Plokščias štampas, karštasis spaudimas, multiGRAFOTRONIC

350 200254G

Plokščias štampas, karštasis spaudimas, multi

GRAFOTRONIC

350 200254G

Pradinė kaina neįskaitant PVM

67 500 €

Sąlyga

Naudotas

Vieta

Kruszyn Krajeński

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Plokščias štampas, karštasis spaudimas, multi

- Gamintojas:

- GRAFOTRONIC

- Modelis:

- 350 200254G

- Sąlyga:

- labai geros būklės (naudotas)

- Funkcionalumas:

- visiškai funkcionalus

Kaina ir vieta

Pradinė kaina neįskaitant PVM

67 500 €

- Vieta:

- Ceramiczna 15, 86-005 Białe Błota, PL

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A18949116

- Naujinta paskutinį kartą:

- Data 2025.12.29

Aprašymas

Segment I – Unwinder with Stabilizing Table

The first segment ensures stable web guidance. It is equipped with shafts that enable both lamination and delamination of the face material with the liner or other substrates. It features a laminator with precision pressure adjustment.

Additionally:

• A festoon mechanism in each segment enables continuous operation, eliminating the need to stop the machine during the operation of the flatbed die-cutter.

• Pulling servomotors provide precise material control and are also integrated in the station.

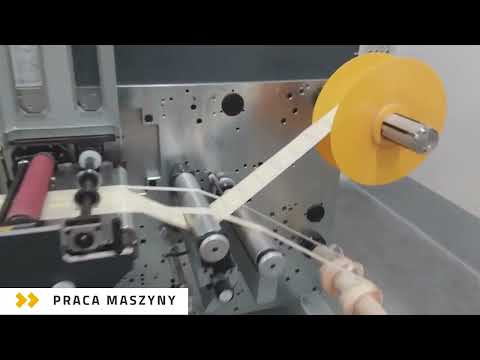

Segment II – Central (Die-Cutting Unit)

The heart of the machine is the flatbed die-cutter, designed for cutting and embossing.

It is equipped with:

• Hot stamping system – the heated plate with a mounted die allows the application of high-quality embellishments.

• Top unwinders for foil enable additional processing of the material.

• Manual pressure adjustment – four independent dials provide full process control, which is particularly important for irregular dies and non-standard jobs.

• Lower carriage as an alternative to the festoon system – used depending on the job specification.

Segment III – Puncher

The third segment is responsible for separating the cut labels and conveying them to the receiving tray.

• Puncher – precise separation of individual labels.

• Two laminators – one on each side of the puncher, with adjustable pressure settings.

• Unwinders and rewinders for smooth guidance of additional material.

Bodowck U Rjpfx Agijcw

Segment IV – Rewinder

The final segment is responsible for winding the finished material. Equipped with:

• Two shafts – allowing simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nip roller and tensioning roller) – ensuring stable material guidance.

• Slitting station with rotary knives.

• Matrix waste removal system.

• Web sensors located under each festoon for optimal process control.

Additional Features

• Remote control – the machine can be operated via the included tablet.

• Register mark sensor system – precisely aligns pre-printed material, guaranteeing high accuracy and repeatability of production.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

The first segment ensures stable web guidance. It is equipped with shafts that enable both lamination and delamination of the face material with the liner or other substrates. It features a laminator with precision pressure adjustment.

Additionally:

• A festoon mechanism in each segment enables continuous operation, eliminating the need to stop the machine during the operation of the flatbed die-cutter.

• Pulling servomotors provide precise material control and are also integrated in the station.

Segment II – Central (Die-Cutting Unit)

The heart of the machine is the flatbed die-cutter, designed for cutting and embossing.

It is equipped with:

• Hot stamping system – the heated plate with a mounted die allows the application of high-quality embellishments.

• Top unwinders for foil enable additional processing of the material.

• Manual pressure adjustment – four independent dials provide full process control, which is particularly important for irregular dies and non-standard jobs.

• Lower carriage as an alternative to the festoon system – used depending on the job specification.

Segment III – Puncher

The third segment is responsible for separating the cut labels and conveying them to the receiving tray.

• Puncher – precise separation of individual labels.

• Two laminators – one on each side of the puncher, with adjustable pressure settings.

• Unwinders and rewinders for smooth guidance of additional material.

Bodowck U Rjpfx Agijcw

Segment IV – Rewinder

The final segment is responsible for winding the finished material. Equipped with:

• Two shafts – allowing simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nip roller and tensioning roller) – ensuring stable material guidance.

• Slitting station with rotary knives.

• Matrix waste removal system.

• Web sensors located under each festoon for optimal process control.

Additional Features

• Remote control – the machine can be operated via the included tablet.

• Register mark sensor system – precisely aligns pre-printed material, guaranteeing high accuracy and repeatability of production.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+48 52 37... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1 237 km

"FGT Graphic Machinery" - Spausdinimo mašinos

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Mažas skelbimas

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1 212 km

Skaitmeninė spausdinimo mašina

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Mažas skelbimas

Bad Kreuznach

Bad Kreuznach

1 229 km

Fleksografinė spausdinimo mašina

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Mažas skelbimas

München

München

1 152 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Mažas skelbimas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

1 237 km

"FGT Graphic Machinery" - Spausdinimo mašinos

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Mažas skelbimas

Kaunas

Kaunas

30 km

Rewer

Jurmet

Jurmet

Mažas skelbimas

Dettelbach

Dettelbach

1 101 km

Sutraukimo įrenginys (kampinis suvirintojas + tunelis)

SmipackWS 560 A + T 450

SmipackWS 560 A + T 450

Mažas skelbimas

Vokietija

Vokietija

999 km

Etikečių klijavimo mašina

GMLA 330

GMLA 330

Mažas skelbimas

파주시

파주시

7 381 km

Tobulas įrišėjas (Perfect Binder)

HorizonBQ-270

HorizonBQ-270

Mažas skelbimas

Bischofszell

Bischofszell

1 325 km

PATIKRINIMO RITE

R.P.E.LRKP 350 MIT SCHNEIDEEINRICHTUNG

R.P.E.LRKP 350 MIT SCHNEIDEEINRICHTUNG

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida