Baleninė su išankstinio presavimo sklende LP 50 EH1Balerio su prepresavimo sklende LP 50 EH1Presona AB

LP 50 EH1

Baleninė su išankstinio presavimo sklende LP 50 EH1Balerio su prepresavimo sklende LP 50 EH1

Presona AB

LP 50 EH1

Gamybos metai

2005

Sąlyga

Naudotas

Vieta

Nyderlandai

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Baleninė su išankstinio presavimo sklende LP 50 EH1Balerio su prepresavimo sklende LP 50 EH1

- Gamintojas:

- Presona AB

- Modelis:

- LP 50 EH1

- Gamybos metai:

- 2005

- Sąlyga:

- dilaminuotas dirbtuvėje (naudotas)

- Funkcionalumas:

- visiškai funkcionalus

- Darbo valandos:

- 30 408 h

Kaina ir vieta

- Vieta:

- , Nyderlandai

Skambinti

Techniniai duomenys

- Spaudimo jėga:

- 50 t

- Pildymo angos plotis:

- 1 100 mm

- Pildymo angos ilgis:

- 1 250 mm

- Ryšulio plotis:

- 1 100 mm

- Ryšulio aukštis:

- 720 mm

- Balo svoris:

- 550 kg

- Bendras svoris:

- 16 000 kg

- Alyvos bako talpa:

- 600 l

- Paskutinio kapitalinio remonto metai:

- 2024

Pasiūlymo informacija

- Sąrašo ID:

- A17766606

- Naujinta paskutinį kartą:

- Data 2025.06.20

Aprašymas

Technical Data – Baler:

Manufacturer: Presona AB

Model: LP 50 EH1

Year of manufacture: 2005

Operating hours: 30,408 hours (as of April)

Njdsu Thhrepfx Af Iekt

Number of bales pressed: 198,059 units (as of April)

Main press ram force: 50 t

Specific pressing force: 63 N/cm²

Theoretical throughput: 530 m³/hour

Throughput under operating conditions: 260 m³/hour

Feed chute dimensions: 1,250 x 1,100 mm

Press chamber volume: 2.2 m³

Bale dimensions: 1,100 x 720 mm, length variable

Drive power: 22 kW

Tying: 5-fold vertical, fully automatic

Throughput rates at a bulk density of:

- 30 kg/m³: 6 to 7 t/hour

- 50 kg/m³: 7 to 9 t/hour

- 100 kg/m³: 11 to 14 t/hour

Bale density (paper/newspapers): 400 to 550 kg/m³

Hydraulic oil tank capacity: 600 L

PLC: Telemecanique TSX Micro

Operator panel: Schneider Magelis

Effective transport dimensions excl. press: 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight (press only): approx. 16 t

Condition of the baler:

The machine underwent partial refurbishment and general maintenance in our workshop. After completion of the refurbishment, the baler was tested in operational mode and is now available for immediate sale.

The following refurbishments were carried out:

General work:

- Machine cleaned, derusted, primed, and partially repainted

- Wire entry marks in the press channel openings welded and smoothed

Hydraulic unit:

- Hydraulic oil tank fully drained, cleaned, and refilled with new oil

- Oil and air filters replaced

- Leaking oil sight glass on the hydraulic tank replaced

- All hydraulic hoses replaced

Electrical system:

- Program menu language set to English

- Two key switches on the operator panel replaced

- Control cabinet replaced

- Signal lamp on the control cabinet replaced

- Flap limit switch replaced

- Wirthulator electrics renewed, connected, and tested

Press ram:

- All four guide rollers on the press ram removed and replaced

- Main hydraulic cylinder disassembled, overhauled (cylinder tube honed, complete seal kit replaced), leak test performed

- All wear-resistant plastic blocks on the press ram replaced

Pre-press flap:

- Both bearings on the pre-press shaft replaced

- Both hydraulic cylinders disassembled, overhauled (cylinder tubes honed, complete seal kits replaced), leak test performed

- Scraper flap on the pre-press replaced

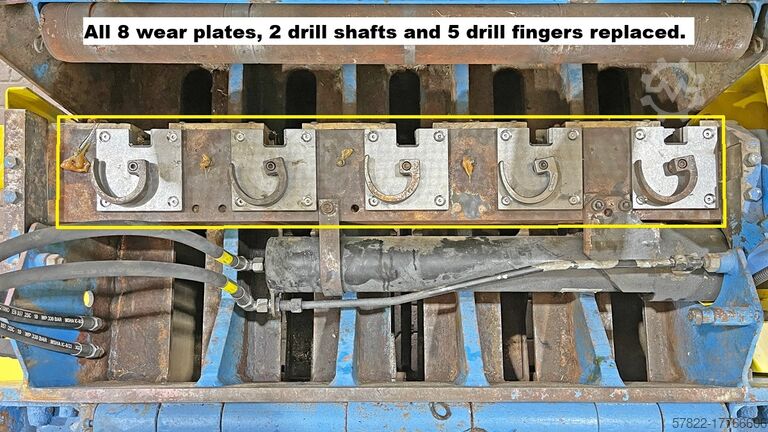

Tying unit:

- Two complete needles with wire guide pulleys replaced

- Needles adjusted and set

- All wire guide pulleys in needle heads replaced

- Twisting fingers replaced

- Two twister shafts replaced

- All eight wear plates on the twister unit, under the twisting fingers, replaced

Scope of delivery:

Only the baler is sold.

Documentation (operating instructions, CE declaration, electrical/hydraulic circuit diagrams) is complete and available. Inspection by appointment possible. We do not accept liability for the technical data or possible errors.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Manufacturer: Presona AB

Model: LP 50 EH1

Year of manufacture: 2005

Operating hours: 30,408 hours (as of April)

Njdsu Thhrepfx Af Iekt

Number of bales pressed: 198,059 units (as of April)

Main press ram force: 50 t

Specific pressing force: 63 N/cm²

Theoretical throughput: 530 m³/hour

Throughput under operating conditions: 260 m³/hour

Feed chute dimensions: 1,250 x 1,100 mm

Press chamber volume: 2.2 m³

Bale dimensions: 1,100 x 720 mm, length variable

Drive power: 22 kW

Tying: 5-fold vertical, fully automatic

Throughput rates at a bulk density of:

- 30 kg/m³: 6 to 7 t/hour

- 50 kg/m³: 7 to 9 t/hour

- 100 kg/m³: 11 to 14 t/hour

Bale density (paper/newspapers): 400 to 550 kg/m³

Hydraulic oil tank capacity: 600 L

PLC: Telemecanique TSX Micro

Operator panel: Schneider Magelis

Effective transport dimensions excl. press: 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight (press only): approx. 16 t

Condition of the baler:

The machine underwent partial refurbishment and general maintenance in our workshop. After completion of the refurbishment, the baler was tested in operational mode and is now available for immediate sale.

The following refurbishments were carried out:

General work:

- Machine cleaned, derusted, primed, and partially repainted

- Wire entry marks in the press channel openings welded and smoothed

Hydraulic unit:

- Hydraulic oil tank fully drained, cleaned, and refilled with new oil

- Oil and air filters replaced

- Leaking oil sight glass on the hydraulic tank replaced

- All hydraulic hoses replaced

Electrical system:

- Program menu language set to English

- Two key switches on the operator panel replaced

- Control cabinet replaced

- Signal lamp on the control cabinet replaced

- Flap limit switch replaced

- Wirthulator electrics renewed, connected, and tested

Press ram:

- All four guide rollers on the press ram removed and replaced

- Main hydraulic cylinder disassembled, overhauled (cylinder tube honed, complete seal kit replaced), leak test performed

- All wear-resistant plastic blocks on the press ram replaced

Pre-press flap:

- Both bearings on the pre-press shaft replaced

- Both hydraulic cylinders disassembled, overhauled (cylinder tubes honed, complete seal kits replaced), leak test performed

- Scraper flap on the pre-press replaced

Tying unit:

- Two complete needles with wire guide pulleys replaced

- Needles adjusted and set

- All wire guide pulleys in needle heads replaced

- Twisting fingers replaced

- Two twister shafts replaced

- All eight wear plates on the twister unit, under the twisting fingers, replaced

Scope of delivery:

Only the baler is sold.

Documentation (operating instructions, CE declaration, electrical/hydraulic circuit diagrams) is complete and available. Inspection by appointment possible. We do not accept liability for the technical data or possible errors.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Dokumentai

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+31 597 2... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Vokietija

Vokietija

872 km

Presas

DIXI40 SLK

DIXI40 SLK

Mažas skelbimas

Nyderlandai

Nyderlandai

1 127 km

Presas su 8 kartus kryžminiu rišimu

Presona ABLP 80 VHK 1

Presona ABLP 80 VHK 1

Mažas skelbimas

Kaufungen

Kaufungen

1 042 km

Standartinis vilkikas

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

Mažas skelbimas

Wuppertal

Wuppertal

1 199 km

Perdirbimo ekstruderis - granuliavimo įrenginys / kaskada

AGRIFONAM-145

AGRIFONAM-145

Mažas skelbimas

Tata

Tata

923 km

Kanalų presas Pal Pacomat V 50t

PAAL PACOMAT V50ton 500kg bale

PAAL PACOMAT V50ton 500kg bale

Mažas skelbimas

Karlholmsbruk

Karlholmsbruk

701 km

Chipper

Söderhamn Eriksson670-56

Söderhamn Eriksson670-56

Mažas skelbimas

Fohnsdorf

Fohnsdorf

1 092 km

Metalo laužo presas

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

Mažas skelbimas

Lagedi

Lagedi

475 km

Spaudos konteineris

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

Mažas skelbimas

Lagedi

Lagedi

475 km

Stiklinės spaudos indas

HusmannSI- SEL- V2

HusmannSI- SEL- V2

Mažas skelbimas

Braniewo

Braniewo

275 km

Angaro konstrukcija

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida