Didelio greičio granuliatoriusZERMA

GST 250/300

Didelio greičio granuliatorius

ZERMA

GST 250/300

Pradinė kaina neįskaitant PVM

16 200 €

Gamybos metai

2025

Sąlyga

Naujas

Vieta

Buchholz in der Nordheide

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Didelio greičio granuliatorius

- Gamintojas:

- ZERMA

- Modelis:

- GST 250/300

- Gamybos metai:

- 2025

- Sąlyga:

- naujas

Kaina ir vieta

Pradinė kaina neįskaitant PVM

16 200 €

- Vieta:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A13548235

- Naujinta paskutinį kartą:

- Data 2025.05.03

Aprašymas

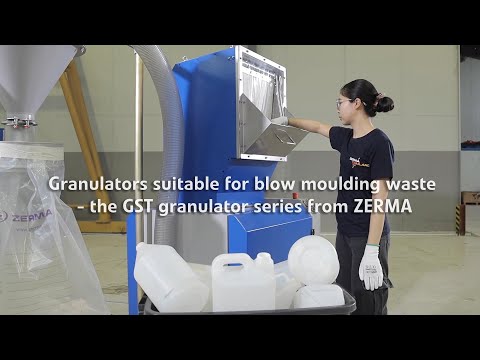

Size reduction of large-volume blow-molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been combined, with particular emphasis on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives are adjustable outside of the machine, thus reducing downtime during maintenance.

The strongly tangential, curved rear wall of the cutting chamber in combination with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages. These compact granulators are suitable for use in blow molding operations. They are ideal for recycling, e.g., voluminous items such as bottles, canisters, and crates. Thanks to the low feeding height, the machines can be easily loaded manually or with a small conveyor belt. The low noise emissions and small footprint make the granulator a perfect solution for in-line size reduction.

Optional rear wall with elevated stator knife, M Version:

The feed method with an elevated stator knife is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the less aggressive rotor, high-quality regrind is achieved regardless of the material type or shape, such as injection molded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control system and operator console not only comply with all relevant safety regulations, but can also be adapted to specific requirements. In addition, peripheral devices such as feed conveyors, metal detection, and discharge systems can be seamlessly integrated into the machine’s control system. For enhanced efficiency, an optional intelligent energy saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the upstream machine status.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Nodpjp Sr Ansfx Af Nswb

Rotor diameter (mm): 250

Rotor width (mm): 300

Drive (kW): 7.5

Number of rotor knives: 3 x 1

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 950

Feed opening (mm): 380 x 300

Feed opening option for M Version (mm): 295 x 300

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

In a compact redesign, the best features of the proven GST and GSC series have been combined, with particular emphasis on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives are adjustable outside of the machine, thus reducing downtime during maintenance.

The strongly tangential, curved rear wall of the cutting chamber in combination with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages. These compact granulators are suitable for use in blow molding operations. They are ideal for recycling, e.g., voluminous items such as bottles, canisters, and crates. Thanks to the low feeding height, the machines can be easily loaded manually or with a small conveyor belt. The low noise emissions and small footprint make the granulator a perfect solution for in-line size reduction.

Optional rear wall with elevated stator knife, M Version:

The feed method with an elevated stator knife is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the less aggressive rotor, high-quality regrind is achieved regardless of the material type or shape, such as injection molded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control system and operator console not only comply with all relevant safety regulations, but can also be adapted to specific requirements. In addition, peripheral devices such as feed conveyors, metal detection, and discharge systems can be seamlessly integrated into the machine’s control system. For enhanced efficiency, an optional intelligent energy saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the upstream machine status.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Nodpjp Sr Ansfx Af Nswb

Rotor diameter (mm): 250

Rotor width (mm): 300

Drive (kW): 7.5

Number of rotor knives: 3 x 1

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 950

Feed opening (mm): 380 x 300

Feed opening option for M Version (mm): 295 x 300

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2023

Pateikti užklausą

Telefonas & Faksas

+49 4181 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Düsseldorf

Düsseldorf

1 218 km

Tiesinimo presas Hidraulinis presas 150 tonų

TigermetalWerkstattpresse 150 Tonnen WH150

TigermetalWerkstattpresse 150 Tonnen WH150

Mažas skelbimas

Sinsheim

Sinsheim

1 213 km

Pjovimo staklės

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

Mažas skelbimas

Breginj

Breginj

1 232 km

Automatinės strypų tekinimo staklės

CitizenL20

CitizenL20

Mažas skelbimas

Suffolk

Suffolk

1 551 km

Vežimėliai ir padėklai 1300 mm skersmens retortoms

SteriflowRetort trolleys and trays

SteriflowRetort trolleys and trays

Mažas skelbimas

Radeberg

Radeberg

802 km

Sraigtiniai kūginiai reduktoriai Pramoniniai reduktoriai

ASUG Penig FlenderTGL 21815 10LA1 280/400x80

ASUG Penig FlenderTGL 21815 10LA1 280/400x80

Mažas skelbimas

Soerendonk

Soerendonk

1 289 km

Reduktorius / pavarų dėžė

Flender / SiemensK2S-2,5

Flender / SiemensK2S-2,5

Mažas skelbimas

Rzeszów

Rzeszów

585 km

Kepyklų vežimėliai, bandymų vežimėliai

58x78

58x78

Mažas skelbimas

Hessisch Lichtenau

Hessisch Lichtenau

1 040 km

ISBM linija = įpurškimo tempiamojo pūtimo formavimas; Vienkartinių PET butelių tempiamojo pūtimo maš

ETEK / GF-IndustriesSupra 800 sv 1

ETEK / GF-IndustriesSupra 800 sv 1

Mažas skelbimas

Turkija

Turkija

2 028 km

CM10 KABELIŲ PERDIRBIMO MAŠINA

CABMILLCM10

CABMILLCM10

Mažas skelbimas

Oradea

Oradea

914 km

3D skaitytuvas

Dental WingsDW-5-140

Dental WingsDW-5-140

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida