Depanų išėmimas / PCB apdirbimasSystemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Depanų išėmimas / PCB apdirbimas

Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Gamybos metai

2026

Sąlyga

Naujas

Vieta

Kronberg im Taunus

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Depanų išėmimas / PCB apdirbimas

- Gamintojas:

- Systemtechnik Hölzer GmbH

- Modelis:

- Nutzentrenner LOW 4233 XL RD

- Gamybos metai:

- 2026

- Sąlyga:

- naujas

- Funkcionalumas:

- visiškai funkcionalus

Kaina ir vieta

- Vieta:

- Westerbachstraße 4, 61476 Kronberg im Taunus, Deutschland

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A18369436

- Nuorodos Nr.:

- LOW4233 RD XL Leiterplatten Nutzentrenner

- Naujinta paskutinį kartą:

- Data 2026.01.26

Aprašymas

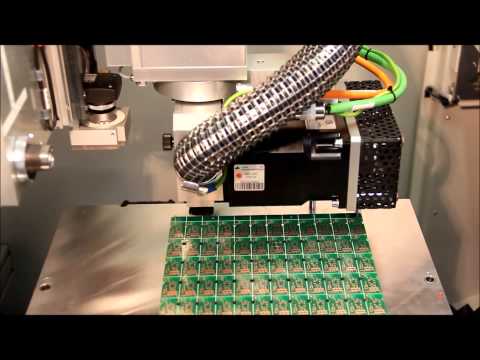

Semi-automatic Depaneling / Base Machine with Parallel Shuttle

The dynamic depaneling machine LOW 4322 XL is specifically designed for medium to high product volumes, meeting increasing requirements in the production process. PCB panels of various materials are separated using low-dust, low-stress sawing and milling techniques, ensuring maximum product flexibility, precision, and throughput. High-dynamic linear motor axes, tools, and grippers meet the highest quality standards, ensuring the depaneler offers long service life and reliability.

Semi-automatic Depaneling – Demand-driven Solutions

The LOW 4322 XL depaneler enables fast product changeover while maintaining short separating and handling times. Loading PCB panels is carried out via a parallel shuttle, and securing is done with pin clamping technology, optionally combined with vacuum suction when required.

Made in Germany

The machine is equipped with:

• A shaft and disc tool cutting module on the Z-axis (automatically rotatable 0-90°)

• X-Y cross table module with linear motor technology and high-resolution measurement system

• Dual loading module constructed as a parallel shuttle, separated left/right with sliding doors

• Steel welded frame with two maintenance doors – left and right, ESD compatible

• Standard vision system basic module for teach-in programming

• Working area: 520 x 480mm

• Automatic milling cutter length processing

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement incl. protocol

• Air ionization

Bsdpevuw R Rjfx Aahjwi

• Milling cutter breakage control (for shaft cutters only)

• Preparation for vacuum clamping technology

• ESD powder coating, RAL 9002, disc and sliding doors

An optional dust extraction unit can be offered as a retrofit.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

The dynamic depaneling machine LOW 4322 XL is specifically designed for medium to high product volumes, meeting increasing requirements in the production process. PCB panels of various materials are separated using low-dust, low-stress sawing and milling techniques, ensuring maximum product flexibility, precision, and throughput. High-dynamic linear motor axes, tools, and grippers meet the highest quality standards, ensuring the depaneler offers long service life and reliability.

Semi-automatic Depaneling – Demand-driven Solutions

The LOW 4322 XL depaneler enables fast product changeover while maintaining short separating and handling times. Loading PCB panels is carried out via a parallel shuttle, and securing is done with pin clamping technology, optionally combined with vacuum suction when required.

Made in Germany

The machine is equipped with:

• A shaft and disc tool cutting module on the Z-axis (automatically rotatable 0-90°)

• X-Y cross table module with linear motor technology and high-resolution measurement system

• Dual loading module constructed as a parallel shuttle, separated left/right with sliding doors

• Steel welded frame with two maintenance doors – left and right, ESD compatible

• Standard vision system basic module for teach-in programming

• Working area: 520 x 480mm

• Automatic milling cutter length processing

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement incl. protocol

• Air ionization

Bsdpevuw R Rjfx Aahjwi

• Milling cutter breakage control (for shaft cutters only)

• Preparation for vacuum clamping technology

• ESD powder coating, RAL 9002, disc and sliding doors

An optional dust extraction unit can be offered as a retrofit.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2018

Pateikti užklausą

Telefonas & Faksas

+49 6173 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Matelica (MC)

Matelica (MC)

1 538 km

LAZERINIO PJAUSTYMO MAŠINOS - PJAUSTYMAS PLUOŠTO LAZERIU

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Mažas skelbimas

Butzbach

Butzbach

1 147 km

Apdirbimo centras

starrag HeckertHEC500D

starrag HeckertHEC500D

Mažas skelbimas

Vokietija

Vokietija

1 153 km

Dengimo sistema Venjakob Perfect, OIR, AirJet, UV

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

Mažas skelbimas

Burghaun

Burghaun

1 069 km

Jūrų konteineris

db-container20fuß

db-container20fuß

Mažas skelbimas

Bad Waltersdorf

Bad Waltersdorf

1 044 km

Stiklo pjovimo kėlimo stalas

Hegla

Hegla

Mažas skelbimas

Władysławowo

Władysławowo

314 km

Skaitmeninė spausdinimo mašina

DIP TECHGlassJet NOVO

DIP TECHGlassJet NOVO

Mažas skelbimas

Herzogenrath

Herzogenrath

1 279 km

Stiklo gręžimo staklės

SchramlTop Clear 13 Special- 4

SchramlTop Clear 13 Special- 4

Mažas skelbimas

Butzbach

Butzbach

1 147 km

Apdirbimo centras

starrag HeckertHEC400D

starrag HeckertHEC400D

Mažas skelbimas

Kornwestheim

Kornwestheim

1 224 km

Jūrų konteineris

db containerSeecontainer Materialcontainer Stuttgart

db containerSeecontainer Materialcontainer Stuttgart

Mažas skelbimas

Racibórz

Racibórz

682 km

GIĘTARKA DO RAMEK DYSTANSOWYCH

LISECBSV-45

LISECBSV-45

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida