Didelio greičio keturių pusių obliavimo staklėsLEDINEK

SUPERLES 300 5V-S150

Didelio greičio keturių pusių obliavimo staklės

LEDINEK

SUPERLES 300 5V-S150

Gamybos metai

2004

Sąlyga

Naudotas

Vieta

Roches-Prémarie-Andillé

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Didelio greičio keturių pusių obliavimo staklės

- Gamintojas:

- LEDINEK

- Modelis:

- SUPERLES 300 5V-S150

- Gamybos metai:

- 2004

- Sąlyga:

- labai geros būklės (naudotas)

Kaina ir vieta

- Vieta:

- ZA du val de bocq, 86340 Roches Premarie, France

Skambinti

Techniniai duomenys

- Darbinis plotis:

- 300 mm

- Obliavimo aukštis:

- 120 mm

- Ašies skersmuo:

- 50 mm

- Obliavimo plotis:

- 300 mm

- Darbinio aukščio:

- 1 000 mm

- Bendras plotis:

- 2 800 mm

- Bendras aukštis:

- 2 400 mm

- Bendras ilgis:

- 3 800 mm

- Bendras svoris:

- 13 000 kg

- Padavimo variklio galia:

- 24 000 W

- Veleno greitis (min.):

- 5 500 aps./min

- Sukimosi greitis (maks.):

- 6 000 aps./min

- Sukimosi greitis (min.):

- 5 500 aps./min

- Aukščio reguliavimo tipas:

- elektrinis

- Obliaus veleno skersmuo:

- 205 mm

- Ruošinio aukštis (maks.):

- 120 mm

- Ruošinio plotis (maks.):

- 330 mm

- Įėjimo įtampa:

- 400 V

- Įrankio skersmuo:

- 205 mm

- Ašies skaičius:

- 5

- Galia:

- 154 kW (209,38 AG)

- Stalo plotis:

- 330 mm

Pasiūlymo informacija

- Sąrašo ID:

- A19590826

- Naujinta paskutinį kartą:

- Data 2025.07.24

Aprašymas

4-Sided Moulder for Lamellas 300 x 120 mm

Adjustable feed speed from 30 to 150 m/min.

Equipment:

- 2 horizontal top and bottom cutter blocks, Z=10

- 2 vertical right and left cutter blocks, Z=10

- All equipped with jointing devices

Technical specifications:

- Horizontal spindle speed: 5,500 rpm

- Vertical spindle speed: 6,000 rpm

- Vertical spindle diameter: 50 mm

- Vertical spindle clamping length: max. 185 mm

Tool diameters:

- Horizontal cutter blocks: 205 mm

- Vertical spindle tool heads: 160 – 205 mm

Cutter blocks:

- Planer and thicknessing spindles with following cutter blocks:

- 2 x Planer heads 205 x 330 mm, Z=10, screw clamping

- Planer knives for lamellas: 3 x 35 x 330

- 2 x Hydraulic planer heads 190 x 130 mm, Z=10, screw clamping

- Planer knives for lamellas: 3 x 35 x 130

- Weight: approx. 13,000 kg

- Machine dimensions (L x W x H): approx. 3,800 x 2,800 x 2,400 mm

- Installed power: 154 kW

Additional units

Bottom Grooving Saw

This unit is used for machining balance grooves on the bottom side of processed wood lamellas with a width over 200 mm. The saw blade is mounted directly onto a flat motor using a flange. Horizontal movement of the grooving saw is about 150 mm via pneumatic cylinder (movement between boards; triggered by a movable spot sensor). Groove position adjustment is manual; the traverse distance is indicated by a counter. Vertical movement is approximately 30 mm via pneumatic cylinder (allows rapid changeover during machining between lamellas with/without groove). End stop (groove depth) is adjusted manually; position is shown on the counter. Lamellas must be entered into the machine individually, piece by piece (not pushed consecutively).

Technical data:

- Grooving saw motor power: 15 kW

- Saw blade speed: 5,000 rpm

Ihsdpfx Aowz Nzmjf Ist

- Arbor diameter: 40 mm

- Max. cutting depth: 50 mm

- Tool diameter: 300 x 4 mm

- Extraction hood connection diameters: 120 mm

- Additional feed rollers: one above, Ø240 mm, one below Ø240 mm, toothed and hardened chrome. Delivery includes saw blade.

- Working range for grooving saw: from 37.5 up to 225 mm

Motorised Lateral Infeed Roller

Pneumatically suspended. Motorized width adjustment via control panel push buttons. (If spindle positioning control is set up as an option, the lateral pressure roller can be adjusted from the control panel). Adjusted width is indicated on a SIKO counter.

- Roller diameter: 190 mm

- Roller height: 40 mm

Automatic Knife Jointing Device

The automatic knife jointing unit is fixed in place. Actuation is manual.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Adjustable feed speed from 30 to 150 m/min.

Equipment:

- 2 horizontal top and bottom cutter blocks, Z=10

- 2 vertical right and left cutter blocks, Z=10

- All equipped with jointing devices

Technical specifications:

- Horizontal spindle speed: 5,500 rpm

- Vertical spindle speed: 6,000 rpm

- Vertical spindle diameter: 50 mm

- Vertical spindle clamping length: max. 185 mm

Tool diameters:

- Horizontal cutter blocks: 205 mm

- Vertical spindle tool heads: 160 – 205 mm

Cutter blocks:

- Planer and thicknessing spindles with following cutter blocks:

- 2 x Planer heads 205 x 330 mm, Z=10, screw clamping

- Planer knives for lamellas: 3 x 35 x 330

- 2 x Hydraulic planer heads 190 x 130 mm, Z=10, screw clamping

- Planer knives for lamellas: 3 x 35 x 130

- Weight: approx. 13,000 kg

- Machine dimensions (L x W x H): approx. 3,800 x 2,800 x 2,400 mm

- Installed power: 154 kW

Additional units

Bottom Grooving Saw

This unit is used for machining balance grooves on the bottom side of processed wood lamellas with a width over 200 mm. The saw blade is mounted directly onto a flat motor using a flange. Horizontal movement of the grooving saw is about 150 mm via pneumatic cylinder (movement between boards; triggered by a movable spot sensor). Groove position adjustment is manual; the traverse distance is indicated by a counter. Vertical movement is approximately 30 mm via pneumatic cylinder (allows rapid changeover during machining between lamellas with/without groove). End stop (groove depth) is adjusted manually; position is shown on the counter. Lamellas must be entered into the machine individually, piece by piece (not pushed consecutively).

Technical data:

- Grooving saw motor power: 15 kW

- Saw blade speed: 5,000 rpm

Ihsdpfx Aowz Nzmjf Ist

- Arbor diameter: 40 mm

- Max. cutting depth: 50 mm

- Tool diameter: 300 x 4 mm

- Extraction hood connection diameters: 120 mm

- Additional feed rollers: one above, Ø240 mm, one below Ø240 mm, toothed and hardened chrome. Delivery includes saw blade.

- Working range for grooving saw: from 37.5 up to 225 mm

Motorised Lateral Infeed Roller

Pneumatically suspended. Motorized width adjustment via control panel push buttons. (If spindle positioning control is set up as an option, the lateral pressure roller can be adjusted from the control panel). Adjusted width is indicated on a SIKO counter.

- Roller diameter: 190 mm

- Roller height: 40 mm

Automatic Knife Jointing Device

The automatic knife jointing unit is fixed in place. Actuation is manual.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Dokumentai

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+33 6 09 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Italija

Italija

1 282 km

Dailidės

HundeggerK2

HundeggerK2

Mažas skelbimas

Zabok

Zabok

1 164 km

REGISTRACIJA

Mažas skelbimas

Schwanberg

Schwanberg

1 115 km

Platus juostinis šlifuoklis

SACrte 1000

SACrte 1000

Mažas skelbimas

Engen

Engen

1 323 km

Medienos smulkintuvas

VecoplanVTH 250 (250 x 650)

VecoplanVTH 250 (250 x 650)

Mažas skelbimas

Rödermark

Rödermark

1 168 km

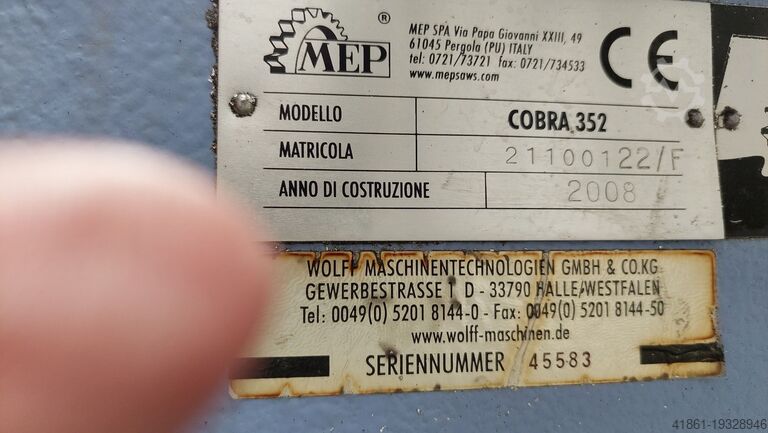

Aliuminio kampinis pjūklas

MEPCobra 352

MEPCobra 352

Mažas skelbimas

Geiselwind

Geiselwind

1 087 km

Dvigubas sijonas ir pjovimo diskinis pjūklas

EWDDK 90 - 1000 / RET / KB / ASV

EWDDK 90 - 1000 / RET / KB / ASV

Mažas skelbimas

Grevesmühlen

Grevesmühlen

833 km

Juostinis pjūklas

Braun CanaliTB 1100 Unimaster

Braun CanaliTB 1100 Unimaster

Mažas skelbimas

Elbląg

Elbląg

312 km

Obliavimo staklės ir frezavimo staklės

WeinigU23

WeinigU23

Mažas skelbimas

Gusselby

Gusselby

718 km

Pilna didelių rąstų pjovimo linija

AKE,Söderhamns, Remill, Catech, Ari

AKE,Söderhamns, Remill, Catech, Ari

Mažas skelbimas

Wysoka

Wysoka

495 km

Plonapjūvė juostinė staklė

WintersteigerDSG SONIC

WintersteigerDSG SONIC

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida