Etiketatorius + skaitytuvasLOGOPAK

LOGOMATIC 415 T + Scanner

Etiketatorius + skaitytuvas

LOGOPAK

LOGOMATIC 415 T + Scanner

Gamybos metai

2020

Sąlyga

Naudotas

Vieta

Norderstedt

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Etiketatorius + skaitytuvas

- Gamintojas:

- LOGOPAK

- Modelis:

- LOGOMATIC 415 T + Scanner

- Gamybos metai:

- 2020

- Sąlyga:

- geras (naudotas)

- Funkcionalumas:

- visiškai funkcionalus

- Darbo valandos:

- 200 h

Kaina ir vieta

- Vieta:

- Norderstedt, Vokietija

Skambinti

Techniniai duomenys

- Bendras plotis:

- 700 mm

- Bendras ilgis:

- 800 mm

- Bendras aukštis:

- 2 297 mm

- Įvesties srovės tipas:

- Oro kondicionierius

Pasiūlymo informacija

- Sąrašo ID:

- A20023865

- Naujinta paskutinį kartą:

- Data 2025.09.18

Aprašymas

You can find this and other machines that were part of our dispatch line in our listings. If you are looking for a complete solution in this area, or if you require several components, feel free to contact us and we will get back to you promptly.

Brief overview of the dispatch line and where the offered item was used:

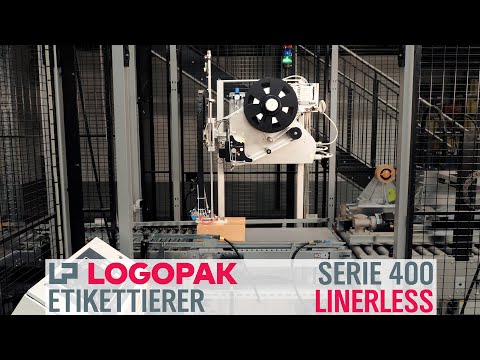

The dispatch line was used for pallet shipping, meaning cartons were erected (SOCO ATS 2300 + 2200) and sealed at the bottom to be packed on the main dispatch line. The completed parcels were then top-sealed by a carton sealer (SOCO T-4200) and forwarded to a label applicator (LOGOPAK LOGOMATIC 415-T). Once the Logomatic scanner verified error-free parcels, these were transferred to the palletizing robot (SOKO PRS-LRS-1218-H3), which stacked the pallet according to our specifications/sizes. Our video shows the entire dispatch line in operation.

The item offered here is the LOGOMATIK 415-T label applicator from LOGOPAK (highlighted with a blue circle in the layout image).

Summary of all relevant technical data for the LOGOMATIC 415 T labelling system:

• Machine type: LOGOMATIC 415 T.

• Print resolution: 300 dpi (12 dot).

Hedpexdcv Hsfx Af Isng

• Cycle capacity: Maximum 20 products per minute.

• Operation: HMI (10" colour LC display) in German.

• Signal light: 3-colour status light (red, blue, green) present.

• Frame: Standard frame with stainless steel spindle leveling feet (±50 mm adjustment).

• Certification: CE certified (EU).

• Mains voltage: 230V AC / 50 Hz (L,N,PE). Supply voltage should fluctuate by no more than ±5% and must be free from interference.

• Power consumption: Maximum approx. 1400 VA.

• Electrical connections at installation site: 1x Schuko socket for the labeler and 1x Schuko socket for maintenance purposes.

• Compressed air: 6 bar, dry and oil-free. The air supply must be permanently installed up to approx. 1 meter before the device.

• Compressed air consumption: Approx. 250 l/min.

• Compressed air connection: ½ inch permanent line with FESTO quick coupling KD4-½-A and coupling plug KS4-CK-6.

• Temperature: The ambient temperature for the labeler should be between +5°C and +37°C. For processing PE labels, 25°C is recommended.

• Applicator stroke length (net): 350 mm, defines the working area for different carton heights.

• Labelling height: 800 mm (standard setting).

• Orientation: Horizontally standing for top labelling.

• Label unwind/carrier take-up: For rolls up to 600 m running length.

• Label core adapter: 152 mm (6 inches).

• Current format (Amazon): 60 mm width x 40 mm height.

• Future shipping label: Approx. 100 mm width x 200 mm height. These dimensions can be varied depending on required label size.

• Label gap: 8 mm.

• Printing method: Thermal transfer.

• Label material: Paper labels (Paper Economy TT).

• Ribbon (TTR): Wax quality.

• Interface: Ethernet (10/100 Mbit). A serial RS-232C interface is also available.

• Data protocol: ZPL (Zebra).

• Data source: Host system.

• Data transmission: The data to be printed is sent from a PC to the labeler via Ethernet.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Brief overview of the dispatch line and where the offered item was used:

The dispatch line was used for pallet shipping, meaning cartons were erected (SOCO ATS 2300 + 2200) and sealed at the bottom to be packed on the main dispatch line. The completed parcels were then top-sealed by a carton sealer (SOCO T-4200) and forwarded to a label applicator (LOGOPAK LOGOMATIC 415-T). Once the Logomatic scanner verified error-free parcels, these were transferred to the palletizing robot (SOKO PRS-LRS-1218-H3), which stacked the pallet according to our specifications/sizes. Our video shows the entire dispatch line in operation.

The item offered here is the LOGOMATIK 415-T label applicator from LOGOPAK (highlighted with a blue circle in the layout image).

Summary of all relevant technical data for the LOGOMATIC 415 T labelling system:

• Machine type: LOGOMATIC 415 T.

• Print resolution: 300 dpi (12 dot).

Hedpexdcv Hsfx Af Isng

• Cycle capacity: Maximum 20 products per minute.

• Operation: HMI (10" colour LC display) in German.

• Signal light: 3-colour status light (red, blue, green) present.

• Frame: Standard frame with stainless steel spindle leveling feet (±50 mm adjustment).

• Certification: CE certified (EU).

• Mains voltage: 230V AC / 50 Hz (L,N,PE). Supply voltage should fluctuate by no more than ±5% and must be free from interference.

• Power consumption: Maximum approx. 1400 VA.

• Electrical connections at installation site: 1x Schuko socket for the labeler and 1x Schuko socket for maintenance purposes.

• Compressed air: 6 bar, dry and oil-free. The air supply must be permanently installed up to approx. 1 meter before the device.

• Compressed air consumption: Approx. 250 l/min.

• Compressed air connection: ½ inch permanent line with FESTO quick coupling KD4-½-A and coupling plug KS4-CK-6.

• Temperature: The ambient temperature for the labeler should be between +5°C and +37°C. For processing PE labels, 25°C is recommended.

• Applicator stroke length (net): 350 mm, defines the working area for different carton heights.

• Labelling height: 800 mm (standard setting).

• Orientation: Horizontally standing for top labelling.

• Label unwind/carrier take-up: For rolls up to 600 m running length.

• Label core adapter: 152 mm (6 inches).

• Current format (Amazon): 60 mm width x 40 mm height.

• Future shipping label: Approx. 100 mm width x 200 mm height. These dimensions can be varied depending on required label size.

• Label gap: 8 mm.

• Printing method: Thermal transfer.

• Label material: Paper labels (Paper Economy TT).

• Ribbon (TTR): Wax quality.

• Interface: Ethernet (10/100 Mbit). A serial RS-232C interface is also available.

• Data protocol: ZPL (Zebra).

• Data source: Host system.

• Data transmission: The data to be printed is sent from a PC to the labeler via Ethernet.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2025

Pateikti užklausą

Telefonas & Faksas

+49 160 9... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Würzburg

Würzburg

1 113 km

Etikečių spausdintuvas Etiketų spausdintuvas...

ZebraLegi-Air 4040Z-RH-500-110Pax-4

ZebraLegi-Air 4040Z-RH-500-110Pax-4

Mažas skelbimas

Skara

Skara

729 km

Kartoninės pakuotės mašina

SOCO SYSTEMt-55

SOCO SYSTEMt-55

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida