Bėgimo Takelis pirkti naudotą (3 855)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Mažas skelbimas

Peskojai

Peskojai

187 km

Diržinis presas

ProFruit MachineryPOWERPRESS 3000

Skambinti

Gamybos metai: 2026, Sąlyga: naujas, Der gewonnene Saft fließt in einen integrierten Auffangbehälter unter der Presse. Anschließend befördert eine Pumpe den Saft aus der Presse in den gewünschten Tank zur weiteren Verarbeitung. Der Pressvorgang erfolgt kontinuierlich.

Leistung: 3.000 kg/h.

Das revolutionärste Merkmal unserer POWERPRESS-Bandpressenlinie ist, dass die Bandpressen über eine integrierte Pumpe und einen Saftauffangbehälter verfügen. Dadurch sparen Sie Kosten und benötigen keinen zusätzlichen Safttank und keine separate Pumpe, was Platz spart und zusätzliche Ausgaben vermeidet.

- Die Saftausbeute bei Äpfeln mit unserer Bandpresse 3000 beträgt ca. 75 %.

Bedpfoq Nl Aqex Agijcw

- Im Saftauffangbehälter ist ein Filtersieb integriert, das den Saft filtert und ein klares, reines Endprodukt gewährleistet.

- Die Bandpressen arbeiten vollautomatisch: Ist der Maischezulauftank voll, schalten sich alle vorgelagerten Maschinen automatisch aus. Wenn der Safttank gefüllt ist, fördert die Pumpe den Saft automatisch in die vorgesehenen Lagertanks.

- Die Bandpresse 3000 wird mit einer Hochdruckwaschanlage geliefert, die das Band der Maschine kontinuierlich reinigt. Unser Bandwaschsystem ist einfach konstruiert, enthält keine Motoren oder Getriebe und verlängert dadurch die Lebensdauer sowie reduziert die Wartungskosten.

- Das pneumatische Anheben der Sicherheitsabdeckung ermöglicht einen einfacheren Zugang bei Reinigungsarbeiten.

- Nach der Arbeit sollte die Bandpresse manuell mit einem Wasserstrahl gereinigt werden. Der komplette Reinigungsprozess dauert etwa 15–20 Minuten. Die Reinigung ist einfach, alle Teile der Bandpresse sind werkzeuglos leicht entnehmbar.

- Die Bandspannung ist einstellbar.

- Die Maschine besteht vollständig aus Edelstahl und verfügt über verstellbare Füße für eine komfortable Handhabung.

- Die Reinigung ist einfach, da es keine geschlossenen oder unzugänglichen Bereiche gibt und alle Teile leicht montierbar sind.

Mažas skelbimas

Bålsta (Stockholm)

Bålsta (Stockholm)

618 km

Scania G480 Euro 6, kanalų plovimo, vakuuminė ir perdirbimo įranga, 2013 m.

ScaniaG480 Euro 6, Sewer Jetter, Vacuum & Recycler, 2013

Skambinti

Sąlyga: geras (naudotas), rida: 153 950 km, galia: 353 kW (479,95 AG), pirmoji registracija: 06/2013, kuro tipas: dyzelinas, padangos dydis: 385/65R22,5, ašių konfigūracija: 8x4, ratų bazė: 3 900 mm, kuras: dyzelinas, kuro bako talpa: 300 l, stabdžiai: variklio stabdymas, spalva: balta, vairuotojo kabina: miegamoji kabina, pavaros tipas: pusiau automatinis, emisijos klasė: Euro 6, pakaba: oras, krovinio erdvės tūris: 16 m³, Gamybos metai: 2013, Įranga: AdBlue, EBS (Elektroninė stabdžių sistema), autonominis šildytuvas, elektrinis langų reguliavimas, kruizo kontrolė, navigacijos sistema, oro kondicionavimas, priešrūkiniai žibintai,

Mažas skelbimas

Bålsta (Stockholm)

Bålsta (Stockholm)

618 km

Siurbimo transporto priemonė

VolvoFL 10.320 12m3 Sludge / Vacuum & High Pressure-...

Skambinti

Sąlyga: geras (naudotas), rida: 472 700 km, galia: 234 kW (318,15 AG), pirmoji registracija: 01/1990, kuro tipas: dyzelinas, ašių konfigūracija: 4x2, ratų bazė: 4 400 mm, kuras: dyzelinas, spalva: geltonas, vairuotojo kabina: dieninė kabina, pavaros tipas: mechaninis, pakaba: plienas, krovinio erdvės tūris: 12 m³, Gamybos metai: 1990,

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

Siedlce

Siedlce

352 km

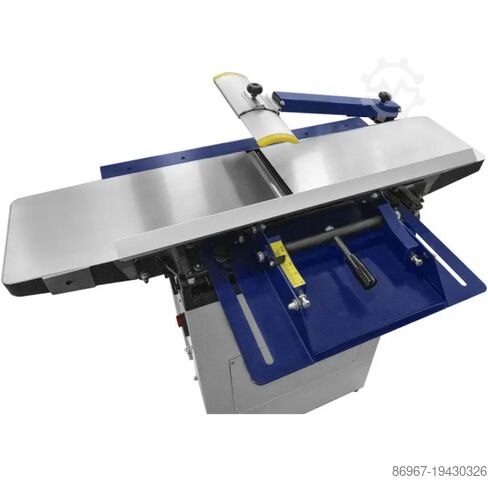

Obliavimo staklės

CORMAKPT250 400V

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Planer-thicknessers, jointers in the Cormak range

Our shop offers a wide selection of professional, versatile planers that combine stable operation with high surface accuracy at competitive prices. Acquire a tool that will accelerate your production and improve the quality of your wooden products, even for hobby use in home workshops. Cormak stands for satisfaction guaranteed.

Bcsdpfx Aovxh Nregijw

Construction and Operation of the Planer

Table: The thicknessing table is made from high-quality cast iron, ground and polished to a Ra 1.6 surface finish. Height adjustment is done via a large and ergonomic handwheel, which can be locked in place using an additional eccentric lever once the desired height is set.

Knives: The key element of the planer, installed above or below the table, are responsible for removing excess material from the wood surface. These knives are mounted on a rotating cutterblock or head.

Motor: The planer is powered by an electric motor that supplies the energy necessary to drive the cutterblock or planing head.

Cutterblock Guard: The guard can be freely adjusted for height, angle, and reach, allowing practical and user-friendly operation.

Feed Mechanism: The woodworking machine features drive and return rollers positioned very close to the cutterblock, enabling you to process even relatively short pieces. Feed roller drive is chain-based, ensuring slip-free operation and eliminating marking or gouging on the workpiece surface.

Guides: Guides ensure smooth and even movement of the workpiece. The angle guide can be smoothly set from 90° to 45°.

Stability: The heavy weight of the machine ensures high stability, providing safe, vibration-free operation, supported by anti-vibration feet.

Ease of Use: Adjustments are user-friendly, and switching from planing to thicknessing mode takes only a few seconds.

Technical Specifications for the Wood Thickness Planer:

Cutterblock diameter [mm]: 75

Cutterblock speed [rpm]: 4,000

Extraction port diameter [mm]: 100

Tilting fence angle [°]: 0 – 45

Number of knives: 3

Knife dimensions [mm]: 250 x 30 x 3

Maximum surfacing width [mm]: 254

Maximum thicknessing width [mm]: 254

Maximum planing height [mm]: 180

Maximum depth of cut (thicknesser) [mm]: 3

Maximum depth of cut (jointer) [mm]: 2.5

Thicknesser feed speed [m/min]: 6

Dimensions (L x W) [mm]: 1080 x 260

Gross weight [kg]: 152

Motor power: 2.6 kW

Power supply: 400V

Mažas skelbimas

Siedlce

Siedlce

352 km

Dviejų dalių mašinos veržlė F 160

CORMAKF160

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Properties and application

The body and movable jaw are made of high-quality cast iron

Bsdpfx Agsvxgq Ujiocw

Replaceable, serrated jaw inserts, induction hardened and ground

The use of a thrust bearing increases the efficiency of the clamping mechanism

Designed for clamping long workpieces using the full length of the machine table

Equipment included: handle, positioning keys

Mažas skelbimas

Siedlce

Siedlce

352 km

Ritininis tiektuvas

CORMAKHRT 1,86 m

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, Roller Conveyor 1.86 m – Efficient Roller Table for Precise Feeding of Heavy Workpieces

The 1,860 mm roller conveyor is a professional roller track designed for use with band saws, circular saws, and other metal cutting machines. Thanks to its robust construction and high load capacity, it is ideal for feeding and receiving workpieces such as pipes, shafts, or steel profiles. The presence of seven steel roller bearings ensures smooth and safe transport of materials of various shapes and weights.

Key Machine Features

7 steel rollers with a diameter of 60 mm and a length of 360 mm for even weight distribution

High load capacity – up to 900 kg – suitable for working with heavy and long materials

Height adjustment range from 650 to 1100 mm – perfect alignment with the machine tool

Stable steel construction with transverse reinforcements

Capability to connect several modules into a longer roller conveyor line

Construction and Technology

The roller conveyor is built from durable steel profiles, ensuring resistance to intensive use in industrial conditions. The seven rollers are mounted on ball bearings to provide precise and easy movement of workpieces. The modular design allows for easy extension of the feeding system, and the height adjustment allows optimal adaptation to various types of machines and workstations.

Precision and Work Efficiency

By using a roller conveyor with optimally spaced rollers, a stable position of the workpiece is ensured when feeding into or retrieving from the saw. Minimising rolling resistance, there are no vibrations and complete stability of parts, which directly translates into improved cutting quality, work safety, and time savings in batch processing.

Applications

CORMAK 1.86 m roller table is essential equipment for manufacturing plants, service companies, and workshops engaged in:

Cutting metal components – bars, pipes, sections

Bedpfx Aow E Hqgsgijcw

Machining heavy and long steel parts

Feeding materials to band and circular saws

Transporting elements between workstations

Standard Equipment

7 steel rollers with bearings

Reinforced steel frame with cross braces

Height adjustment system from 650 to 1100 mm

Feet with anti-slip protection

Technical data – 1.86 m roller conveyor

Roller diameter: 60 mm

Roller length: 360 mm

Number of rollers: 7

Conveyor length: 1,860 mm

Conveyor width: 450 mm

Height adjustment: 650–1100 mm

Maximum load capacity: 900 kg

Weight: 50 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Frezavimo ir gręžimo staklės

CORMAKZX7045B1 + DRO

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, The ZX7045 B1 DRO milling and drilling machine is an advanced tool designed for precise metalworking. It excels in drilling, reaming, and enlarging holes up to 45/40 mm in cast iron, as well as tapping threads up to M12 mm. With a milling capacity of up to 80 mm width and keyway milling up to 22 mm, this machine ensures versatile use. The ZX7045 B1 DRO variant is distinguished by an automatic spindle feed, increasing operational efficiency. Additionally, it is equipped with digital readout for enhanced accuracy, and a cooling system to maintain optimal temperature during machining. This machine is ready for immediate use and available directly from stock. It is ideal for professionals seeking high quality and performance in metalworking.

Product Features:

- HEAVY, STURDY CAST IRON CONSTRUCTION

- AUTOMATIC SPINDLE FEED

- MILLING HEAD HEIGHT IS ADJUSTED ON THE SUPPORT, NOT THE COLUMN

- ADDITIONAL LIQUID COOLING

- MASSIVE CROSS TABLE WITH PRECISELY GROUND SURFACE

- DOVETAIL GUIDEWAYS

- QUIET OPERATION THANKS TO GROUND GEARS

- LEFT AND RIGHT SPINDLE ROTATION

- ROTATING HEAD +/- 90°

- ADJUSTABLE HEAD HEIGHT

- DIGITAL READOUT

- Optional base available

TECHNICAL SPECIFICATIONS:

DRILLING CAPACITY IN STEEL: 32 mm

DRILLING CAPACITY IN CAST IRON: 45 mm

FACE MILLING CUTTER DIAMETER: 80 mm

END MILL CUTTER DIAMETER: 28 mm

SPINDLE SPEEDS: 50, 95, 100, 180, 190, 355, 360, 655, 710, 1260, 1310, 2520 rpm (6/12)

SPINDLE TAPER: MT4

SPINDLE TRAVEL: 125 mm (AUTOMATIC FEED)

WORK TABLE DIMENSIONS: 820 mm x 240 mm

BASE DIMENSIONS: 580 x 600 mm

MAX SPINDLE TO TABLE DISTANCE: 445 mm

SPINDLE TO COLUMN DISTANCE: 260 mm

TRAVEL X/Y/Z AXIS: 515/175/430 mm

QUILL FEED RATE: 0.12; 0.18; 0.25 mm/rev

HEAD SWIVEL LEFT/RIGHT: 90°

MOTOR POWER: 1.8 kW (2.5 HP)

POWER SUPPLY: 400 V

WEIGHT: 350 kg

Available Accessories:

- Drill chuck arbor MK4/B18

- Digital readout

- Hand tools

- Drill chuck 3-16 mm/B18

- Reducing sleeve MK4/MK3

Bcedsud H H Uspfx Agiew

- Reducing sleeve MK3/MK2

- Operating manual in English

Mažas skelbimas

Siedlce

Siedlce

352 km

Dirbtuvės aukšto slėgio plovimo įrenginys

CORMAKMP160

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, The workshop parts washer is a versatile tool that should be present in every service station, garage, or workshop. This indispensable device enables quick and cost-effective removal of contaminants. A major advantage is the ability to use the washer indoors.

Cleaning is performed in a closed circuit using a cleaning fluid heated up to 70°C. The solution is dispensed from the nozzle pistol under pressure up to 8 bar, allowing thorough cleaning of hard-to-reach areas and heavily soiled parts, such as those contaminated with soot, grease, or oil. Both the temperature and the cleaning agent boost washing effectiveness. Adjustable feet allow for leveling.

The washer is highly effective for turbocharger reconditioning and cleaning heavily soiled parts made of steel, cast iron, aluminum, and other alloys.

The washer lid is fitted with pneumatic actuators to increase safety and improve ease of use.

The washer features a dual-function spray gun that allows dispensing either compressed air only or air mixed with the cleaning agent. The cleaned part can be dried with compressed air.

The washer is equipped with an intuitive control panel.

- Adjustable water temperature

- Smooth air pressure adjustment

- Pressure gauge

- Separate switch for fluid/water heating

- Separate switch for power supply

Technical data:

- Capacity: 160 L

- Detergent heating: up to 70°C

- Bath fluid capacity: 8–14 L

- Working pressure: 5–8 bar

- Weight: 47 kg

- Dimensions: 770 x 600 x 1330 mm

- Air regulation

- Pneumatic spray gun

- Illuminated workspace

- Ventilation

Please note that the washer is delivered as a flat-pack for self-assembly.

The price does not apply to machines purchased in Poland.

Bedpjuc Tn Aefx Agiocw

Mažas skelbimas

Siedlce

Siedlce

352 km

Pjuvenų skutimosi ištraukimas

CORMAKDC2200P

Skambinti

Sąlyga: naujas, Funkcionalumas: visiškai funkcionalus, Gamybos metai: 2026, The extraction unit features high negative pressure and vibration-free operation. Thanks to its compact dimensions, it can be positioned under a panel saw table. All our extraction systems are easy to operate and allow for quick bag changes. The metal impeller ensures quiet and reliable, maintenance-free operation. The unit offers an excellent price-to-performance ratio. It is the perfect companion for saws, panel saws, planers, moulders, and similar woodworking machines.

Machine description

- For chips, sawdust, and dust from moulders, planers, saws, and more

- High suction power

- Easy to maneuver thanks to mobile chassis

- Metal impeller and housing

- Quick-release system for filter and bag

Its compact design requires minimal workshop space while maintaining a high extraction capacity of 2200 m³/h!

Technical specifications

Extraction capacity: 2200 m³/h

Bag diameter: 500 mm

Inlet diameter: 125 mm

Motor power: 2.2 kW / 400V

Dimensions: 1160 x 605 x 750 mm

Bjdpfxevuzt No Agijcw

Weight: 50 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Stiebo vežimėlis

CORMAKP513

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Product Description:

The P513 manual stacker truck is a device distinguished by high build quality and practical functionality. Its special steel construction ensures the stacker is robust, stable, and safe during operation. With a load capacity of 500 kg, it is the ideal tool for use in warehouses, retail environments, and for loading and unloading delivery vehicles.

The stacker features double polyurethane rollers, providing quiet, durable, and trouble-free operation. Moreover, with adjustable fork spread from 220 to 560 mm, it can accommodate various pallet sizes, significantly enhancing its versatility.

A specialist, reinforced foot pump with an easy-to-use, stepless lowering mechanism allows for precise control over the forks. Standard features also include a parking foot brake, ensuring secure and stable positioning during use.

The integrated overload valve plays a key role in protecting the device from damage caused by overloading, giving users peace of mind regarding both performance and safety.

The P513 manual stacker is the perfect solution for businesses valuing not just efficiency and functionality, but also workplace safety and equipment reliability.

Technical Specifications

Load capacity: 500 kg

Lifting height: 1300 mm

Fork dimensions (LxW): 850 x 110 mm

External fork width: 220-560 mm

Lowered fork height: 85 mm

Overall length: 1380 mm

Overall width: 570 mm

Turning radius: 1100 mm

Bjdpfjricqnex Agiocw

Steering wheels: 120 x 50 mm

Fork rollers: 70 x 30 mm

Unit weight: 105 kg

What sets us apart from the competition?

The P513 manual stacker stands out on the market due to numerous advantages. Its 500 kg load capacity makes it ideal for warehouse and retail environments. The specialist hydraulic pump allows for stepless lowering of the forks, ensuring both comfort and precision during operations.

We are confident in the quality of our pallet trucks, which is why we use a very robust design that ensures a long service life. Furthermore, we offer rapid service and replacement parts availability, making the use of our stackers even more safe and convenient. Nationwide shipping of parts and service is our standard.

Our pallet truck wheels and rollers are suitable for uneven surfaces, ensuring more stable and safer operation. The polyurethane rollers at the drawbar guarantee quiet and smooth performance. Additionally, all our stackers are equipped with an overload valve that protects the device in the event of excessive loading.

By choosing our pallet stackers, you are guaranteed quality, durability, and safety. We pay attention to every detail to ensure our clients receive the best stacker on the market.

Mažas skelbimas

Siedlce

Siedlce

352 km

Obliavimo staklės

CORMAKPT265 230V

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, The Cormak PT265 jointer-planer is a robust and well-engineered machine, offering extensive adjustment possibilities and the capability to process both hard and soft wood mechanically. Adjusting the planer is straightforward and switching between jointer and thicknesser modes takes just a few seconds.

Latest machine version with an innovative table opening system:

❌ Competing machines of the older design use 'butterfly' tables. Before each operation, the infeed and outfeed tables must be recalibrated relative to each other. Even slight misalignments can cause material damage and undesired results.

✔️ The new interconnected table system allows for precise, simultaneous adjustment of both tables. Once set, the tables remain permanently calibrated. When changing the planing height, both tables move in sync.

✔️ This solution not only saves time and increases working comfort but also improves planing accuracy by up to 30% compared to older systems. This enhancement is particularly crucial when working with thinner materials.

Stable, vibration-resistant construction

The machine’s substantial weight of 170 kg, combined with wide, ground cast iron tables (265 mm), ensures a high level of stability and safe operation.

Bedpfxjwu T S Ao Agiecw

Additional rubber feet enable operation without any noticeable vibration.

VERSION with the most powerful S6: 2.6 kW motor

The PT265 jointer-planer features an exceptionally powerful S6 2.6 kW (S1 2.2 kW) motor—significantly exceeding what competitive models offer, resulting in enhanced performance and stable operation.

A more powerful motor ensures stable operation and makes processing hardwoods effortless: Hard timber requires greater force for machining, which this robust motor handles with ease.

Effortless mode change from jointer to thicknesser

Switching from jointer to thicknesser mode is very quick and easy. It only requires unlocking the eccentrics, lifting the tables, and repositioning the chip extraction hood.

High working precision

- Smooth height adjustment of the tables with scale.

- The thicknessing table is centrally column-supported and equipped with a handwheel for up and down adjustments.

- Aluminum tilting fence (700x150 mm) with scale allows for precise angle setting from 90 to 45 degrees.

Technical specifications:

Knife shaft diameter [mm]: 75

Knife shaft speed [rpm]: 4000

Suction port diameter [mm]: 100

Tilting fence angle [°]: 90 - 45

Number of knives: 3

Shaft length [mm]: 262

Knife dimensions [mm]: 250x30x3

Max. planing width (jointer) [mm]: 265

Max. planing width (thicknesser) [mm]: 265

Max. planing height [mm]: 180

Max. planing depth (thicknesser) [mm]: 3

Max. planing depth (jointer) [mm]: 2.5

Thicknesser feed speed [m/min]: 6

Fence dimensions [mm]: 700 x 150

Machine dimensions (L x W) [mm]: 1080 x 269

Weight [kg]: 170

Total motor power: S6: 2.6 kW

Power supply: 230V

Mažas skelbimas

Siedlce

Siedlce

352 km

Pjuvenų dulkių siurblys

CORMAKFM230L1

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, NEW LOW-NOISE DUST EXTRACTOR / VACUUM MODEL FM230-L1

Robust extractor design and high vacuum pressure enable efficient extraction of chips and sawdust from machines as well as floor cleaning after work is completed.

Machine Description

- High-vacuum extractor (horizontal impeller arrangement)

- Balanced metal impeller

- Reinforced motor

- Suitable for cleaning entire workshop areas

- Large bag capacity

- Wide floor nozzle included

- Easy mobility thanks to large wheels

- Ergonomic handle for maneuvering

- High performance and QUIET OPERATION!

- Compact dimensions—space-saving in the workshop

Years of development by our team have led to the creation of the multi-blade metal impeller of the WhirlWind series, combined with a heavy-duty metal housing forming the heart of the extractor.

Bjdpfx Agjvu A Eaeiecw

The vacuum airflow efficiently collects excess sawdust generated during mechanical wood processing.

The heavy-duty extractor construction features a reinforced frame for stable, vibration-free operation. The entire structure is further strengthened with properly sized braces supporting both the discharge cylinders and the weight of the waste bags, keeping them secure on a solid base.

An additional advantage is the use of a flexible and durable seal placed at a critical point to enhance system tightness.

Standard equipment includes a canvas filter bag and a disposable plastic collection bag. Flexible metal bands ensure long-term, trouble-free bag replacements.

Swivel, ball-bearing castor wheels provide easy movement of the extractor throughout the facility.

Technical Specifications:

- CONTINUOUS DUTY MOTOR POWER S1: 0.75 kW

- SPEED: 2800 rpm

- EXTRACTION CAPACITY: 1000 m³/h

- BAG VOLUME: 60 l

- NUMBER OF BAGS: 2

- SUCTION INLET DIAMETER: 100 mm

- HEIGHT: 1550 mm

- WIDTH: 420 mm

- LENGTH: 800 mm

- VOLTAGE: 230 V

- WEIGHT: 27 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Automatinis kolonų pjaustytuvas

CORMAKH-260SA przecinarka taśmowa do metalu

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, The CORMAK H - 260 SA Automatic Column Band Saw is a high-performance machine designed for automatic cutting cycles of bars, pipes, and profiles made from steel, cast iron, and non-ferrous metals. A robust body and heavy-duty saw frame combined with a column design ensure excellent rigidity and an exceptional level of stability during the cutting of even the most challenging materials. The saw is equipped with a PLC controller and a user-friendly touchscreen interface.

Bodpoiz S I Hsfx Agiscw

This saw allows for operation in both manual and automatic modes.

Manual Mode enables all operations to be performed manually from the machine’s control panel.

Automatic Mode – once the machine is started, the entire cutting cycle, i.e., clamping the workpiece in the vise, feeding it to the set length towards the saw blade, lowering and raising the saw arm to the required height after the cut, takes place automatically, without the need for operator intervention.

Cutting parameters such as the number of cut pieces, their dimensions, saw blade speed, and arm descent rate are set on the control panel. The machine will automatically stop at the end of the programmed series, in the event of a blade breakage, or in case of other faults detected by the machine’s control system.

The machine body is a cast iron component mounted on a rigid, heavy-duty frame. The enclosure houses the hydraulic unit, coolant tank with pump, and swarf conveyor.

The blade drive uses an inverter-controlled motor, allowing for smooth and wide-range speed adjustment. The hydraulic blade tensioner provides optimal working conditions. In the event of blade breakage, the machine stops automatically. Maximum cutting performance and extended blade life are ensured by the cooling system and a cleaning brush.

A hydraulic material feeder delivers a fully automatic working cycle. The controller, equipped with an LCD display, enables programming of all saw functions, indicates material end, reports faults, and provides data on the number of cuts after the programmed cycle. Maximum feed length per single stroke is 500 mm with an accuracy of +/- 0.2 mm per stroke.

The innovative design and manufacture of CORMAK semi-automatic and automatic band saws according to ISO:90001 and ISO:140001 standards guarantee safety, quality, and reliability. Reliable operation is further assured by the use of motors licensed by ABB, a world-renowned industry leader.

Technical Data

Cutting range: Ø260 or 260 x 260 mm

Blade: 3150 x 27 x 0.9 mm

Cutting speeds: 40/60/80 m/min

Motor: 2.2 kW

Hydraulic power unit: 0.75 kW

Coolant pump: 0.09 kW

Feeder stroke: 500 mm

Load capacity: 1500 kg

Dimensions: 1600 x 1800 x 1550 mm

Weight: 1000 kg

Maximum cutting range

Angle

0º ø260 | 260 × 260 mm

Standard Equipment

- Automatic cycle operation

- Arm position memory function

- Built-in hydraulic unit

- Vise position memory function

- Variable cutting speeds

- Driven blade cleaning brush

- Cooling system

- Bimetal band saw blade

- CE Declaration of Conformity

- User manual (DTR) in Polish and English

For more information, please visit our website.

Mažas skelbimas

Siedlce

Siedlce

352 km

Kabinės aukšto slėgio plovimo įrenginys

CORMAKINOX MP180

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, The pressure cabin washer made from high-quality stainless steel is a tool that elevates cleaning standards to a new level. Specifically designed for professional applications, this washer offers reliability, durability, and high performance.

Manufactured from premium-grade stainless steel, it ensures longevity and resistance to environmental conditions, guaranteeing sustained efficiency even in the most demanding working environments.

Device Description:

Thanks to its robust stainless steel construction, our cabin washer is corrosion-resistant and provides long-lasting performance even in tough conditions. Equipped with advanced pressure technology, it effectively removes dirt, oil, grease, and other contaminants from various surfaces.

Bedpfx Asuc Tpyjgijcw

Our pressure cabin washer is an essential tool for businesses that value cleanliness, efficiency, and reliability. It makes cleaning tasks easier, faster, and more effective, translating to greater customer satisfaction and improved operational productivity.

Washing is performed in a closed circuit using a cleaning fluid heated up to 70°C. The cleaning agent is sprayed from the pistol nozzle at pressures up to 8 bar, ensuring thorough cleaning of hard-to-reach areas and heavily soiled parts contaminated with carbon deposits, grease, or oil. Both the temperature and cleaning fluid enhance washing efficiency. The washer features adjustable feet and easy level regulation.

The washer is equipped with a dual-function gun, which can dispense either only air or air mixed with the cleaning agent. This allows the washed item to be dried with compressed air.

Advantages of using the stainless steel pressure cabin washer include:

1. Thanks to high water pressure combined with detergents, the washer removes even the most stubborn contaminants, such as oil, grease, or rust, leaving surfaces clean and shiny.

2. The cabin washer enables quick and efficient cleaning of larger areas in less time compared to traditional manual cleaning methods.

3. With various pressure setting options, the washer can be adapted to different types of surfaces and contamination, making it a highly versatile cleaning tool.

4. Made from high-quality stainless steel, the washer is resistant to corrosion and mechanical damage, ensuring a long service life and minimal maintenance needs.

5. The cabin washer is user-friendly, enabling operators to quickly learn how to use it and achieve professional results without lengthy training.

6. Fast and effective cleaning increases productivity, potentially leading to significant time and cost savings for businesses.

Using a stainless steel pressure cabin washer is not only an investment in cleanliness, but also in efficiency and durability, providing benefits for both companies and individual users.

Technical specifications of the MP180 washer:

- Washing capacity: 180 l

- Frequency: 50 Hz

- Weight: 56 kg

- Voltage: 230 V

- Height with legs: 1450 mm

- Height without legs: 920 mm

- Internal width: 740 mm

- Internal height (lid open): 410 mm

- Internal depth: 500 mm

- Loading height: 360 mm

- Loading width: 700 mm

Mažas skelbimas

Siedlce

Siedlce

352 km

Dirbtuvės aukšto slėgio plovimo įrenginys

CORMAKMP150

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Funkcionalumas: visiškai funkcionalus, WORKSHOP PRESSURE WASHER MP150

Features:

The cleaning process operates in a closed loop using a washing fluid. The agent is sprayed from the gun nozzle at a pressure of up to 8 bar, ensuring thorough cleaning of hard-to-reach areas and parts heavily contaminated with carbon deposits, greases, or oils.

This washer is ideal for the refurbishment of turbochargers and for cleaning heavily soiled components made of steel, cast iron, aluminium, and other alloys.

The washer lid is fitted with pneumatic actuators, enhancing both safety and ease of operation.

The cabinet is factory-equipped with work area lighting.

The washer is fitted with a dual-function gun, which can dispense either air only or air with the cleaning agent. Washed parts can be dried with compressed air.

* Please note, the washer is supplied as a self-assembly kit.

Technical Data

Capacity: 160 L

Fluid tank capacity: 8–14 L

Working pressure: 5–8 bar

Weight: 29 kg

Air regulation

Bodovugwmjpfx Agiscw

Pneumatic gun

Illuminated chamber

Work area ventilation

Dimensions: 770 x 610 x 700 mm

Mažas skelbimas

Siedlce

Siedlce

352 km

Ritininis tiektuvas

CORMAKHRT 1,8 m 6 rolek

Skambinti

Sąlyga: naujas, Funkcionalumas: visiškai funkcionalus, Gamybos metai: 2026, The 1.8 m roller conveyor is a professional roller conveyor designed to work with band saws, circular saws, and other metal cutting machines. Thanks to its robust construction and high load capacity, it is perfect for feeding and receiving workpieces such as pipes, shafts, or steel profiles. The presence of six steel rollers ensures smooth and safe transport of materials of various shapes and weights.

Key Features

- 6 steel rollers with a diameter of 40 mm and a length of 400 mm for even weight distribution

- High load capacity – up to 900 kg – enables operation with heavy and long materials

- Height adjustment in the range of 750–1150 mm – perfect alignment with the machine tool

- Stable steel construction with cross reinforcements

- Option to connect multiple modules to create a longer roller conveyor system

Design and Technology

The roller conveyor is constructed from durable steel profiles, ensuring resistance to heavy industrial use. The six running rollers are mounted on ball bearings, providing precise and effortless movement of machined parts. The modular design allows for easy extension of the feeder system, while height adjustment enables optimal fit for various types of machines and workstations.

Precision and Work Efficiency

By using a roller conveyor with properly positioned rollers, stable positioning of the workpiece is achieved when feeding to or receiving from a saw. Reduced rolling resistance, absence of vibrations, and full workpiece stability directly result in improved cutting quality, increased workplace safety, and time savings in batch processing.

Applications

The CORMAK 1.8 m 6-roller conveyor is an essential piece of equipment for manufacturing plants, service companies, and workshops involved in:

- Cutting metal workpieces – bars, pipes, sections

- Machining heavy and long steel components

- Feeding material to band and circular saws

- Transporting workpieces between workstations

Standard Equipment

Bedpfjxhd Dajx Agijcw

- 6 steel rollers with bearings

- Reinforced steel frame with crossbars

- Height adjustment system 750–1150 mm

Technical specifications – 1.8 m 6-roller conveyor

Roller diameter: 40 mm

Roller length: 400 mm

Number of rollers: 6

Conveyor length: 1800 mm

Conveyor width: 470 mm

Height adjustment: 750–1150 mm

Maximum load capacity: 900 kg

Weight: 40 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Pramoninės išmetimo sistemos

CORMAKDCV6500TC

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Thanks to many years of experience of our CORMAK team, the DCV series extractors in the TC Viber version have been developed.

The design of a new technological line has enabled us to create top-class extractors.

Advantages:

- Equipped with an additional pair of doors for easier bag replacement

- The DCV 6500TC extractor marks another milestone in the production of efficient dust and chip extractors, designed to maintain consistent extraction parameters throughout the entire work cycle

- The new TC series offers a fully enclosed upper housing that absorbs noise and vibrations during operation, as well as the ability to return warm air

- Maintenance-free filter shaking system with the option for automatic operation

- Newly patented safety system ensures reliable operation of the device

- Durable, robust construction ensures quiet and vibration-free operation of the extractor

- Compact footprint, yet capable of filtering large amounts of dust and chips

- Powerful and quiet fan provides high negative pressure performance

- Reliability confirmed by manufacturing facilities coping with high daily workloads

- Specially designed impeller blades make the units more efficient and effective, also contributing to energy savings

- Very high tightness of the entire suction system guarantees the highest indoor air quality and, during the heating season, prevents heat loss

- Large filter area

- Possibility to build an overhead system connecting several machines operating simultaneously with DCV 6500 extractors

- Fast replacement of waste bins, designed to maintain 99.99% system airtightness

- Metal waste bins with mobile running gear for easy and trouble-free movement. Also equipped with a sight glass to check the fill level of the containers

- Low-noise operation and high efficiency ensured by a balanced metal impeller and upgraded motor

- Provides perfection and cleanliness at the workstation, directly impacting the quality of your products

- Excellent cooperation with machines such as sanders, edgebanders, panel saws, etc.

- Control cabinet for switching the device on/off

- We guarantee high purification quality!

- Polyester filter traps dust down to 5 microns; for filtering smaller particles, use e.g. a HEPA filter

- Do not use this extractor in explosive atmospheres

- The extractor is intended for use in the woodworking industry with sawdust, chips, and dust (not suitable for wet material such as wet sawdust)

- Before starting the extractor, remove the lower beam to allow access to the chip containers

- MADE IN POLAND

Technical specifications:

MOTOR POWER (CONTINUOUS S1):

5.5 kW / 400 V, 50 Hz

SPEED:

2900 rpm

EXTRACTION CAPACITY:

6500 m³/h

SUCTION PORT DIAMETER:

Bcsdpsuc U N Uefx Agisw

280 mm

SUCTION SPEED:

28–32 m/s

FILTER AREA:

16 m²

FILTER MATERIAL:

Polyester, 5 microns

NUMBER OF FILTERS:

32

WASTE BIN CAPACITY:

500 L

DIMENSIONS:

2440 x 930 x 2270 mm

WEIGHT:

440 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Dviejų dalių mašinos veržlė

CORMAKF200

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Properties and Applications

- The body and movable jaw are made of high-quality cast iron

- Replaceable, serrated jaw inserts, induction-hardened and ground

- The use of a thrust bearing increases the efficiency of the clamping mechanism

- Designed for clamping long workpieces using the full length of the machine table

- Equipment: handle, positioning keys

- Bolt spacing range: 135 - 180 mm, slot width: 18 mm.

Bcsdpfxevxgp Ds Agiow

Mažas skelbimas

Siedlce

Siedlce

352 km

Stiebo vežimėlis

CORMAKWRHS 1016

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Specification of the WRHS 1016 Pallet Stacker:

Our versatile WRHS1016 mast stacker is a reliable tool for efficient handling and storage of goods in various environments such as warehouses, retail spaces, and for loading and unloading pallets in delivery vehicles. With a lifting capacity of up to 1,000 kg, it is the ideal solution for transporting a wide range of goods.

This model is equipped with polyurethane rollers, ensuring stability, quiet operation, and long-lasting, trouble-free usage. The rollers allow the stacker to move smoothly over the ground, minimize noise, and ensure efficient material handling.

The robust frame provides long-term durability. The solid construction of the WRHS1016 makes it resistant to heavy loads and tough working conditions. This guarantees the user that the pallet stacker will reliably support logistics operations for years.

Our universal WRHS1016 mast stacker with a 1,000 kg capacity, 1,600 mm lifting height, polyurethane rollers suitable for uneven surfaces, adjustable fork width, specialist hydraulic pump for stepless fork lowering, extremely robust frame, convenient maintenance with readily available spare parts, overload valve, 190° handle steering, rounded fork tips, and a handle coated with a rubber layer offers unmatched functionality, performance, and safety. It is a comprehensive tool that meets the requirements of even the most advanced logistics operations and the most demanding users. Only our WRHS1016 mast stacker enables efficient load handling in all conditions, ensuring both productivity and operator comfort.

Technical specifications:

- Lifting capacity: 1,000 kg

- Lifting height: 1,600 mm

- Fork dimensions (L x W): 1,150 x 145 mm

- External fork width: 290 - 845 mm

- Height with lowered forks: 2,080 mm

- Height with raised forks: 2,080 mm

- Minimum fork height: 90 mm

- Overall length: 1,630 mm

- Overall width: 900 mm

- Turning radius: 1,200 mm

- Steering wheels: 180 x 50 mm

- Fork rollers: 74 x 70 mm

- Weight: 208 kg

Our competitive advantages:

- Lifting capacity up to 1,000 kg

- Specialist hydraulic pump allows stepless lowering of forks

- Extremely robust construction for extended service life

- Adjustable fork width for handling non-standard loads

- Immediate service support and spare parts available nationwide

- Wheels and rollers suitable for uneven surfaces: polyurethane at the tiller

- Overload valve for added stacker protection

- Handle steering up to 190°, rounded fork ends for easy entry under pallets, handle coated with rubber for improved ergonomics

- Load lifting via hand lever or foot pedal

- EXCLUSIVE! For enhanced safety, foot-operated parking brakes on both wheels!

- Only our stacker enables you to fully lower the maximally extended forks to handle wide loads!

Bsdsricb Sspfx Agiecw

Mažas skelbimas

Siedlce

Siedlce

352 km

Automatinis kolonų pjaustytuvas

CORMAKH-300SA przecinarka taśmowa do metalu

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, The automatic column-type band saw CORMAK H - 300SA is a high-performance machine designed for automatic cycle cutting of bars, pipes, and profiles made of steel, cast iron, and non-ferrous metals. Its robust saw frame and column construction ensure excellent rigidity and outstanding stability during the cutting process, even with the most challenging materials. The saw is equipped with a PLC controller and an intuitive touchscreen interface.

Bcsdjiz S Nyepfx Agiow

Manual mode allows all operations to be performed from the machine’s control panel.

Automatic mode – upon activation, the complete cutting cycle, including clamping the workpiece in the vise, advancing it to the selected length, lowering the saw arm for cutting, and raising the arm to the preset height after the cut, proceeds without operator intervention.

Cutting parameters such as number of cut pieces, their dimensions, blade speed, and descent speed are set via the control panel. The machine stops automatically upon completion of the programmed batch, in case of blade breakage, or if another fault is detected by the saw’s control system.

The blade drive, based on a frequency-inverter-controlled motor, provides smooth speed adjustment over a wide range. In the event of blade breakage, the machine halts automatically. Accurate blade guidance is ensured by guide bearings and carbide inserts. The movable blade guide head is set according to the size of the material, which enhances blade stability. A coolant system and cleaning brush prolong blade life and maintain optimal cutting conditions.

Hydraulically forced descent of the arm is precisely adjustable via a throttle valve. The rapid-feed system shortens cutting times for individual sections.

The hydraulic feed system enables a fully automatic operation cycle. The controller, equipped with an LCD display, facilitates programming of the saw, signals material end, displays errors, and provides a cut-piece counter after the programmed cycle. Maximum material feed per stroke is 500 mm, with accuracy of +/- 0.2 mm per stroke.

Technical Data:

Cutting capacity: ∅ 300 mm / □ height 300 mm x width 300 mm

Bundle cutting: max 260 x 90 mm

Blade (length x width x thickness): 3505x27x0.9 mm

Cutting speeds: 40/60/80 m/min

Feed speed: hydraulic, stepless adjustment

Motor: 3.8 kW

Hydraulic unit: 0.75 kW

Coolant pump: 0.09 kW

Feeder stroke: 500 mm

Load capacity: 1500 kg

Dimensions (L x W x H): 1750 x 1950 x 1550 mm

Weight: 1200 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

Lazerinis suvirinimo aparatas

CORMAKWL3000

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, Introducing the latest model of the CORMAK WL3000 industrial laser welder, which combines advanced FIBER technology with innovative design solutions, offering unmatched precision and performance. This device is designed for welding various types of metals, delivering top-level quality and repeatability of welds. With its 3-in-1 function enabling welding, cutting, and laser cleaning, the unit is versatile and efficient across many industrial sectors.

Key Features and Advantages

Advanced cooling system: The new, more efficient water-cooling system ensures optimal operating temperature, allowing for longer uninterrupted work and extending the device's lifespan.

Innovative design: The ergonomic and lightweight welding head design allows for welding even in hard-to-reach areas. With the adjustable spot size (0-5 mm) and interchangeable nozzles, the operator has full control over the welding process.

User-friendly – thanks to the applied solutions and thoughtful construction, the operator can start working after a short training session.

Low indirect radiation – during operation, protective goggles for filtering strong light are sufficient.

Significantly faster welding than traditional methods; efficiency can increase by 3 to 10 times.

Bedpfxskkbw Ue Agiecw

Focused beam: minimal structural change due to the small heat-affected zone.

Repeatable welds – the weld seam is clean, and the joints offer high strength.

Capable of welding very thin materials, such as 0.5 mm stainless steel.

Option to weld with or without filler wire.

Integrated laser cleaning function enhances the device’s range of applications.

Cutting option – delivers excellent cutting quality, requiring no mechanical processing.

Technical Specifications

Maximum power: 3000 W

Laser wavelength: 1070 nm

Fiber length: 10 m

Operating modes: Continuous / Modulated

Air pressure: 10 – 15 L/min

Welding speed: 0–215 mm/s

Automatic wire feeder: Ø 0.8 – 2.0 mm

Maximum power consumption: ≤11.0 kW

Focal length: 150 mm

Cooling system: Water-cooled

Operating voltage: 400V

Shielding gas consumption: 20 L/min

Dimensions: 600 x 1100 x 1100 mm

Weight approx.: 207 kg

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Siedlce

Siedlce

352 km

Universalus metalo tekinimo staklės

CORMAKTytan 750 PRO(400V)

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, TYTAN 750 PRO (VARIO) 400V metal lathe (without base) with stepless spindle speed adjustment. This lathe is designed for machining external and internal cylindrical surfaces, thread cutting, drilling, counterboring, and reaming. It is commonly used in small manufacturing operations, workshops, garages, etc. This is the machine version without a base.

The TYTAN 750 PRO universal lathe, with its continuous spindle speed adjustment, is ergonomic and tailored to the needs of the user. The reduced setup time when machining a wide range of part sizes translates into productivity and ease of use.

VARIO version – electronic, stepless spindle speed adjustment via a DC motor and voltage controller. This ensures the highest rotational accuracy of the lathe chuck, resulting in improved quality of the machined components.

Main advantages:

- Modern DC motor with smooth spindle speed adjustment provides user convenience and shortens calibration time.

- LCD screen with spindle speed display allows monitoring and rapid adjustment of spindle speed when setting cutting and threading modes.

- Two spindle speed ranges: low (50-1125 rpm) for machining hard steels and high (100-2250 rpm) for high-speed precision turning.

- Thread cutting: metric – 18 pitches (0.2–3.5), imperial – 21 pitches (8–56 T.P.I.), capable of cutting both left-hand and right-hand threads.

- Automatic longitudinal feed with 6 feed rates (0.07 to 0.40 mm/rev) considerably shortens machining time without compromising quality when turning long parts.

- The machine is fully compliant with EU directives (CE) as well as Polish standards and DIN norms.

Technical specifications:

- 3-jaw chuck: 125 mm

- Max. turning diameter over bed: 250 mm

Bcjdjvvlxlspfx Agiew

- Turning diameter over carriage: 150 mm

- Turning length between centers: 750 mm

- Max. length of installed workpiece (chuck/center): 700 mm

- Bed width: 135 mm

- Spindle bore: 27 mm

- Spindle taper: MT4

- Tool post dimensions: 65 x 65 x 20 mm

- Maximum tool size: 12 x 12 mm

- Top slide travel: 70 mm

- Cross slide travel: 135 mm

- Longitudinal travel: 650 mm

- Spindle speed adjustment: stepless (L/H)

- Spindle speed: L: 50-1125 / H: 100-2250 rpm

- Number and range of metric threads: (18) 0.2–3.5 mm/rev

- Number and range of imperial threads: (21) 8–56 T.P.I.

- Number and range of longitudinal feeds: (6) 0.07–0.4 mm/rev

- Tailstock quill diameter: 30 mm

- Tailstock quill travel: 60 mm

- Tailstock quill taper: MT2

- Motor power S1/S6: 1.1/1.32 kW

- Dimensions (L/W/H, without base): 1310 x 610 x 480 mm

- Weight (without base): 165 kg

Mažas skelbimas

Siedlce

Siedlce

352 km

MEDIENAI IR METALUI ŠLIFIMO STALAS

CORMAKDT2000M

Skambinti

Gamybos metai: 2026, Sąlyga: naujas, Professional table designed for sanding wood and metal.

Filtration unit suitable for all grinding and sanding applications.

THE TABLE IS EQUIPPED WITH TWO FANS ON THE RIGHT AND LEFT SIDE

The table features an independent dual filtration system, ensuring thorough air purification from all contaminants! The special high-efficiency radial fan guarantees long operational times without the need to replace filtration media. The eleven-segment worktop facilitates workpiece positioning and filter cleaning. Filters can be replaced quickly and easily. The ventilation system is integrated into the bottom and side wall of the table. Segregation of "large" and "small" abrasive waste is provided. The filter is resistant to high temperatures, but is not fireproof. Spacious metal drawers are located on both the right and left sides of the table. High negative pressure (dust filtration efficiency > 99.9%).

Technical specifications:

Worktop dimensions: 2060 x 530 mm

Bcodpfevugxwsx Agiow

Motor power: 2 x 1 kW

Airflow capacity: 2 x 4000 m³/h

Filter size: 493 x 395 x 20 mm

Voltage: 230V

Overall dimensions: 2160 x 600 x 870 mm

Weight: 120 kg

The listed price is net. Transport costs are not included in the price.

Mažas skelbimas

Siedlce

Siedlce

352 km

Suklio reguliavimo padėties reguliatorius

CORMAKPozycjoner nastawczy wrzeciona GT12

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, The neodymium spindle positioning adapter for tapping arms is a modern tool that allows for precise alignment of the tapping unit at a perfect right angle to the workpiece. With this adapter and the use of a 90° setting gauge, users can easily and effectively achieve exact positioning.

Product features:

The neodymium spindle positioning adapter for tapping arms is an innovative tool that enables the precise setting of the tapping unit at a perpendicular angle relative to the workpiece. By utilizing a 90° setting gauge, this adapter ensures reliable and accurate positioning.

The positioning procedure with this adapter is simple and effective. The following steps should be taken:

1. Install the adapter on the spindle: With the power supply switched off, mount the adapter onto the spindle of the tapping head. Ensure that the adapter is properly seated and securely fixed in place.

2. Loosen the joints: Make sure all the joints on the adapter are loosened. If the head has the ability to rotate 360 degrees, also loosen the joints on that part. This will allow the adapter to move freely for precise angle adjustment.

3. Attach the magnet to the workpiece: Secure the magnet onto the workpiece. The magnet should be firmly and stably positioned to guarantee secure and precise positioning.

With this adapter, the user can effortlessly position the tapping unit at a right angle to the workpiece. This innovative technology delivers effective and accurate results, enabling precise thread cutting.

The positioning adapter is compatible with electric tapping units available on our website: RGM16PW and RGM16W.

Bodpov Axu Tofx Agiecw

Manufacturer: Cormak

Mažas skelbimas

Siedlce

Siedlce

352 km

Pramoninės išmetimo sistemos

CORMAKDCV4500 Viber

Skambinti

Sąlyga: naujas, Gamybos metai: 2026, CORMAK DCV Series Dust Extractors have been developed primarily for filtering very fine dust particles. They are designed to self-clean in an automatic cycle, entirely without operator intervention. Our engineering department has placed great emphasis on developing a motorized filter shaking system, in which the entire filter cleaning cycle is performed automatically in a closed system.

Advantages of DCV Dust Extractors

- Durable, robust construction ensuring quiet and vibration-free operation of the dust extractor

- Very high airtightness of the entire suction system, guaranteeing optimal air quality inside the workshop and heat retention during the heating season

Bodpfx Ajuc Unqjgiecw

- Powerful and quiet centrifugal fan providing high vacuum performance

- Possibility to build an overhead duct system and deliver extraction to several machines operating simultaneously with DCV units

- Reliable automatic filter cleaning system

- Mobile chassis system for easy relocation throughout the facility

- Waste containers designed to maintain 99.99% system tightness, equipped with a mobile carriage system

- Control cabinet enabling precise monitoring of filter contamination and device on/off control

- Polyester filter retains particles as small as 5 microns; for finer filtration, e.g. HEPA filters are required

- Use of this dust extractor in explosive atmospheres is strictly forbidden

- The extractor is designed for woodworking applications with sawdust, chips, dust (not suitable for wet raw materials such as wet sawdust)

- Prior to operation, the lower beam must be removed to provide free access to the chip containers

Technical Specifications

MOTOR POWER (CONTINUOUS S1): 3.0 kW

SPEED: 3000 rpm

EXTRACTION CAPACITY: 4500 m³/h

SUCTION INLET DIAMETER: 200 mm

SUCTION SPEED: 28-32 m/s

FILTER AREA: 6 m²

FILTER MATERIAL: Polyester, 5 microns

NUMBER OF FILTERS: 18

DIMENSIONS: 752 x 1502 x 2200 mm

WEIGHT: 200 kg

Palengviname jums paiešką: "bėgimo takelis"

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota Bėgimo Takelis (3 855)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- Batsiuvystė Staklės Frezavimo Ir Šlifavimo Staklės

- Bcs 745

- Bi-Ašinis Maišytuvai

- Darbuotojų Saugos Ir Sveikatos

- Dėkingi Už Fer Lentynos

- Dėžės Ir Talpos

- Fngj 20

- Ga 11 Ff

- German

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo