, GSK

- Hydraulic chuck

- Hydraulic tailstock

- Travelling steady

- Fixed steady rest

- Tool probe

- Additional soft jaws

- Hard jaws

- Collet chucks

- Finished parts catcher

- Bar feeder

- Internal cabin mist separator

- Used oil separator from coolant

- Tool holders

- CAD/CAM software

Mažas skelbimas

Siedlce

Siedlce

352 km

Obliavimo staklės

CORMAKPT265 230V

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, The Cormak PT265 jointer-planer is a robust and well-engineered machine, offering extensive adjustment possibilities and the capability to process both hard and soft wood mechanically. Adjusting the planer is straightforward and switching between jointer and thicknesser modes takes just a few seconds.

Latest machine version with an innovative table opening system:

❌ Competing machines of the older design use 'butterfly' tables. Before each operation, the infeed and outfeed tables must be recalibrated relative to each other. Even slight misalignments can cause material damage and undesired results.

✔️ The new interconnected table system allows for precise, simultaneous adjustment of both tables. Once set, the tables remain permanently calibrated. When changing the planing height, both tables move in sync.

✔️ This solution not only saves time and increases working comfort but also improves planing accuracy by up to 30% compared to older systems. This enhancement is particularly crucial when working with thinner materials.

Stable, vibration-resistant construction

The machine’s substantial weight of 170 kg, combined with wide, ground cast iron tables (265 mm), ensures a high level of stability and safe operation.

Additional rubber feet enable operation without any noticeable vibration.

VERSION with the most powerful S6: 2.6 kW motor

The PT265 jointer-planer features an exceptionally powerful S6 2.6 kW (S1 2.2 kW) motor—significantly exceeding what competitive models offer, resulting in enhanced performance and stable operation.

A more powerful motor ensures stable operation and makes processing hardwoods effortless: Hard timber requires greater force for machining, which this robust motor handles with ease.

Effortless mode change from jointer to thicknesser

Switching from jointer to thicknesser mode is very quick and easy. It only requires unlocking the eccentrics, lifting the tables, and repositioning the chip extraction hood.

High working precision

Ffodpfx Aewu T S Aeb Set

- Smooth height adjustment of the tables with scale.

- The thicknessing table is centrally column-supported and equipped with a handwheel for up and down adjustments.

- Aluminum tilting fence (700x150 mm) with scale allows for precise angle setting from 90 to 45 degrees.

Technical specifications:

Knife shaft diameter [mm]: 75

Knife shaft speed [rpm]: 4000

Suction port diameter [mm]: 100

Tilting fence angle [°]: 90 - 45

Number of knives: 3

Shaft length [mm]: 262

Knife dimensions [mm]: 250x30x3

Max. planing width (jointer) [mm]: 265

Max. planing width (thicknesser) [mm]: 265

Max. planing height [mm]: 180

Max. planing depth (thicknesser) [mm]: 3

Max. planing depth (jointer) [mm]: 2.5

Thicknesser feed speed [m/min]: 6

Fence dimensions [mm]: 700 x 150

Machine dimensions (L x W) [mm]: 1080 x 269

Weight [kg]: 170

Total motor power: S6: 2.6 kW

Power supply: 230V

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAKTORNADO 360x1000

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, CORMAK 360 Metal Lathe – New, Upgraded Model!

The CORMAK 360 metal lathes are a new and improved version of the popular machines for metalworking. Upgrades include an enhanced tool post guard, improved spindle bearing system, and a new digital readout. These lathes are suitable for production facilities, workshops, and toolrooms, making them ideal for small batch and one-off production.

Key Upgrades:

- High-quality, reinforced spindle bearing system

- New CE-compliant guard system

- Latest axis digital readout model

- Reinforced and modernized lathe base with tool drawers and chip tray

Machine Features

- Reinforced, ribbed bed for maximum vibration reduction; precision ground and hardened

- Digital axis readout as standard

- Large spindle bore (52 mm) ensures optimal machining performance

- Adequate bed width for stable and precise operation

- The machine is equipped with a high-quality, reinforced spindle bearing system

- Efficient machining thanks to two automatic feeds and lead screw/feed shaft equipment

- Hardened gears in the spindle gearbox

- Adjustable overload clutch on the lead shaft

- Full thread cutting range without changing gear wheels

- Feed selection lock: by screw or by shaft

- Removable gap bridge for machining workpieces of increased diameter

- Removable chip tray and tool drawers for improved workflow

Technical Specifications

- Max turning diameter: 360 mm

- Max turning diameter over carriage: 220 mm

- Max turning diameter in gap: 490 mm

- Max turning length in gap: 168 mm

- Turning length between centres: 970 mm

- Bed width: 187 mm

- Spindle nose: D1-4

- Spindle bore: 52 mm

- Spindle speed range: 90-2000 rpm

- Number of spindle speed ranges: 8

- Longitudinal feed range: 0.055 – 1.291 mm/rev

- Cross feed range: 0.014 – 0.345 mm/rev

- Max tool size: 16 x 16 mm

- Metric thread: 0.4 – 7 mm

- Imperial thread: 4 – 60 TPI

- Tailstock quill diameter: 32 mm

- Tailstock quill taper: MT3

- Main motor power: 1.5 kW

- Coolant pump power: 0.1 kW

- Weight: 570 kg

- Dimensions: 1890 x 720 x 1500 mm

Standard Equipment

- Digital axis readout

- 3-jaw lathe chuck (200 mm)

- 4-jaw lathe chuck (200 mm)

- Faceplate

- Fixed steady

- Travelling steady

Fsdpfxeiz S R Ne Ab Sjft

- Reducing sleeve

- Fixed centre

- Coolant system

- Work light

- Change gear set

- Thread dial indicator

- Service tools

- Lathe base

- Operating manual (Polish)

- EC/CE declaration of conformity

- Brand new machine – full warranty

For more information, please visit our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAK410x1000

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, This series of lathes can be used for a wide range of machining operations such as internal and external turning, taper turning, polishing, threading (metric, inch, modular, and DP), drilling, and internal broaching.

Machine Features:

- The 410x1000 CORMAK series lathe is suitable for diverse applications, including internal and external turning, taper turning, polishing, metric, inch, modular, and DP threading, drilling, and broaching.

- Standard equipment includes a full 3-axis digital readout system.

- Modern, high-precision spindle bearings.

- Large spindle bore: 52 mm.

- Heavy-duty cast-iron bed, ground and induction-hardened for durability and precision.

- Gear transmission with heat-treated and finely ground gears.

- Increased machining capacity thanks to removable bridge segment.

- Safety guards compliant with the latest standards.

- Machining accuracy: roundness deviation below 0.01 mm, cylindrical deviation not greater than 0.02 mm over 200 mm measurement; outstanding surface finish.

- Equipped with a mechanical foot brake.

- Option to retrofit the lathe with a taper turning attachment.

Technical Specifications:

SWING OVER BED: 410 mm

SWING OVER CROSS SLIDE: 255 mm

SWING IN BED GAP: 580 mm

TURNING LENGTH IN GAP: 190 mm

BETWEEN CENTRES: 1000 mm (optional 1500 mm)

CENTRE HEIGHT: 205 mm

BED: induction-hardened

BED WIDTH: 250 mm

SPINDLE BORE: 52 mm

SPINDLE NOSE: D1-6

SPINDLE TAPER: No. 6 Morse

SPINDLE SPEED RANGE: (16) 45–1800 rpm

MAX TOOL SIZE: 20 x 20 mm

LONGITUDINAL FEED RANGE: (17) 0.05–1.7 mm/rev

CROSS FEED RANGE: (17) 0.025–0.85 mm/rev

METRIC THREAD PITCHES: (42) 0.2–14 mm

INCH THREAD PITCHES: (45) 2–72 TPI

MODULE THREAD: 0.3–3.5 MP (18)

DP THREAD: 8–44 DP (21)

TAILSTOCK SLEEVE DIAMETER: 50 mm

TAILSTOCK SLEEVE TRAVEL: 120 mm

TAILSTOCK SLEEVE TAPER: MT 4

DIGITAL READOUT: Full 3-axis

MAIN MOTOR POWER (S1/S6): 2.2 kW / 3.3 kW

COOLANT PUMP MOTOR: 0.1 kW

OVERALL DIMENSIONS: 1940 x 850 x 1320 mm

WEIGHT (GROSS): approx. 1590 kg

Standard Equipment:

- 3-jaw chuck (200 mm)

- 4-jaw chuck (250 mm)

- 3-axis digital readout

- Face plate

- Fixed steady rest

- Travelling (follower) steady rest

- Spindle reducing sleeve

- Live centre

- Change gears for metric/inch threading

Ffsdpfeiz Tf Sox Ab Sjt

- Coolant system

- Lighting system

- Threading dial indicator

- Equipped with CE-compliant electromechanical foot brake

- Chip tray

- Complete set of service tools

- Latest CE-compliant safety guards

- Comprehensive operation manual in Polish

- EC/CE declaration of conformity

- Factory new machine with full warranty

For more information, please visit our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAK500x1500YC

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, INDUSTRIAL UNIVERSAL LATHE WITH TURNING DIAMETER - 500 mm, TURNING LENGTH - 1500 mm, AND SPINDLE BORE 105 mm

Machine Features

A modern, production-grade universal lathe, easy to operate, equipped with a 3-axis digital readout. Ideal for repair shops, tooling operations, and serial production.

- Versatile applications in general machine building, part manufacturing, series production, vocational training workshops, etc.

- Removable bridge enables machining of large-diameter workpieces.

- Modern spindle supported by ball bearings.

- Central feed switching system, lead screw and feed shaft for threading.

- Precise speed and feed controls.

- The machine bed is exceptionally torsion-resistant and vibration-free, ensuring fundamental prerequisites for high-accuracy turning.

Technical Specifications

TURNING DIAMETER OVER BED: 500 mm with LCD readout

TURNING DIAMETER OVER SLIDE: 300 mm

TURNING DIAMETER IN BRIDGE GAP: 710 mm

TURNING LENGTH IN GAP: 240 mm

DISTANCE BETWEEN CENTERS: 1500 mm

BED: inductively hardened

Fedpfx Abei Apqls Seft

BED WIDTH: 400 mm

CHUCK DIAMETER: 315 mm

SPINDLE BORE: 105 mm

SPINDLE NOSE: D1-8 CAMLOCK

SPINDLE TAPER: MT 6

SPINDLE SPEED RANGE: 36 - 1600 rpm (12 steps)

MAX TOOL DIMENSIONS: 25 x 25 mm

LONGITUDINAL FEED RANGE: 0.063 - 2.52 mm/rev

CROSS FEED RANGE: 0.027 - 1.07 mm/rev

METRIC THREADS: 1 - 14 mm (22 types)

INCH THREADS: 28-2 TPI (25 types)

MODULAR THREADS: 0.5-7 mm (18 types)

D.P. THREADS: 56-4 D.P. (24 types)

RAPID LONGITUDINAL FEED: 4.5 m/min

RAPID CROSS FEED: 1.9 m/min

TAILSTOCK QUILL DIAMETER: 75 mm

TAILSTOCK QUILL TRAVEL: 150 mm

TAILSTOCK QUILL TAPER: MT 5

DIGITAL READOUT: for 3 axes

MAIN MOTOR POWER: 7.5 kW

COOLANT PUMP POWER: 0.09 kW

OVERALL DIMENSIONS: 3132 mm x 975 mm x 1270 mm

NET WEIGHT: 3300 kg (3800 kg gross)

Available Equipment:

- 3-axis digital readout

- 3-jaw self-centering chuck, Ø315 mm

- 4-jaw independent chuck, Ø400 mm

- Faceplate

- Traveling steady rest

- Fixed steady rest

- Spindle reducing sleeve

- Fixed center

- Rapid carriage feeds

- Foot-operated emergency brake

- Full-length chip guard

- Latest CE-compliant safety covers

- Cooling system

- 24V halogen lighting system

- Threading dial indicator

- Complete set of service tools

- Operating manual in Polish

- EC Declaration of Conformity (CE)

For more information, please visit our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Radialinio gręžimo staklės

CORMAKZ3032x1000

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Large and stable radial drilling machine with a wide range of spindle speeds, ensuring precise and fast machining.

Ffedpfxoi D Daqo Ab Sjt

Machine features

- High weight and rigid construction provide stability and vibration-free operation

- Box table enables easy positioning and clamping of the workpiece

- Motorized arm height adjustment

- Control panel located at the front of the drill for improved efficiency and operator ergonomics

- Ground column surface ensures smooth, easy, and precise arm movement

- Manual locking of the drilling head and column arm

- Wide speed range allows for precise and efficient machining

Technical specifications

MAX. DRILLING DIAMETER Cast Iron: 32 mm; Steel: 32 mm

SPINDLE DISTANCE TO BASE 340 - 1125 mm

SPINDLE AXIS DISTANCE TO COLUMN SURFACE 330 - 890 mm

SPINDLE STROKE 215 mm

SPINDLE TAPER MT4

SPINDLE SPEEDS (6 steps) 75, 130, 240, 380, 660, 1200 rpm

SPINDLE FEED (3 steps) 0.10; 0.16; 0.25 mm/rev

HORIZONTAL SWIVEL ANGLE 180 degrees

MAIN MOTOR POWER 2.2 kW

WORKTABLE DIMENSIONS 500 x 330 x 294 mm

MACHINE DIMENSIONS 1400 x 660 x 2100 mm

WEIGHT 950 kg

The listed price is NET. Price does not include transport costs.

For more information, please contact us by phone or e-mail. We invite you to browse our full offer on our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Paviršiaus šlifavimo staklės

CORMAK400x1000 automatic

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Continuous-duty surface grinding machine for production use. Features a large grinding range and programmable SIEMENS PLC controller. Equipped with a modern, rigid design. The spindle head operates on two pairs of guideways. Automatic feeds on three axes, digital readout as standard.

Machine Features

- Automatic feeds on 3 axes

- Digital readout

- Robust construction

- High precision

Technical Specifications

Work table size: 406 x 1020 mm

Table slot: 14 x 3 mm

Longitudinal table movement speed: 7~23 m/min

Maximum distance from table surface to spindle center: 570 (460) mm

Maximum load capacity (including fixture): 600 kg

Automatic intermittent feed (cross table movement): 0.1~8 mm

Rapid traverse (cross table movement): 990 mm/min

Handwheel feed: 0.02 (0.001") mm, 5 (0.2") mm

Grinding wheel size: 350 x 40 x 127 mm

Grinding wheel speed: 1450 rpm

Auto-feed (vertical movement): 0.005/0.01/0.02/0.03/0.04/0.05 mm

Rapid traverse (vertical movement): 480 mm/min

Handwheel feed (vertical movement): 0.005 (0.0002") mm/div., 1 (0.04") mm/rev.

Spindle motor: 5.5 kW

Oil pump motor: 2.2 kW

Ffjdpjkkdp Iofx Ab Sst

Coolant pump motor: 0.14 kW

Vertical drive motor: 1 kW

Cross drive motor: 0.04 kW

Weight: 4000 kg

Machine dimensions: 4400 x 2400 mm

Version-dependent equipment

- Digital readout

- Magnetic table 406 x 1020 mm

- Grinding wheel

- Grinding wheel balancing arbor

- Grinding wheel flange

- Cooling system

- Grinding wheel dresser

- Chip separator

- Halogen lighting system

The listed price is NET. Price does not include transport costs. For more information, please contact us by phone or email. Feel free to check our full offer on our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Trijų velenų elektromechaninis riedėjimo staklės

ESR-1300/2,5

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Three-Roller Electromechanical Bending Machine ESR-1300/2.5 with Asymmetrical Rolls is designed for manufacturing cylindrical and conical shells of varying diameters. This machine is intended for bending sheet metal up to 2.5 mm thick and 1300 mm wide, with a top roll diameter of 90 mm. The three-roll benders from this series are most popular due to their relatively simple yet highly functional construction.

Key features:

- Asymmetrical roll arrangement

- Bottom and top rolls driven by a gear system and chain drive from an electric motor

- Top roll rotates in both directions, equipped with a tilting mechanism

- Bottom and side rolls with height adjustment (manual adjustment)

- Capability for conical bending

- Foot pedal controller with emergency stop button

The chain drive transmits power from the electric motor to the rolls. The top roll can be opened, facilitating easy removal of finished workpieces. The folding roll is fitted with a lock to prevent accidental opening during operation.

Standard equipment:

- Operation manual in Polish

- CE Declaration

Technical Data

Model: CORMAK ESR-1300/2.5

Maximum working width [mm]: 1300

Maximum material thickness [mm]: 2.5

Roller diameter [mm]: 90

Fjdpfsmtwuyox Ab Soft

Motor power [kW]: 1.5

Dimensions (L x W x H) [mm]: 1800 x 640 x 1000

Machine weight [kg]: 600

NOTE: The nominal values for standard equipment are based on metals with a cold yield strength of 260 N/mm².

The quoted price is NET and does not include transport costs.

For further information, please contact us by phone or email. Please visit our website to see the full offer.

Mažas skelbimas

Siedlce

Siedlce

352 km

Radialinio gręžimo staklės

CORMAKRD1600x50

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Industrial radial drill press features a simple and rigid design, enabling a wide range of applications in hole processing such as drilling, reaming, counterboring, boring, and tapping.

Machine Description

- Drill press designed for drilling, tapping, and reaming;

- Minimized vibrations due to the special machine design—additional ribbing and reinforced cast iron construction;

- Oil-lubricated gearbox with ground and hardened gears made from high-quality steel alloy;

- Heavy weight and rigid construction ensure stability and vibration-free operation;

- Cubic worktable provides easy adaptation and clamping of the workpiece;

- Large-diameter, ground steel column;

- Ground base plate designed for machining larger components;

- Motorized height adjustment of the arm;

- Control panel located at the front of the drill for enhanced efficiency and ergonomics;

- Mechanical clamping of the arm and headstock;

- Boom arm height conveniently set via a lift motor;

- Hydraulically operated feed and spindle drive;

- Ground column surface allows for smooth, precise movement of the arm;

- Ground and hardened boom guideway;

- Drill equipped with manual headstock and column arm locking;

- Wide speed range ensures precise and rapid machining;

Technical Data

MAXIMUM DRILLING DIAMETER – 50 mm

DISTANCE SPINDLE AXIS TO COLUMN – 350 – 1600 mm

DISTANCE SPINDLE AXIS TO TABLE SURFACE – 320 – 1220 mm

SPINDLE QUILL TRAVEL – 390 mm

HORIZONTAL HEADSTOCK TRAVEL – 1250 mm

VERTICAL BOOM TRAVEL – 590 mm

SPINDLE TAPER – MT5

SPINDLE SPEED (16 steps) – 25 – 2000 rpm

FEED RANGE (16 steps) – 0.04–3.2 mm/rev

MAIN MOTOR POWER – 4.0/5.5 kW

LIFT MOTOR POWER – 1.5 kW

MACHINE DIMENSIONS – 2500x1070x2840 mm

Ffedpfx Aeg Rcd Uob Sot

WEIGHT – 3500 kg

The listed price is NET. Price does not include transport costs.

For further information, please contact us by phone or email. We invite you to view our full offer on our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Frezavimo / gręžimo staklės

CORMAKHK25L Vario

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, CORMAK HK25 VARIO is a compact milling and drilling machine designed for versatile applications. Ideal for both hobbyists and professionals, this machine offers not only compact dimensions but also exceptional functionality. Equipped with a MK3 spindle taper, it ensures machining stability and precision. The digital spindle speed readout allows for precise process control, guaranteeing excellent results.

Machine features:

- Digital speed readout

- Digital drilling depth readout

- Stepless speed adjustment

- Precisely mounted spindle bearings

Technical specifications:

DRILLING CAPACITY:

20 mm

FACE/END MILLING CAPACITY:

16 mm

END MILLING CAPACITY:

63 mm

SPINDLE TAPER:

MK3

SPINDLE QUILL TRAVEL:

50 mm

Fsdpfxotz Sxls Ab Sjft

NUMBER OF SPINDLE SPEEDS:

variable

SPINDLE SPEED RANGE:

50–2250 rpm

TABLE WORKING SURFACE:

700 x 180 mm

MAXIMUM LONGITUDINAL TABLE TRAVEL:

480 mm

MAXIMUM CROSS TABLE TRAVEL:

175 mm

MAXIMUM VERTICAL HEAD TRAVEL:

280 mm

NUMBER OF T-SLOTS:

3

T-SLOT DIMENSIONS:

T12 / 12 mm

MOTOR:

0.75 kW / 1 HP, 230V

DIMENSIONS:

980 x 600 x 1010 mm

WEIGHT:

110 / 125 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Frezavimo ir gręžimo staklės

CORMAKZX7045B1 + DRO

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, The ZX7045 B1 DRO milling and drilling machine is an advanced tool designed for precise metalworking. It excels in drilling, reaming, and enlarging holes up to 45/40 mm in cast iron, as well as tapping threads up to M12 mm. With a milling capacity of up to 80 mm width and keyway milling up to 22 mm, this machine ensures versatile use. The ZX7045 B1 DRO variant is distinguished by an automatic spindle feed, increasing operational efficiency. Additionally, it is equipped with digital readout for enhanced accuracy, and a cooling system to maintain optimal temperature during machining. This machine is ready for immediate use and available directly from stock. It is ideal for professionals seeking high quality and performance in metalworking.

Product Features:

- HEAVY, STURDY CAST IRON CONSTRUCTION

- AUTOMATIC SPINDLE FEED

- MILLING HEAD HEIGHT IS ADJUSTED ON THE SUPPORT, NOT THE COLUMN

- ADDITIONAL LIQUID COOLING

- MASSIVE CROSS TABLE WITH PRECISELY GROUND SURFACE

- DOVETAIL GUIDEWAYS

- QUIET OPERATION THANKS TO GROUND GEARS

- LEFT AND RIGHT SPINDLE ROTATION

- ROTATING HEAD +/- 90°

- ADJUSTABLE HEAD HEIGHT

- DIGITAL READOUT

- Optional base available

TECHNICAL SPECIFICATIONS:

DRILLING CAPACITY IN STEEL: 32 mm

DRILLING CAPACITY IN CAST IRON: 45 mm

FACE MILLING CUTTER DIAMETER: 80 mm

END MILL CUTTER DIAMETER: 28 mm

SPINDLE SPEEDS: 50, 95, 100, 180, 190, 355, 360, 655, 710, 1260, 1310, 2520 rpm (6/12)

SPINDLE TAPER: MT4

SPINDLE TRAVEL: 125 mm (AUTOMATIC FEED)

WORK TABLE DIMENSIONS: 820 mm x 240 mm

BASE DIMENSIONS: 580 x 600 mm

MAX SPINDLE TO TABLE DISTANCE: 445 mm

SPINDLE TO COLUMN DISTANCE: 260 mm

TRAVEL X/Y/Z AXIS: 515/175/430 mm

QUILL FEED RATE: 0.12; 0.18; 0.25 mm/rev

HEAD SWIVEL LEFT/RIGHT: 90°

MOTOR POWER: 1.8 kW (2.5 HP)

POWER SUPPLY: 400 V

WEIGHT: 350 kg

Available Accessories:

- Drill chuck arbor MK4/B18

- Digital readout

- Hand tools

- Drill chuck 3-16 mm/B18

- Reducing sleeve MK4/MK3

Ffjdpfx Aeud H H Ujb Sot

- Reducing sleeve MK3/MK2

- Operating manual in English

Mažas skelbimas

Siedlce

Siedlce

352 km

Frezavimo ir gręžimo staklės

CORMAKXZ 6350ZB

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Our XZ 6350ZB Milling-Drilling Machine guarantees both reliability and precision in a single solution. Featuring a straightforward, uncomplicated design, this machine ensures long-term, trouble-free operation. Equipped with both a horizontal spindle and a vertical head, the XZ 6350ZB is designed with versatility in mind.

Machine Features

- Vertical Head and Horizontal Spindle: The XZ 6350ZB is fitted with a vertical milling head as well as a horizontal spindle, making it suitable for a wide range of machining applications.

- ISO 40 Toolholder Taper: With an ISO 40 toolholder taper for stable and secure tool clamping, you are assured of precise machining results.

- Feed Drives and Rapid Traverse: The machine is equipped with power feeds in the X and Y axes, along with a rapid traverse function on the Z axis for precise setup and efficient operation.

- Extendable Vertical Spindle: The extendable vertical spindle allows for easier access to workpieces, making machine operation intuitive and user-friendly.

Ffodpsvxg T Aefx Ab Sst

- Mechanical Feeds and Automatic Threading: Three-stage mechanical feeds and the ability for automatic threading greatly expand the flexibility of machining processes.

- Swiveling Vertical Head and Extendable/Rotatable Upper Arm: The vertical head can swivel from 0° to 90°, while the upper arm can be both extended and rotated, further enhancing operational flexibility and precision for a variety of machining tasks.

Choose our XZ 6350ZB milling-drilling machine for a complete solution, including warranty, Polish-language manual, professional after-sales service, and convenient delivery. We are prepared to meet your machine tool needs, providing not only high quality but also comprehensive customer support.

Technical Specifications

WORKTABLE AREA: 1270 mm x 260 mm

TABLE TRAVEL X/Y/Z: 710 / 320 / 360 mm

NUMBER OF T-SLOTS: 5

T-SLOT SPACING: 50 mm

MAXIMUM TABLE LOAD: 200 kg

VERTICAL HEAD: Swiveling 90°

SPINDLE: Extendable L - 120 mm

SPINDLE TAPER: ISO 40

SPINDLE POWER FEED: 0.08-0.15-0.25 mm/rev

VERTICAL SPINDLE SPEED RANGE: 90 - 2,000 rpm

HORIZONTAL SPINDLE SPEED RANGE: 40 - 1,300 rpm

LONGITUDINAL FEED SPEED RANGE: 24 - 402 mm/min

CROSS FEED SPEED RANGE: 24 - 402 mm/min

RAPID TRAVERSE: Fast setup in Z axis

UPPER ARM EXTENSION: 460 mm

VERTICAL SPINDLE-COLUMN DISTANCE: 260 - 740 mm

VERTICAL SPINDLE-TABLE DISTANCE: 100 - 440 mm

HORIZONTAL SPINDLE-TABLE DISTANCE: 0 - 300 mm

DIGITAL READOUT: 3 axes

MAIN MOTOR POWER: 2.2 kW / 3 HP

OVERALL DIMENSIONS: 1520 x 1289 x 2150 mm

WEIGHT: 1,420 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Obliavimo staklės su spiraliniu kotu

CORMAKPT260Q

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, VERSION with the most powerful motor, total S6 power: 2.6 kW. A stronger motor ensures stable operation and easy machining of hard materials: hardwood requires more force for processing. A powerful motor handles this without any problem.

Latest version of the machine with an innovative table opening system:

• Competitive older machines feature 'butterfly-style' tables. Before each use, the infeed and outfeed tables must be calibrated against each other. Even minor differences can lead to material damage and undesired results.

• The new connected table solution allows for precise adjustment of both tables at the same time! Once set, the tables remain calibrated permanently. When changing the planing height, both tables move simultaneously.

• This solution not only saves time and increases operator convenience, but also improves planing accuracy by 30% compared to older designs. This is especially important when working with thinner materials.

Effortless conversion from jointer to thickness planer.

Switching from jointer to thickness planing function is very quick and simple. It only requires unlocking the eccentrics, lifting the tables, and repositioning the chip extraction cover.

Work precision:

• Smooth height adjustment of the tables with scale.

• Thickness planer table mounted centrally on a column, equipped with a handwheel for up and down adjustment.

• Aluminum tilting fence (700x150 mm) with scale bar, allowing precise angle adjustment from 90 to 45 degrees.

Technical specifications:

Cutterhead diameter: 75 mm

Cutterhead speed: 4000 rpm

Suction port diameter: 100 mm

Tilting fence angle: 90–45°

Number of knives: 3

Cutterhead length: 250 mm

Knife dimensions: 250x30x3 mm

Maximum jointer width: 250 mm

Maximum thicknessing width: 250 mm

Maximum planing height: 180 mm

Maximum thicknessing depth of cut: 3 mm

Maximum jointer depth of cut: 2.5 mm

Thicknesser feed speed: 6 m/min

Fence size: 700 x 150 mm

Machine dimensions (L x W): 1080 x 269 mm

Weight: 175 kg

Fsdpfxovxh A So Ab Soft

Total motor power: S1: 2.2 kW, S6: 2.6 kW

Power supply: 400V

Mažas skelbimas

Siedlce

Siedlce

352 km

Obliavimo staklės

CORMAKPT250 400V

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Planer-thicknessers, jointers in the Cormak range

Our shop offers a wide selection of professional, versatile planers that combine stable operation with high surface accuracy at competitive prices. Acquire a tool that will accelerate your production and improve the quality of your wooden products, even for hobby use in home workshops. Cormak stands for satisfaction guaranteed.

Construction and Operation of the Planer

Table: The thicknessing table is made from high-quality cast iron, ground and polished to a Ra 1.6 surface finish. Height adjustment is done via a large and ergonomic handwheel, which can be locked in place using an additional eccentric lever once the desired height is set.

Knives: The key element of the planer, installed above or below the table, are responsible for removing excess material from the wood surface. These knives are mounted on a rotating cutterblock or head.

Motor: The planer is powered by an electric motor that supplies the energy necessary to drive the cutterblock or planing head.

Cutterblock Guard: The guard can be freely adjusted for height, angle, and reach, allowing practical and user-friendly operation.

Feed Mechanism: The woodworking machine features drive and return rollers positioned very close to the cutterblock, enabling you to process even relatively short pieces. Feed roller drive is chain-based, ensuring slip-free operation and eliminating marking or gouging on the workpiece surface.

Guides: Guides ensure smooth and even movement of the workpiece. The angle guide can be smoothly set from 90° to 45°.

Stability: The heavy weight of the machine ensures high stability, providing safe, vibration-free operation, supported by anti-vibration feet.

Ease of Use: Adjustments are user-friendly, and switching from planing to thicknessing mode takes only a few seconds.

Technical Specifications for the Wood Thickness Planer:

Cutterblock diameter [mm]: 75

Cutterblock speed [rpm]: 4,000

Extraction port diameter [mm]: 100

Ffedpevxh Nrjfx Ab Sjt

Tilting fence angle [°]: 0 – 45

Number of knives: 3

Knife dimensions [mm]: 250 x 30 x 3

Maximum surfacing width [mm]: 254

Maximum thicknessing width [mm]: 254

Maximum planing height [mm]: 180

Maximum depth of cut (thicknesser) [mm]: 3

Maximum depth of cut (jointer) [mm]: 2.5

Thicknesser feed speed [m/min]: 6

Dimensions (L x W) [mm]: 1080 x 260

Gross weight [kg]: 152

Motor power: 2.6 kW

Power supply: 400V

Mažas skelbimas

Siedlce

Siedlce

352 km

Vamzdžių lenkimo staklės

CORMAKRBM40HV

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Electric tube and profile bending machine for bending pipes, profiles, rods, and flat bars depending on the installed bending rolls (bending dies). The machine is additionally equipped with a mechanical top roll pressure adjustment with a vernier scale. An ideal solution for bending arcs, circles, spirals, etc. Its substantial own weight ensures optimal stability during operation. Comes complete with a foot pedal for left/right drive control. Used in metalworking shops and construction sites. Maximum tube bending capacity up to 50 mm. The bender allows operation in both vertical and horizontal planes.

Machine features:

- Electric tube and profile bending machine. Allows work both vertically and horizontally.

- Equipped with a mechanically adjustable top roll pressure.

- Ideal for bending arcs, circles, and spirals.

- Bending radius set by means of a top-mounted pressure device with vernier scale.

- Applications: bending of profiles and pipes.

- Possibility of bending various profiles thanks to universal rolls.

- Very high own weight for optimal stability.

- Ground and hardened guide rolls on the sides.

- Bending rolls made from durable, hardened steel.

- Foot pedal operation.

- Operation in vertical and horizontal orientation.

- Left/right drive operation.

Standard equipment:

Ffedpfou Snm Iex Ab Sjt

- Side guide rolls

- Foot pedal

- Various sets of rolls

- Machine documentation in Polish

- CE Declaration

Technical data:

- Material: round tube [mm]: 50 x 2

- Material: rectangular profile [mm]: 50 x 50 x 2

- Material: round bar [mm]: 35

- Material: solid rectangular bar [mm]: 35 x 35

- Roll diameter [mm]: 40

- Motor power [kW]: S1 1.5 / S6 2.2

- Power supply: 3-phase, 400V

- Dimensions (L x W x H) [mm]: 900 x 850 x 1700

- Weight [kg]: 485

Mažas skelbimas

Siedlce

Siedlce

352 km

Apatinio veleno frezavimo staklės

CORMAKSH-30S PRECISA 230V/400V

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Funkcionalumas: visiškai funkcionalus, The robust and stable construction of the spindle moulder ensures high work quality. The set includes an interchangeable spindle with ER collets for shank cutters. The 30 mm extendable spindle rotates at four speeds. The thick, cast iron table provides optimal and precise operation. The upper part of the guard features a mechanism to hold the workpiece securely. The machine is equipped with a stable, heavy-duty base that absorbs vibrations.

Machine description

- Heavy, stable spindle moulder with interchangeable spindle and collet chuck!

- The milling table is made of ground cast iron, ensuring optimal gliding of the workpiece

- Included: workpiece holder, tiltable fence 60° left/right, workpiece stop

- REINFORCED, balanced spindle guarantees perfect milling during operations

- Standard height adjustment with scale!

- Interchangeable spindle with ER collet chuck, mitre fence, clamp, and fastening tool included

- Spindle speeds: 1400 / 4000 / 6000 / 9000 rpm

- The machine is equipped with anti-slip feet (vibration-free operation)

- Designed for machining the edges of straight workpieces as well as for creating decorative strips, grooves, tongues, tenons, and joints

- The machine meets all safety, instruction manual (DTR), and CE requirements

Technical data

Motor power S1: 2.2 kW

Voltage: 400 V

Ffedpfjvugf Dsx Ab Sjt

Table dimensions: 620 x 510 mm

Table height: 860 mm

Extraction port: 100 mm

Spindle stroke: 100 mm

Maximum clamping height: 105 mm

Table opening: 160 mm

Maximum tool diameter under table: 150 mm

Spindle rotation speed: 1400 / 4000 / 6000 / 9000 rpm

Spindle diameter: 30 mm

Gross weight: 126 kg

Overall dimensions: 640 x 660 x 1250 mm

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Siedlce

Siedlce

352 km

Vamzdžių ir profilių lenkimo staklės be įvorių

CORMAKBENDMASTER 70

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Precise and efficient industrial pipe bending machine for bending steel, copper, aluminium, and brass pipes. The option to select the optimal bending radius allows for high-quality results without material deformation. This bender is very user-friendly. Pipe benders are used for single-piece and small-batch production of parts in the automotive, furniture, architectural, and garden tool manufacturing industries. The main bending die is driven by a reduction gearbox and an electric motor. The machine operates in two modes: manual and semi-automatic. Its uncomplicated and robust design ensures long-lasting, trouble-free operation and guarantees ease of use.

Standard equipment:

- Digital angle readout

- The BENDMASTER machine is equipped with dies for pipes with diameters: 38.1; 48.3; 70 mm

Technical specifications:

- MAXIMUM DIAMETER OF BENT PIPE: 70x5 mm

- MAXIMUM DIMENSION OF BENT SQUARE PROFILE: 50x50x2 mm

- MAXIMUM BENDING ANGLE: 270°

- DIE ROTATIONAL SPEED DURING BENDING: 1.2 rpm

Fodpfx Abevugv Ae Soft

- DIE ROTATIONAL SPEED DURING RETURN: 2.4 rpm

- MAIN MOTOR POWER: 5 kW

- EXTERNAL DIMENSIONS: 1300x700x900 mm

- WEIGHT: 680 kg

For more information, feel free to contact us by phone or email. Please visit our website to view our full offer.

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAKTORNADO 400x1000

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, CORMAK 400 metal lathes are a newly improved version of the popular metalworking lathes. Among other upgrades, the tool post guard, spindle bearing system, and new digital readout have been enhanced. These machines are suitable for production plants, workshops, and tool rooms. They are ideal for both single-piece and small batch production.

NEW, IMPROVED MODEL!!!

high-quality, reinforced spindle bearing system

new guard system compliant with CE standards

latest model 2-axis digital readout

reinforced and modernized lathe base with tool drawers and pull-out chip tray

Machine Features

REINFORCED, RIBBED BEDWAY ENSURES MAXIMUM VIBRATION REDUCTION; ADDITIONALLY, THE BEDWAY IS PRECISION-GROUND AND HARDENED

2-AXIS DIGITAL READOUT AS STANDARD

OPTIMAL WORK RESULTS ENSURED BY LARGE SPINDLE BORE OF 52 mm

Fsdpoiz Tczefx Ab Soft

SUITABLE BEDWAY WIDTH PROVIDES STABLE AND PRECISE OPERATING CONDITIONS

LATHE EQUIPPED WITH HIGH-QUALITY, REINFORCED SPINDLE BEARING SYSTEM

EFFICIENT MACHINING THANKS TO TWO AUTOMATIC FEEDS AND EQUIPMENT WITH LEADSCREW AND FEED ROD

HARDENED GEARS IN SPINDLE GEARBOX

ADJUSTABLE OVERLOAD CLUTCH ON LEADSCREW

THREAD CUTTING ACROSS FULL RANGE WITHOUT NEED TO CHANGE GEARS IN THE QUICK-CHANGE GEARBOX

FEED SELECTOR LOCK: BY LEADSCREW OR FEED ROD

REMOVABLE GAP ALLOWS MACHINING OF OVERSIZED DIAMETER COMPONENTS

PULL-OUT CHIP TRAY AND TOOL DRAWERS FOR MORE EFFECTIVE AND EFFICIENT WORK

Technical Data

MAX. SWING OVER BED 400 mm

MAX. SWING OVER CROSS SLIDE 250 mm

MAX. SWING IN GAP 520 mm

TURNING LENGTH BETWEEN CENTRES 1000 mm

BEDWAY WIDTH 218 mm

SPINDLE NOSE CAMLOCK D5

SPINDLE TAPER MT6

SPINDLE BORE 52 mm

SPINDLE SPEED RANGE 65–1810 rpm

NUMBER OF SPINDLE SPEEDS 16 steps

LONGITUDINAL FEED RANGE (40) 0.053–1.291 mm/rev

CROSS FEED RANGE (40) 0.011–0.276 mm/rev

MAX. TOOL SIZE 25 x 25 mm

METRIC THREADS 0.4–7 mm

IMPERIAL THREADS 4–60 T.P.I.

MODULE THREADS (22) 0.4–3 mm

DIAMETRICAL PITCH (D.P.) THREADS (28) 8–84 D.P.

TAILSTOCK SLEEVE DIAMETER 50 mm

TAILSTOCK SLEEVE TRAVEL 110 mm

TAILSTOCK SLEEVE TAPER MT4

MOTOR POWER 2.2 kW

COOLANT PUMP POWER 0.1 kW

WEIGHT 640 kg

DIMENSIONS 2000 x 820 x 1650 mm

Standard Equipment

2-axis digital readout (DRO)

fixed steady rest

travelling steady rest

200 mm 3-jaw chuck

200 mm 4-jaw chuck

280 mm faceplate

2 x MT4 dead centre

MT6/MT4 reducing sleeve

keys

For more information, please visit our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Plazminio pjovimo staklės

CORMAKPW-1530 AST

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, The CNC plasma-oxygen gas cutting machine is a mobile device designed for shape-cutting components from sheet metal (in any shape). This machine is characterized by exceptional simplicity and ease of use. Our CNC cutter guarantees repeatability and high cutting accuracy (0.1 mm), allowing burned shapes to be forwarded directly to the next stage of production.

Why choose this machine?

- Dual cutting capabilities: plasma or flame (2 in 1)

- Compact dimensions allow installation anywhere

- Voltage-based THC height controller

- Precise torch alignment

Fodei Apn Uepfx Ab Seft

- Highly accurate cutting with no need for post-processing

- Sheet metal detection system

- Convenient operator panel

- Intuitive operation

- Capable of both cutting and gouging steel

- Operator training available at buyer’s or seller’s site

- Library of standard geometric shapes

Features and equipment:

- Working area: 1500 x 3000 mm

- Y-axis clearance: 140 mm

- Cutting accuracy: +/- 0.1 mm/m

- Weight: 450 kg

- Sturdy and stable frame design

- Gas mixer

- Gas torch

- Voltage height controller

- Torch height adjustment system

- Torch height and stabilization sensor

- FastCAM software (Polish language, licensed)

- USB port, internal and external memory

- User-friendly interface – easy for users with no prior FastCAM experience

- Import drawings in *.txt format from any CAD software (AutoCAD, SolidWorks, etc.)

- MACRO – library of standard geometric shapes for quick figure creation without drawing

- NESTING – automatic layout optimization on the sheet

- DEMO – displays work cycle/path without activating the plasma or oxygen source

Cutter sold without table.

Listed price is net. Transport costs not included.

For more information, please contact us by phone or email. Please visit our website to view our full offer.

Mažas skelbimas

Siedlce

Siedlce

352 km

CNC tekinimo staklės

CORMAKCNC CKT 320x750 Hydraulic SAH6

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, The lathe is ideally suited for efficient and precise machining of metal parts as well as other materials. The machine features capabilities for machining internal and external cylindrical surfaces, face surfaces, tapered, semi-circular surfaces, and threading. The bed is a solid cast iron construction, resistant to vibrations. The guides are induction-hardened and ground.

Technical data

TURNING DIAMETER OVER BED 320 mm

TURNING DIAMETER OVER CARRIAGE 160 mm

DISTANCE BETWEEN CENTERS 750 mm

SPINDLE SPEED 100-2500 rpm

SPINDLE BORE 46 mm

SPINDLE NOSE MT5

NUMBER OF TOOLS 6

TOOL SIZE 16x16 mm

MAXIMUM DIAMETER OF WORKPIECE THROUGH SPINDLE 44 mm

TAILSTOCK QUILL MT3

MAXIMUM TAILSTOCK TRAVEL 100 mm

MOTOR POWER 3 kW

DIMENSIONS 2370 x 1420 x 2000 mm

NET WEIGHT 950/1300 kg

Fedpfx Asi Apg Ujb Soft

Available equipment

SINUMERIK 808D control unit in Polish

SIEMENS servo drives

3-jaw hydraulic lathe chuck

6-position turret head

Set of soft jaws

Hydraulic tailstock

Cooling system

Automatic lubrication system for gears and guides

24V halogen lighting

Technical documentation in Polish

CE declaration

The listed price is NET (excluding VAT). Price does not include transport costs.

For more information, please contact us by phone or email. We also invite you to visit our website to view our full offer.

Palengviname jums paiešką: "pneumatiniai įsriegimo staklės"

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota Pneumatiniai Įsriegimo Staklės (48 366)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- Automatinis Šlifavimo Staklės

- Cnc Plazminės Pjovimo Staklės

- Kampo Pjovimo Staklės

- Kniedijimo Staklės

- Lakštų Lenkimo Staklės

- Lakštų Tiesinimo Staklės

- Leit Verpstės Tekinimo Staklės

- Lentelės Pjaustymo Staklės

- Liepsnos Pjovimo Staklės

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo