Hidraulinis presasHidrobrasil

400 Tonnen Viersäulenpresse

Hidraulinis presas

Hidrobrasil

400 Tonnen Viersäulenpresse

Gamybos metai

2020

Sąlyga

parodomoji mašina

Vieta

Gelsenkirchen

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Hidraulinis presas

- Gamintojas:

- Hidrobrasil

- Modelis:

- 400 Tonnen Viersäulenpresse

- Gamybos metai:

- 2020

- Sąlyga:

- beveik kaip naujas (parodų įrenginys)

Kaina ir vieta

- Vieta:

- Hertener Strasse 108, 45892 Gelsenkirchen, Deutschland

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A6102226

- Nuorodos Nr.:

- HB 2021-A-114- 4

- Naujinta paskutinį kartą:

- Data 2025.03.27

Aprašymas

Hydraulic 400-ton Column Press

Suitable for continuous shift operation, with the following basic specifications:

a) Closing speed: 100 – 450 mm/sec

b) Opening speed: 50 – 250 mm/sec (adjustable via touchscreen)

c) Pressing speed: 5 – 60 mm/sec (adjustable via touchscreen)

d) Piston accumulator with approx. 4 nitrogen cylinders

e) Table size (clamping surface): 2700 x 1700 mm (viewed from the front, between the columns)

f) Total table size: 3400 x 1700 mm

g) 28 mm T-slots according to customer specifications

Bjdjg Iihwopfx Adwsld

h) Table, ram, and press head are stress-relieved annealed.

i) Column diameter: 250 mm

j) Ram size: 3400 x 1700 mm (clamping surface 2700 x 1700 mm)

k) Overall machine dimensions approx. 3900 x 2200 (footprint) x 5700 mm height

l) Oil temperature monitoring (adjustable via touchscreen)

m) Automatic lubrication (adjustable via touchscreen)

n) Free positioning of the ram (adjustable via touchscreen)

o) KEYENCE light barriers, 14 mm, on front and rear sides

p) Oil circulation cooling (adjustable via touchscreen)

q) Pressure-holding valve 0 to 600 sec. (adjustable via touchscreen)

r) Table plate size 3400 x 1700 mm, precision milled

s) Laterally monitored doors, 1200 mm high, 1000 mm wide

t) RITTAL control cabinet, 2200 mm wide, up to 20 m distance from the press

u) Pressure adjustment from 50 to 400 tons (adjustable via touchscreen)

v) Stroke limitation selectable by pressure or position

w) Programmable operation, setup mode, single stroke + continuous stroke (adjustable via rotary switch)

x) Swiveling control console with 15-inch touchscreen monitor

y) Two-hand operation on both sides

z) Prepared for automatic material feed (SIEMENS S7 1500)

aa) Machine frame primed and painted

bb) Installation, commissioning, and training available at additional cost

The hydraulics of the presses we offer are configured exclusively with BOSCH-REXROTH/Parker/HAWE components. Only (SIEMENS) components that are readily available in Germany are used in the control cabinet. Safety technology is supplied entirely by SICK, except for the light barriers.

The control system is provided by SIEMENS (S7 1500), including the 15-inch touchscreen monitor. The delivery also includes the SIEMENS remote maintenance unit SECOME Ethernet.

SPECIAL FEATURE: Our design with two press cylinders and the piston accumulator allows full performance to be achieved with a main motor of just 90 kW.

Technical details are provided below in 1.3.

Technical Specifications

Design

Press design: Column press

Thermal neutral: 80 – 120°C

Number of operating sides: 2

Forces

Pressing force max.: 4,000 kN

Free pull-off force max.: 600 kN

Pressure build-up time (closed tool steel to steel): Max. 2 sec

Dimensions – Minimum intended tool height: 600 mm

Maximum opening width: 1600 mm

Stroke and min. opening: 1000/600 mm

Table height above floor: 820 mm

Height above floor (overall height): approx. 5700 mm

Hall height min.: 7000 mm

Parallelism deviation at 20°C: +/- 0.1 mm

Deflection (determined at max. closing force with 70% occupancy): ≤ 0.17 mm/m

Weight

Total weight of the press without operating materials: approx. 52 t

Speeds (see attached cycle diagram)

Rapid-closing: 100 – 450 mm/s

Pressing speed at F max.: [data continues]

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Suitable for continuous shift operation, with the following basic specifications:

a) Closing speed: 100 – 450 mm/sec

b) Opening speed: 50 – 250 mm/sec (adjustable via touchscreen)

c) Pressing speed: 5 – 60 mm/sec (adjustable via touchscreen)

d) Piston accumulator with approx. 4 nitrogen cylinders

e) Table size (clamping surface): 2700 x 1700 mm (viewed from the front, between the columns)

f) Total table size: 3400 x 1700 mm

g) 28 mm T-slots according to customer specifications

Bjdjg Iihwopfx Adwsld

h) Table, ram, and press head are stress-relieved annealed.

i) Column diameter: 250 mm

j) Ram size: 3400 x 1700 mm (clamping surface 2700 x 1700 mm)

k) Overall machine dimensions approx. 3900 x 2200 (footprint) x 5700 mm height

l) Oil temperature monitoring (adjustable via touchscreen)

m) Automatic lubrication (adjustable via touchscreen)

n) Free positioning of the ram (adjustable via touchscreen)

o) KEYENCE light barriers, 14 mm, on front and rear sides

p) Oil circulation cooling (adjustable via touchscreen)

q) Pressure-holding valve 0 to 600 sec. (adjustable via touchscreen)

r) Table plate size 3400 x 1700 mm, precision milled

s) Laterally monitored doors, 1200 mm high, 1000 mm wide

t) RITTAL control cabinet, 2200 mm wide, up to 20 m distance from the press

u) Pressure adjustment from 50 to 400 tons (adjustable via touchscreen)

v) Stroke limitation selectable by pressure or position

w) Programmable operation, setup mode, single stroke + continuous stroke (adjustable via rotary switch)

x) Swiveling control console with 15-inch touchscreen monitor

y) Two-hand operation on both sides

z) Prepared for automatic material feed (SIEMENS S7 1500)

aa) Machine frame primed and painted

bb) Installation, commissioning, and training available at additional cost

The hydraulics of the presses we offer are configured exclusively with BOSCH-REXROTH/Parker/HAWE components. Only (SIEMENS) components that are readily available in Germany are used in the control cabinet. Safety technology is supplied entirely by SICK, except for the light barriers.

The control system is provided by SIEMENS (S7 1500), including the 15-inch touchscreen monitor. The delivery also includes the SIEMENS remote maintenance unit SECOME Ethernet.

SPECIAL FEATURE: Our design with two press cylinders and the piston accumulator allows full performance to be achieved with a main motor of just 90 kW.

Technical details are provided below in 1.3.

Technical Specifications

Design

Press design: Column press

Thermal neutral: 80 – 120°C

Number of operating sides: 2

Forces

Pressing force max.: 4,000 kN

Free pull-off force max.: 600 kN

Pressure build-up time (closed tool steel to steel): Max. 2 sec

Dimensions – Minimum intended tool height: 600 mm

Maximum opening width: 1600 mm

Stroke and min. opening: 1000/600 mm

Table height above floor: 820 mm

Height above floor (overall height): approx. 5700 mm

Hall height min.: 7000 mm

Parallelism deviation at 20°C: +/- 0.1 mm

Deflection (determined at max. closing force with 70% occupancy): ≤ 0.17 mm/m

Weight

Total weight of the press without operating materials: approx. 52 t

Speeds (see attached cycle diagram)

Rapid-closing: 100 – 450 mm/s

Pressing speed at F max.: [data continues]

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+49 209 9... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Gelsenkirchen

Gelsenkirchen

1 179 km

Hidraulinis presas

HidrobrasilDoppelständerpresse 400 Tonnen

HidrobrasilDoppelständerpresse 400 Tonnen

Mažas skelbimas

Vokietija

Vokietija

999 km

Hidraulinis presas

ISGEC300t - 2500t

ISGEC300t - 2500t

Mažas skelbimas

Birmingham

Birmingham

1 709 km

Vandens slėgis

SchulerEB 2-500

SchulerEB 2-500

Mažas skelbimas

Wermelskirchen

Wermelskirchen

1 194 km

Hidraulinis presas

Hans SchoenUTE FF 300/80

Hans SchoenUTE FF 300/80

Mažas skelbimas

Danija

Danija

908 km

NAUDOTA CNC TEKINIMO STAKLĖS MAZAK, MODELIS SQT 250 M-1000 L

MAZAKSQT 250 M-1000L

MAZAKSQT 250 M-1000L

Mažas skelbimas

Vaterstetten

Vaterstetten

1 140 km

Įpurškimo liejimo mašina

KraussMaffei Technologies GmbHKM 160 / 750 PA G01

KraussMaffei Technologies GmbHKM 160 / 750 PA G01

Mažas skelbimas

Metzingen

Metzingen

1 242 km

Siūlų valcavimo mašina

PROFIROLL BAD DUEBENROLLEX

PROFIROLL BAD DUEBENROLLEX

Mažas skelbimas

Birmingham

Birmingham

1 709 km

Hidraulinis piešimo presas

SMGHZPU

SMGHZPU

Mažas skelbimas

Korschenbroich

Korschenbroich

1 233 km

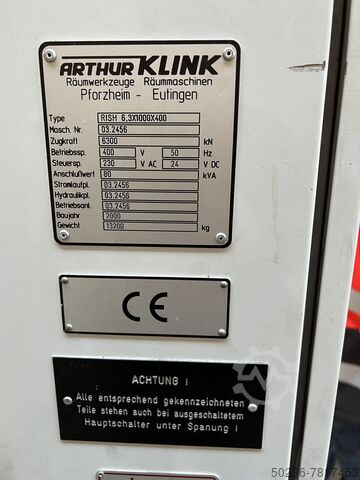

CNC vidinio praplėtimo staklės

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

Mažas skelbimas

Ciriè

Ciriè

1 596 km

Dviejų kolonų hidraulinis presas

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida