Klasifikuojantis malūnasHosokawa Alpine

ZPS 315

Klasifikuojantis malūnas

Hosokawa Alpine

ZPS 315

Gamybos metai

1996

Sąlyga

Naudotas

Vieta

Augsburg

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Klasifikuojantis malūnas

- Gamintojas:

- Hosokawa Alpine

- Modelis:

- ZPS 315

- Gamybos metai:

- 1996

- Sąlyga:

- visiškai atnaujintas (naudotas)

Kaina ir vieta

- Vieta:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A8823965

- Naujinta paskutinį kartą:

- Data 2025.02.10

Aprašymas

Used Hosokawa Alpine Zirkoplex ZPS 315 Classifier Mill

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusively uses original components

Original manufacturer’s warranty

Guaranteed supply of spare parts from the manufacturer

Reduced delivery time

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine can be customized to your specific requirements

Possibility of supplying all required peripherals or adapting to your existing production plant

We are also interested in buying back unused HOSOKAWA ALPINE equipment

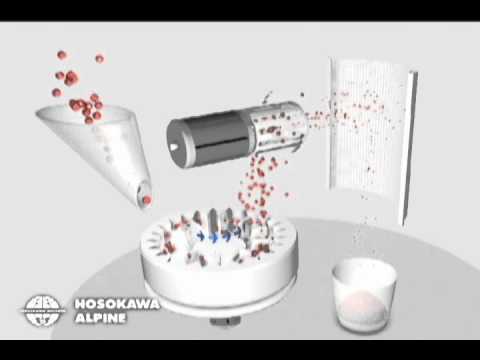

The Hosokawa Alpine Zirkoplex ZPS classifier impact mill is ideal for the fine grinding of various dry materials, offering precise control of cut point or maximum particle size, thanks to its integrated classifier wheel design. It can be used to micronize a wide range of products across different industries where fine particle size reduction is required, such as the mineral, chemical, food, and pharmaceutical industries. Grinding occurs in the lower section of the mill, where a rotating plate equipped with grinding tools (hammers or pins) impacts and propels the material against the internal grinding track (liner) for size reduction. Within the same chamber, the airflow carries fine particles to the classifier wheel, where oversized grains are rejected and returned for further grinding, while the fines pass through for subsequent processing, typically filtration.

Due to the necessary process air, a minimal temperature increase during grinding is to be expected compared to other granulation technologies. The final particle size distribution can easily be adjusted by modifying parameters such as the rotor speed, classifier wheel speed, air volume, feed rate, etc.

Construction material: Stainless steel for product-contact parts

No wear protection

Not equipped with explosion protection (NPSR), not ATEX

Scope of supply:

Dcodokqlf Sspfx Admon

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and installation base

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusively uses original components

Original manufacturer’s warranty

Guaranteed supply of spare parts from the manufacturer

Reduced delivery time

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine can be customized to your specific requirements

Possibility of supplying all required peripherals or adapting to your existing production plant

We are also interested in buying back unused HOSOKAWA ALPINE equipment

The Hosokawa Alpine Zirkoplex ZPS classifier impact mill is ideal for the fine grinding of various dry materials, offering precise control of cut point or maximum particle size, thanks to its integrated classifier wheel design. It can be used to micronize a wide range of products across different industries where fine particle size reduction is required, such as the mineral, chemical, food, and pharmaceutical industries. Grinding occurs in the lower section of the mill, where a rotating plate equipped with grinding tools (hammers or pins) impacts and propels the material against the internal grinding track (liner) for size reduction. Within the same chamber, the airflow carries fine particles to the classifier wheel, where oversized grains are rejected and returned for further grinding, while the fines pass through for subsequent processing, typically filtration.

Due to the necessary process air, a minimal temperature increase during grinding is to be expected compared to other granulation technologies. The final particle size distribution can easily be adjusted by modifying parameters such as the rotor speed, classifier wheel speed, air volume, feed rate, etc.

Construction material: Stainless steel for product-contact parts

No wear protection

Not equipped with explosion protection (NPSR), not ATEX

Scope of supply:

Dcodokqlf Sspfx Admon

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and installation base

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2019

Pateikti užklausą

Telefonas & Faksas

+49 821 2... skelbimai

Šie skelbimai taip pat gali jus sudominti.

mažas skelbimas

Augsburg

Augsburg

1 171 km

Klasifikuojantis malūnas

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

mažas skelbimas

Arnsberg

Arnsberg

1 135 km

Klasifikatoriaus malūnas

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida