Metalski Zavod Tito pirkti naudotą (110)

Rikiuoti rezultatus

- Žemiausia kaina Aukščiausia kaina

- Naujausi skelbimai Seniausi skelbimai

- Trumpiausias atstumas Didžiausias atstumas

- Naujausi metai gamybos Seniausi gamybos metai

- Naujausias atnaujinimas Seniausias atnaujinimas

- Gamintojai nuo A iki Z Gamintojas nuo Z iki A

- Aktualumas

- Žemiausia kaina

- Kaina

- Aukščiausia kaina

- Kaina

- Naujausi skelbimai

- Nurodyta data

- Seniausi skelbimai

- Nurodyta data

- Trumpiausias atstumas

- Atstumas

- Didžiausias atstumas

- Atstumas

- Naujausi metai gamybos

- Gamybos metai

- Seniausi gamybos metai

- Gamybos metai

- Naujausias atnaujinimas

- Naujinta paskutinį kartą

- Seniausias atnaujinimas

- Naujinta paskutinį kartą

- Gamintojai nuo A iki Z

- Gamintojas

- Gamintojas nuo Z iki A

- Gamintojas

- Pavadinimas nuo A iki Z

- Pavadinimas

- Pavadinimas nuo Z iki A

- Pavadinimas

- Modelis nuo A iki Z

- Modelis

- Modelis nuo Z iki A

- Modelis

- Žemiausia nuoroda

- nuoroda

- Aukščiausia nuoroda

- nuoroda

- Trumpiausias veikimo laikas

- Veikimo laikas

- Ilgiausia veikimo trukmė

- Veikimo laikas

- Aktualumas

- Aktualumas

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton360 Plus (DUAL)

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 150 kg, kuro tipas: dyzelinas, bakelio talpa: 15 l, spalva: juodas, išėjimo srovė: 15 A, išėjimo įtampa: 400 V, išėjimo dažnis: 50 Hz, nominali galia: 8,5 kW (11,56 AG), nuolatinė galia: 7,6 kW (10,33 AG), bendras ilgis: 750 mm, bendras plotis: 650 mm, bendras aukštis: 730 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, Diesel Generator Set with 8.5kW Power Output. The Proton 360 Plus features Dual Power technology, allowing the user to access 80% of total output on the single-phase socket and 100% output on the three-phase socket.

SUMMARY:

Generator type: DUAL, Single-phase, Three-phase

Fuel type: Diesel

Air-cooled: Yes

Voltage: 230/400V

Rated power: 400V – 7,600 Watts (9.5 kVA)

Maximum power (up to 15 minutes): 8,500 Watts (10.6 kVA)

Rated power at 230V: 6,000 Watts

Maximum power (up to 15 minutes): 6,800 Watts

WEIGHT:

Gross weight: 150 kg

FUEL CONSUMPTION:

1.7 litres/hour (at 70% maximum load)

2.1 litres/hour (at 90% maximum load)

TECHNICAL DATA:

Ready for operation – Yes

Type – Portable

Year of manufacture – 2024

Condition – Brand new

Manufacturer – Proton

Warranty – 24 months

Efficiency cos Φ – 0.8

ENGINE:

Engine model – Proton 192FA-D0

Fuel type – Diesel

Engine type – Diesel, 4-stroke

Number of cylinders – 1

Direct injection – Yes

Cooling – Air

Displacement – 499 cc

RPM – 3,000

Max continuous run time (1 cycle) – 8 hours

Cooling down time (after 1 cycle) – 60 minutes

Oil pressure and level sensor – Yes

Valve actuation – Gear drive

Engine speed control – Mechanical governor

Lubrication – Forced lubrication, oil pump

Starter – 800W

Oil sump capacity – 1.7 litres

Itodpfxstrl A Ae Af Iob

Recommended oil – TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type – Electromagnetic, operated by single solenoid

ALTERNATOR:

Alternator model – Proton 190-CAVR-D

Rated current (400V) – 15.0 A

Voltage – 230/400V

Frequency – 50 Hz

Alternator construction – Synchronous

Protection rating – IP 23

HOUSING:

Construction type – Open frame

Exhaust outlet option – Yes

Sound pressure level LPA – 86dB (measured at 5m, open field)

Fuel tank capacity – 15 litres

Average runtime per tank – 8 hours

SOCKETS:

Number of three-phase sockets – 1 (16A, 5-pin)

Number of single-phase sockets – 1 (32A), 2 (16A)

Other sockets – 1 (12V)

DIMENSIONS:

Wheel diameter – 22 cm

Width – 65 cm

Length – 75 cm

Height – 73 cm

FEATURES:

DualPower™ technology – Yes

Automatic transfer switch (ATS) – Ready

Voltage regulator (AVR) – Built-in

Remote control – Yes (up to 90m in open space)

Starter type – Electric

Glow plugs – Yes

Fuel gauge – Yes

Voltmeter – Yes

Ammeter – Yes

Circuit protection – 3xC16 (for 400V), 1xC32 (for 230V)

Hour meter – Yes

Battery – 36 Ah

Transport kit:

Yes – Large wheels

Yes – Handles

EXTENSIVE EQUIPMENT

See below what the set includes:

• Battery

• Air, oil, and fuel filters

• Maintenance tools

• Plugs

Why choose our company?

We are a company specialising exclusively in generator sets, with over 17 years of continuous experience in the industry, consistently striving to ensure our products represent the highest quality and reliability. We offer a wide range of generator sets from 6 to 300kW, equipped with a variety of engines including English Ricardo, American Cummins, and German Deutz, and in multiple configurations tailored to customer requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton360 (DUAL)

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 143 kg, kuro tipas: dyzelinas, bakelio talpa: 12 l, spalva: juodas, išėjimo srovė: 12 A, išėjimo įtampa: 400 V, išėjimo dažnis: 50 Hz, nominali galia: 6,8 kW (9,25 AG), nuolatinė galia: 6,2 kW (8,43 AG), bendras ilgis: 730 mm, bendras plotis: 500 mm, bendras aukštis: 620 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, Diesel Generator Set with 6.8kW Output. The Proton 360 features Dual Power technology, allowing users to obtain 80% of power on the single-phase socket and 100% of power on the three-phase socket.

SUMMARY:

Generator type: DUAL, Single-phase, Three-phase

Fuel type: Diesel

Air-cooled: Yes

Voltage: 230/400V

Rated output: 400V - 6200 Watts (7.7kVA)

Maximum output (up to 15 minutes): 6800W (8.5kVA)

Rated output 230V: 4960 Watts

Maximum output (up to 15 minutes): 5440 Watts

WEIGHT:

Gross weight: 143 kg

FUEL CONSUMPTION:

Itsdpfotq Upiox Af Ieb

1.0 liters per hour (at 70% maximum load)

1.2 liters per hour (at 90% maximum load)

TECHNICAL DATA:

Ready for operation: Yes

Type: Portable

Year of manufacture: 2024

Condition: Brand new

Manufacturer: Proton

Warranty: 24 months

Power factor cos Φ: 0.8

ENGINE:

Engine model: Proton 188FA-D

Fuel type: Diesel fuel

Engine type: Diesel, 4-stroke

Number of cylinders: 1

Direct injection: Yes

Cooling type: Air

Displacement: 456 cc (88x75)

RPM: 3000

Allowed maximum operating time (1 cycle): 8 hours

Cooling time (after 1 cycle): 60 minutes

Oil pressure and level sensor: Yes

Valve timing: Gear-driven

governor: Mechanical

Lubrication: Forced lubrication with oil pump

Starter: 800W

Oil sump capacity: 1.6L

Recommended oil: TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type: Electromagnetic, controlled by single solenoid

ALTERNATOR:

Alternator model: Proton 180-CAVR-D

Rated current (400V): 12.3 A

Voltage: 230/400V

Frequency: 50 Hz

Construction: Synchronous

Protection class: IP 23

HOUSING:

Canopy type: Open frame

Exhaust gas venting option: Yes

Sound pressure level LPA: 84dB (measured at 5m, open space)

Fuel tank capacity: 12 liters

Average runtime on full tank: 8 hours

SOCKETS:

Number of three-phase sockets: 1 pc (16A, 5-pin)

Number of single-phase sockets: 1 pc (32A), 1 pc (8A)

Other sockets: 1 pc (12V)

DIMENSIONS:

Wheel diameter: 22 cm

Width: 50 cm

Length: 73 cm

Height: 62 cm

FEATURES:

DualPower™ technology: Yes

Automatic start (ATS-ready): Yes

Voltage stabilizer (AVR): Yes - integrated

Remote control: Yes (up to 90m in open space)

Starting system: Electric

Glow plugs: Yes

Fuel level indicator: Yes

Voltmeter: Yes

Ammeter: Yes

Circuit protection: 3xC16 (for 400V), 1xC32 (for 230V)

Hour meter: Yes

Battery: 36 Ah

Transport kit:

Yes - Large wheels

Yes - Handles

RICH EQUIPMENT PACKAGE

See below for set contents:

• Battery

• Air, oil, and fuel filters

• Basic service tools

• Plugs

About our company

We are a company specializing exclusively in power generators, with over 17 years of experience in the industry. We are continuously striving to ensure our products represent the highest quality and reliability. Our range includes generators from 6 to 300kW with various engines including UK-manufactured Ricardo, US Cummins, and German Deutz, as well as different configurations tailored to customer requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

ProtonOasis 360 Plus (DUAL)

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 175 kg, kuro tipas: dyzelinas, bakelio talpa: 15 l, spalva: juodas, išėjimo srovė: 15 A, išėjimo įtampa: 400 V, išėjimo dažnis: 50 Hz, nominali galia: 8,5 kW (11,56 AG), nuolatinė galia: 7,6 kW (10,33 AG), bendras ilgis: 920 mm, bendras plotis: 520 mm, bendras aukštis: 720 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, Diesel Generator Set with 8.5kW Power Output. The Proton 360 Plus features Dual Power technology, allowing the user to achieve 80% of total power via the single-phase outlet and full 100% power via the three-phase socket.

SUMMARY:

Generator type: DUAL, Single-phase, Three-phase

Fuel type: Diesel

Air-cooled: Yes

Voltage: 230/400V

Rated output: 400V – 7600 Watts (9.5kVA)

Maximum output for up to 15 minutes – 8500W (10.6 kVA)

Rated output 230V – 6000 Watts

Maximum output for up to 15 minutes – 6800 Watts

WEIGHT:

Gross Weight: 175 kg

FUEL CONSUMPTION:

1.7 litres per hour (at 70% max load)

2.1 litres per hour (at 90% max load)

TECHNICAL DATA:

Ready-to-use – Yes

Type – Portable

Year of manufacture – 2024

Generator condition – Brand new

Manufacturer – Proton

Warranty – 24 months

Efficiency cos Φ – 0.8

ENGINE:

Engine model – Proton 192FA-D0

Fuel type – Diesel

Engine type – Diesel, 4-stroke

Number of cylinders – 1

Direct injection – Yes

Cooling type – Air

Displacement – 499 cm3

RPM – 3000

Maximum permissible continuous run time (1 cycle) – 6 hours

Cooling time (after 1 cycle) – 60 minutes

Oil pressure and level sensor – Yes

Valve timing type – Gear-driven OHV

Engine speed regulator – Mechanical

Lubrication system – Forced lubrication (oil pump)

Starter – 800W

Oil sump capacity – 1.7l

Recommended oil – TITAN CARGO MC 10W40 (diesel semi-synthetic)

Valve type – Electromagnetic, activated by single solenoid

ALTERNATOR:

Alternator model – Proton 190-CAVR-D

Rated current (400V) – 15.0 A

Voltage – 230/400V

Frequency – 50 Hz

Alternator design – Synchronous

Protection class (alternator) – IP 23

ENCLOSURE:

Enclosure type – Enclosed – Soundproofed

External exhaust option – Yes

Sound pressure level LPA – 72dB (measured at 5m, open space)

Fuel tank capacity – 15 litres

Average runtime on full tank – 8 hours

OUTLETS:

Number of three-phase outlets – 1 x (16A, 5-pin)

Single-phase outlets – 1 x (32A), 2 x (16A)

Iodotrl D Dopfx Af Istb

Auxiliary outlets – 1 x (12V)

DIMENSIONS:

Wheel diameter – 10 cm

Width – 52 cm

Length – 92 cm

Height – 72 cm

FEATURES:

DualPower™ technology – Yes

Automatic start (ATS) – Yes, compatible

Voltage regulator (AVR) – Yes, built-in

Remote control – Yes (up to 90m, open space)

Starting method – Electric

Glow plugs – Yes

Fuel gauge – Yes

Voltmeter – Yes

Ammeter – Yes

Circuit breakers – 3xC16 (400V), 1xC32 (230V)

Hour meter – Yes

Battery – 36 Ah

Transport kit:

Yes – Small wheels

Yes – Handles on both sides

RICH STANDARD EQUIPMENT

See below for what's included:

• Battery

• Air, oil, and fuel filters

• Tools for routine maintenance

• Plugs

Why choose our company?

We are a specialist company exclusively focused on generator sets, operating in the industry for over 17 years. Our aim has always been to offer products of the highest quality and maximum reliability. We provide a comprehensive range of generators from 6 to 300kW, powered by various engine brands including British Ricardo, American Cummins, and German Deutz, as well as different configurations tailored to client requirements.

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton1 Plus

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 150 kg, kuro tipas: dyzelinas, bakelio talpa: 15 l, spalva: juodas, išėjimo srovė: 46 A, išėjimo įtampa: 230 V, išėjimo dažnis: 50 Hz, nominali galia: 8,5 kW (11,56 AG), nuolatinė galia: 7,6 kW (10,33 AG), bendras ilgis: 750 mm, bendras plotis: 650 mm, bendras aukštis: 730 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, The reliable Proton 1 Plus power generator is equipped with increased output thanks to a larger engine and alternator. To ensure optimal operation, we have reinforced the entire generator structure. This generator is ideal for both commercial and residential applications.

SUMMARY:

Generator type: Single-phase

Fuel type: Diesel

Air-cooled: Yes

Voltage: 230 V

Rated power: 230 V - 7,600 Watt (9.5 kVA)

Maximum power (up to 15 min): 8,500W (10.6 kVA)

WEIGHT:

Gross weight: 150 kg

FUEL CONSUMPTION:

1.7 liters per hour (at 70% maximum load)

2.1 liters per hour (at 90% maximum load)

TECHNICAL DATA:

Ready for operation - Yes

Type - Portable

Year of manufacture - 2024

Condition - Brand new

Manufacturer - Proton

Warranty - 24 months

Power factor cos Φ - 0.8

ENGINE:

Engine model - Proton 192FA-D0

Fuel type - Diesel

Engine type - Diesel, 4-stroke

Number of cylinders - 1

Direct injection - Yes

Cooling type - Air

Displacement - 499 cc3

Engine speed (RPM) - 3,000

Permissible maximum run time (per cycle) - 8 hours

Cooling time (after 1 cycle) - 60 minutes

Oil pressure and level sensor - Yes

Valve timing - Gear-driven

Engine speed governor - Mechanical

Lubrication system - Forced, oil pump engine

Starter motor - 800W

Oil pan capacity - 1.7L

Recommended oil - TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type - Electromagnetic, controlled by a single solenoid

ALTERNATOR:

Alternator model - Proton 190-CAVR-230

Rated current (230V) – 46.0 A

Voltage – 230V

Frequency – 50 Hz

Alternator design – Synchronous

Protection class (alternator) – IP 23

CASING:

Enclosure type – Open frame

Exhaust outlet option – Yes

Sound pressure level LPA – 86dB (measured at 5m, open space)

Fuel tank capacity – 15 liters

Average runtime on full tank – 8 hours

Itedpfxstrmule Af Iob

SOCKETS:

Three-phase sockets – None

Single-phase sockets – 1 x 32A, 2 x 16A

Auxiliary outlets – 1 x 12V

DIMENSIONS:

Wheel diameter – 22 cm

Width – 65 cm

Length – 75 cm

Height – 73 cm

FEATURES:

DualPower™ technology – Yes

Automatic start (ATS) – Yes, compatible

Voltage stabilizer (AVR) – Yes, integrated

Remote control – Yes (up to 90m in open area)

Starter type – Electric, recoil (manual)

Glow plugs – Yes

Fuel level indicator – Yes

Voltmeter – Yes

Ammeter – Yes

Circuit breakers – 1xC32 (for 230V)

Hour meter – Yes

Battery – 36 Ah

Transport kit:

Large wheels – Yes

Handles – Yes

COMPREHENSIVE EQUIPMENT

See below for what else is included:

• Battery

• Air, oil, and fuel filters

• Service tools

• Plugs

Why choose our company?

We are a company specializing exclusively in power generators, with over 17 years of experience in the industry, constantly striving to ensure our products represent the highest quality and maximum reliability. We offer a wide range of generators from 6 to 300 kW, powered by various engines including British Ricardo, American Cummins, or German Deutz, available in custom configurations tailored to customer requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton3 Plus

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 150 kg, kuro tipas: dyzelinas, bakelio talpa: 15 l, spalva: juodas, išėjimo srovė: 15 A, išėjimo įtampa: 400 V, išėjimo dažnis: 50 Hz, nominali galia: 8,5 kW (11,56 AG), nuolatinė galia: 7,6 kW (10,33 AG), bendras ilgis: 750 mm, bendras plotis: 650 mm, bendras aukštis: 730 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, Powerful Proton 3 Plus Generator – Special Purpose High-Power Generator

The Proton 3 Plus generator is engineered for demanding applications requiring increased output, delivering a peak power of 8,500W thanks to its new engine and alternator. For safe operation, the frame has been reinforced.

SUMMARY:

Generator type: Three-phase

Fuel type: Diesel

Air-cooled: Yes

Isdjtrmfaopfx Af Ijtb

Voltage: 230/400V

Rated power output: 400V – 7,600 Watts (9.5 kVA)

Maximum power (up to 15 minutes): 8,500W (10.6 kVA)

WEIGHT:

Gross weight: 150 kg

FUEL CONSUMPTION:

1.7 litres/hour (at 70% max power)

2.1 litres/hour (at 90% max power)

TECHNICAL DATA:

Ready to operate: Yes

Type: Portable

Year of manufacture: 2024

Generator condition: Brand new

Manufacturer: Proton

Warranty: 24 months

Efficiency cos Φ: 0.8

ENGINE:

Engine model: Proton 192FA-D0

Fuel type: Diesel

Engine type: Diesel, 4-stroke

Number of cylinders: 1

Direct injection: Yes

Cooling type: Air-cooled

Displacement: 499 cc

RPM: 3000

Maximum continuous operation per cycle: 8 hours

Cooling time (per cycle): 60 minutes

Oil pressure and level sensor: Yes

Valve timing type: Gear-driven OHV

Engine speed governor: Mechanical

Lubrication system: Forced lubrication with oil pump

Starter motor: 800W

Oil sump capacity: 1.7 l

Recommended oil: TITAN CARGO MC 10W40 (semi-synthetic, diesel)

Valve type: Electromagnetic, solenoid controlled

ALTERNATOR:

Alternator model: Proton 190-CAVR-400

Rated current (400V): 15.0 A

Voltage: 400V

Frequency: 50 Hz

Construction: Synchronous

Protection rating: IP23

FRAME/HOUSING:

Type: Open-frame (non-enclosed)

External exhaust port: Yes

Sound pressure level LPA: 86 dB (measured at 5m, open area)

Fuel tank capacity: 15 litres

Operating time at full tank (average): 8 hours

OUTLETS:

Three-phase outlets: 1 (16A, 5-pin)

Single-phase outlets: 3 (8A)

Auxiliary outlets: 1 (12V)

DIMENSIONS:

Wheel diameter: 22 cm

Width: 65 cm

Length: 75 cm

Height: 73 cm

FUNCTIONS:

DualPower™ technology: Yes

Automatic start (ATS): Yes – compatible

Voltage stabilizer (AVR): Yes – built-in

Remote control: Yes (up to 90m in open space)

Starting types: Electric, Manual (recoil)

Glow plugs: Yes

Fuel level indicator: Yes

Voltmeter: Yes

Ammeter: Yes

Circuit breakers: 3xC16 (for 400V)

Hour meter: Yes

Battery: 36 Ah

Transport kit:

Included – large wheels

Included – handles

EXTENSIVE EQUIPMENT

See what is included in the set below:

• Battery

• Air, oil, and fuel filters

• Service tools

• Plugs

Why choose us?

We are a company specializing exclusively in power generators, operating in the industry for over 17 years. Our mission is to provide top-quality, highly reliable products. Our wide range covers generator sets from 6 to 300kW using engines such as English Ricardo, American Cummins, or German Deutz, in multiple configurations tailored to customer requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton1

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 141 kg, kuro tipas: dyzelinas, bakelio talpa: 12 l, spalva: juodas, išėjimo srovė: 40 A, išėjimo įtampa: 230 V, išėjimo dažnis: 50 Hz, nominali galia: 7,5 kW (10,20 AG), nuolatinė galia: 7 kW (9,52 AG), bendras ilgis: 730 mm, bendras plotis: 500 mm, bendras aukštis: 620 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: oras, Portable Diesel Generator Proton 1 with Comprehensive Equipment – Complete Functionality and Energy Independence. Equipped with a reliable engine for trouble-free start-up and extended generator lifespan. An excellent generator for home or business use.

SUMMARY:

Generator Type: Single-phase

Fuel Type: Diesel

Air-cooled: Yes

Voltage: 230V

Rated Power: 230V – 7000 Watts (8.75kVA)

Max Power (up to 15 min): 7500W (9.4kVA)

WEIGHT:

Gross Weight: 141 kg

FUEL CONSUMPTION:

1.0 litres per hour (at 70% of max load)

1.2 litres per hour (at 90% of max load)

TECHNICAL DATA:

Ready to operate – Yes

Type – Portable

Year of manufacture – 2024

Generator condition – Brand new

Manufacturer – Proton

Warranty – 24 months

Efficiency cos Φ – 0.8

ENGINE:

Engine model – Proton 188FA-D

Fuel type – Diesel

Engine type – Diesel, 4-stroke

Number of cylinders – 1

Direct injection – Yes

Cooling type – Air

Displacement – 478 cc3

RPM – 3000

Permissible max runtime (per cycle) – 8 hours

Cooling time (after 1 cycle) – 60 minutes

Oil pressure and level sensor – Yes

Valve drive type – Gear driven

Speed regulator – Mechanical

Lubrication method – Forced, engine with oil pump

Starter – 800W

Oil sump capacity – 1.6L

Recommended oil – TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type – Electromagnetic, single coil controlled

ALTERNATOR:

Alternator model – Proton 180-CAVR-230

Rated current (230V) – 40 A

Voltage – 230 V

Frequency – 50 Hz

Construction – Synchronous

Protection class (alternator) – IP23

HOUSING:

Enclosure type – Open frame

Exhaust outlet option – Yes

Sound pressure level LPA – 84dB (measured at 5m, open field)

Fuel tank capacity – 12 litres

Operating time on full tank (average) – 8 hours

SOCKETS:

Number of three-phase sockets – None

Number of single-phase sockets – 1x (32A), 2x (16A)

Additional sockets – 1x (12V)

DIMENSIONS:

Wheel diameter – 22 cm

Width – 50 cm

Length – 73 cm

Height – 62 cm

FEATURES:

DualPower™ technology – Yes

Automatic transfer switch (ATS ready) – Yes

Voltage regulator (AVR) – Yes, built-in

Remote control – Yes (up to 90m, open space)

Starting method – Electric, Manual (recoil)

Glow plugs – Yes

Fuel level indicator – Yes

Voltmeter – Yes

Ammeter – Yes

Circuit protection – 1xC32 (for 230V)

Hour meter – Yes

Battery – 36 Ah

Transport kit:

Yes – Large wheels

Yes – Handles

RICH EQUIPMENT PACKAGE

See below for included accessories:

• Battery

• Air, oil, and fuel filters

• Operating tools

Itsdpfx Astrmhrjf Ijb

• Plugs

Why choose our company?

We are a company specializing exclusively in generators, operating in this industry for over 17 years, consistently striving to ensure our products represent the highest quality and maximum reliability. We offer a wide range of generators from 6 to 300kW with a variety of engines, including British Ricardo, American Cummins, and German Deutz, available in various configurations tailored to client requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton12000 230

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, bendras svoris: 260 kg, kuro tipas: dyzelinas, bakelio talpa: 34 l, spalva: juodas, išėjimo srovė: 65 A, išėjimo įtampa: 230 V, išėjimo dažnis: 50 Hz, nominali galia: 12 kW (16,32 AG), nuolatinė galia: 10 kW (13,60 AG), bendras ilgis: 930 mm, bendras plotis: 660 mm, bendras aukštis: 900 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: vanduo, Model Proton 12000 230V is a single-phase generator with a maximum output of 12 kW. This generator is equipped with a radiator, which allows for continuous operation of up to 24 hours. It features a built-in AVR voltage regulator.

SUMMARY:

Generator type: Single-phase

Liquid-cooled: Yes

Fuel type: Diesel

Voltage: 230V

Rated output: 230V - 10,000 Watts (12.5 kVA)

Maximum output (up to 15 minutes): 12,000 Watts (15 kVA)

WEIGHT:

Gross weight: 260 kg

FUEL CONSUMPTION:

2.2 liters per hour (at 70% maximum power)

1.8 liters per hour (at 40% maximum power)

TECHNICAL DATA:

Ready for operation: Yes

Type: Portable

Year of manufacture: 2024

Generator condition: Brand new

Manufacturer: Proton

Warranty: 24 months

Power factor cos φ: 0.8

ENGINE:

Engine model: Proton 2V8-W

Fuel type: Diesel

Engine type: Diesel, 4-stroke

Number of cylinders: 2

Direct injection: Yes

Cooling system: Liquid-cooled (includes radiator)

Engine displacement: 998 cc

Rated speed (RPM): 3,000

Permitted maximum operating time (per cycle): 24 hours

Cooling time (after 1 cycle): 60 minutes

Oil pressure sensor: Yes

Oil level sensor: Yes

Valve timing: Gear-driven

Engine speed governor: Mechanical

Lubrication system: Forced lubrication with oil pump

Starter: 1,100W

Oil sump capacity: 2.5 l

Recommended oil: TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type: Electromagnetic, single solenoid controlled

ALTERNATOR:

Alternator model: Proton 220-CAVR-D

Rated current (230V): 65 A

Voltage: 230V

Frequency: 50 Hz

Alternator type: Synchronous

Protection class (alternator): IP 23

HOUSING:

Enclosure type: Open

Possibility to exhaust outside: Yes

Noise level LPA: 85 dB (measured at 5m, open area)

Fuel tank capacity: 34 liters

Average operating time on full tank: 12 hours

OUTLETS:

Number of three-phase sockets: none

Number of single-phase sockets: 1 x 32A, 1 x 16A

Other outlets: none

DIMENSIONS:

Wheel diameter: 10 cm

Width: 66 cm

Length: 93 cm

Height: 90 cm

FEATURES:

DualPower™ technology: Yes

Automatic transfer switch (ATS): Yes - compatible

Voltage stabilizer (AVR): Yes - built-in

Remote control: No

Starting method: Electric

Glow plugs: Yes

Fuel level indicator: Yes

Voltmeter: Yes

Ammeter: Yes

Circuit protection: 1xC39 (for 230V)

Hour meter: Yes

Battery: 45 Ah

Itodpfxstq Hggo Af Ieb

TRANSPORT KIT:

Yes - Small wheels

Yes - Side handles

Yes - Swivel wheels

Yes - Lockable wheels

EXTENSIVE EQUIPMENT

See below what else is included in the package:

• Battery

• Air filter

• Oil filter

• Fuel filter

• Maintenance tools

• Plugs

Why choose our company?

We are a company specializing exclusively in power generators, operating in this sector for over 17 years, constantly striving to ensure our products represent the highest quality and reliability. We offer a wide range of generators from 6 to 300 kW, with various engines including UK-made Ricardo, US-made Cummins, and German Deutz brands, as well as different configurations tailored to customer requirements.

Mažas skelbimas

Sieradz

Sieradz

523 km

Generatorius

Proton12000 400

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Funkcionalumas: visiškai funkcionalus, bendras svoris: 260 kg, kuro tipas: dyzelinas, bakelio talpa: 34 l, spalva: juodas, išėjimo srovė: 21 A, išėjimo įtampa: 400 V, išėjimo dažnis: 50 Hz, nominali galia: 12 kW (16,32 AG), nuolatinė galia: 10 kW (13,60 AG), bendras ilgis: 930 mm, bendras plotis: 660 mm, bendras aukštis: 900 mm, sukimosi greitis (maks.): 3 000 aps./min, aušinimo tipas: vanduo, Three-phase diesel generator set with a rated power output of 10kW, equipped with a water-cooled diesel engine. The Proton 12000 400V is first and foremost a high-capacity power source for homes and small businesses, ideal for construction sites, workshops, and agricultural applications.

SUMMARY:

Generator type: Three-phase

Fuel type: Diesel

Iodpfx Afstq Hgye Istb

Water-cooled: Yes

Voltage: 400V

Rated power: 400V – 10,000 Watts (12.5 kVA)

Maximum power (up to 15 minutes): 12,000 Watts (15 kVA)

WEIGHT:

Gross weight: 260 kg

FUEL CONSUMPTION:

2.2 litres per hour (at 70% load)

1.8 litres per hour (at 40% load)

TECHNICAL DATA:

Ready for operation: Yes

Type: Portable

Year of manufacture: 2024

Condition: Brand new

Manufacturer: Proton

Warranty: 24 months

Efficiency cos Φ: 0.8

ENGINE:

Engine model: Proton 2V8-W

Fuel type: Diesel

Engine type: 4-stroke diesel

Number of cylinders: 2

Direct injection: Yes

Cooling type: Water-cooled (radiator equipped)

Displacement: 998 cc

Engine speed: 3,000 RPM

Permitted max. operation time (per cycle): 24 hours

Cooldown time (after one cycle): 60 minutes

Oil pressure sensor: Yes

Oil level sensor: Yes

Timing mechanism: Gear-driven valve train

Engine speed governor: Mechanical

Lubrication method: Forced, with oil pump

Starter: 1,100 W

Oil sump capacity: 2.5 L

Recommended oil: TITAN CARGO MC 10W40 (semi-synthetic for diesel)

Valve type: Electromagnetic, single solenoid controlled

ALTERNATOR:

Alternator model: Proton 220-CAVR-400

Rated current (400V): 21.5 A

Voltage: 400V

Frequency: 50 Hz

Alternator construction: Synchronous

Protection class (alternator): IP 23

ENCLOSURE:

Housing type: Open frame (not enclosed)

Exhaust gas outlet option: Yes

Sound pressure level (LPA): 85 dB (measured at 5 m, open area)

Fuel tank capacity: 34 litres

Average runtime per tank: 12 hours

SOCKETS:

Number of three-phase sockets: 1 unit (32A, 5-pin)

Number of single-phase sockets: 1 unit (32A)

Other sockets: none

DIMENSIONS:

Wheel diameter: 10 cm

Width: 66 cm

Length: 93 cm

Height: 90 cm

FEATURES:

DualPower™ technology: No

ATS compatible: Yes

Voltage stabilizer (AVR): Yes (built-in)

Remote control: No

Starter type: Electric

Glow plugs: Yes

Fuel level indicator: Yes

Voltmeter: Yes

Ammeter: Yes

Current protection: 3xC20 (for 400V)

Hour meter: Yes

Battery: 45 Ah

Transport kit:

Yes – Small wheels

Yes – Handles on both sides

Yes – Swivel castors

Yes – Lockable wheels

COMPREHENSIVE EQUIPMENT

Included in the set:

• Battery

• Air filter

• Oil filter

• Fuel filter

• Service tools

• Plugs

Why choose our company?

We are a company specialising exclusively in generator sets, with over 17 years of experience, constantly striving for the highest quality and reliability in our products. Our range includes generators from 6 to 300kW, powered by various engines including English Ricardo, American Cummins, or German Deutz, and available in a wide array of configurations tailored to customer requirements.

Mažas skelbimas

Baughurst

Baughurst

1 711 km

Skaitmeninės spaudos mašina

CanonOce VarioPrint 6330

Skambinti

Sąlyga: naudotas, Gamybos metai: 2018, Funkcionalumas: visiškai funkcionalus, PARDUODAMA:

Canon Océ VarioPrint 6330 TP Titan – didelio našumo vienaspalvė gamybinė spaudos mašina

Padidinkite spaudos gamybos apimtis ir efektyvumą

Siūloma pilnai veikianti, didelio greičio Canon Océ VarioPrint 6330 TP Titan skaitmeninė gamybinė spausdinimo mašina. Šis įrenginys komercinėje spaudos pramonėje vertinamas dėl itin didelio našumo, ofsetinei artimos kokybės bei plataus žiniasklaidos naudojimo spektro.

Puikiai tinka didelio tiražo gamybos aplinkoms, komercinėms spaustuvėms ar vidinėms organizacijų spaudos tarnyboms, kurios specializuojasi knygų, vadovėlių, transakcinių dokumentų ir tiesioginės reklaminės korespondencijos gamyboje.

Pagrindinės savybės ir privalumai:

Itin didelis greitis: Spaudžia iki 328 A4 formatų per minutę, naudodama Océ Gemini Instant Duplex technologiją, leidžiančią vienu praleidimu atspausdinti abi lapo puses vienu metu.

Aukšta spaudos kokybė: 600 x 1200 dpi rezoliucija, pažangi Océ Copy Press technologija užtikrina matinį paviršių ir tikslų užlaikymą.

Platus laikmenų pasirinkimas: Gali spausdinti ant popieriaus nuo 50 gsm iki 300 gsm (iki 350 gsm patvirtintiems ruošiniams): įskaitant specialius ir tekstūruotus popierius, atskyrimo žymeklius, savikopijuojančias formas.

Tvirta popieriaus tiekimo sistema: Didelės talpos, išplečiama iki kelių padėklų, popieriaus įkrovos talpa iki 24 000 lapų.

Ekologiška: Mažos energijos sąnaudos, minimalios ozono emisijos, mažas šilumos išskyrimas – ekonomiška ir operatoriams draugiška spausdinimo salėms.

Integracija į darbų srautą: Valdoma PRISMAsync valdikliu, palaiko DFD sąsają jungimui su trečiųjų šalių apdailos įranga (įrišimas, segimas, skylučių darymas).

Techniniai duomenys:

Modelis: Canon Océ VarioPrint 6330 TP Titan

Būklė: Paruošta darbui (naudota), pilnai funkcionali

Metai: 2018

Rezoliucija: 600 x 1200 dpi (iki 180 lpi)

Maks. mėnesio našumas: Iki 10 000 000 A4 atvaizdų

Maks. lapo dydis: Iki 350 mm x 500 mm (13,8" x 19,7")

Komplektacija apima: (Peržiūrėkite nuotraukas dėl tikslaus sąrašo)

• Popieriaus padavimo moduliai, 8 x dvigubos popieriaus kasetės

• 2 x didelės talpos priėmimo dėžės

• Palaikomos PCL, IPDS, PostScript kalbos

• PRISMAsync valdiklis

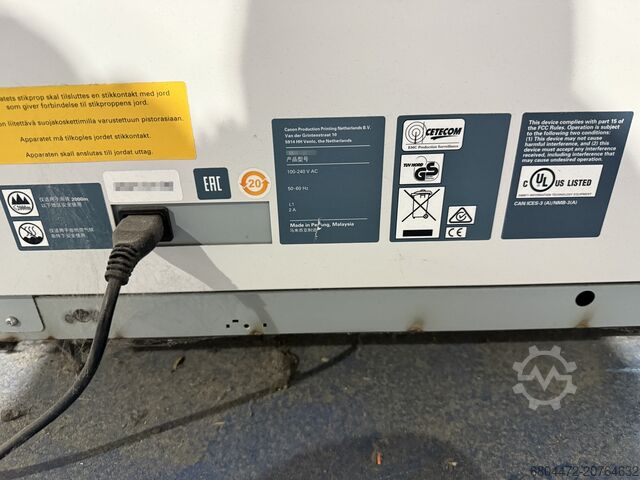

Skaitiklio parodymai:

Matyti nuotraukoje.

Kaina:

(Derintina)

Šios komplektacijos naujo įrenginio kaina viršijo 140 000 €!

Logistika:

Ijdpfxex Hz T Eo Af Ietb

Pirkėjas atsakingas už transportavimą. Įrenginys yra [JK].

Mažas skelbimas

Friedberg

Friedberg

1 149 km

Kiti

ArjesTitan 900 / Shredder

Skambinti

Sąlyga: naudotas, Gamybos metai: 2021, veikimo valandos: 2 338 h, * Arjes Titan 900 smulkintuvas

* Metai: 12-2021

* Eksploatacijos valandos: 2 338 h

* Volvo variklis 565 kW

* Nuotolinio valdymo pultas

* Svoris apie 35 000 kg

Itedjxri Thopfx Af Isb

* Daugiau nuotraukų ir vaizdo įrašų per Whatsapp

* Informacija pateikiama be garantijos, galimas tarpinis pardavimas.

Mažas skelbimas

Valea Mare-Podgoria

Valea Mare-Podgoria

1 149 km

Išpjaustymo presas

ErbaTitan 4

Skambinti

Sąlyga: labai geros būklės (naudotas), Gamybos metai: 2001, Erba Titan 4 with Zenari automatic feeder and stacking system

Year: 2001

Maximum format: 100 x 140 cm

Pneumatic clutch

Maximum speed: 1200 sheets/hour

Isdpfx Afsu Dph Do Ijtb

Automatic feeder and unloader Zenari (2002)

Stacking system

Currently in production

Available immediately.

Mažas skelbimas

Hjørring

Hjørring

892 km

Aušintuvas

Aqua Medic

Skambinti

Sąlyga: geras (naudotas), Gamybos metai: 2017, Funkcionalumas: visiškai funkcionalus, Parduodame 2 vnt. Aqua Medic Titan Professional Flow Cooler 6000, geros būklės. Aqua Medic Titan Professional serijos srautiniai aušintuvai sukurti labai dideliems ir pramoniniams akvariumams, užtikrina aukštą jūrų vandens cirkuliacinio aušinimo efektyvumą. Šie šilumokaičiai pagaminti iš aukštos kokybės titano, jie atsparūs jūros vandeniui, korozijai ir neteršia aplinkos, tad yra itin patikimi. Taip pat titaniniai srautiniai aušintuvai pasižymi dideliu našumu ir yra lengvai valdomi naudojant temperatūros valdiklį. Kaina už vienetą – 2500 €.

Ijdjxykp Topfx Af Istb

Mažas skelbimas

Rzeszów

Rzeszów

581 km

Skaitmeninės spaudos mašina

TICAB PRINTPrinting System for packaging \ CMYK \

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, TITAN DOUBLE

Firma Trade Industrial Company AB to polski producent nowoczesnego sprzętu profesjonalnego, któremu zaufało już ponad 55 krajów na całym świecie. Przemysłowa drukarka TITAN DOUBLE została zaprojektowana do bezkontaktowego, wielkoformatowego druku atramentowego w pełnym kolorze (CMYK).

NASZE ZALETY = TWOJE KORZYŚCI:

TITAN DOUBLE

Nowa maszyna drukująca TICAB PRINT posiada dwie głowice drukujące, co pozwala na jednoczesny druk na dużych elementach w jednym przebiegu. Korzyści dla użytkownika:

• Usprawniony przebieg pracy.

• Szeroki zakres możliwych do zadrukowania próbek.

• Zwiększony komfort pracy.

Jesteśmy oficjalnym partnerem firmy Hewlett Packard. Drukarki TITAN DOUBLE dostępne są w cenie producenta. Zapewniamy szkolenia online oraz pełne wsparcie techniczne.

KLUCZOWE CECHY TITAN DOUBLE:

1) Średnia prędkość drukowania: 50 sztuk na minutę.

2) Możliwość druku już od 1 egzemplarza bez wzrostu kosztu jednostkowego.

3) Brak konieczności przygotowywania matryc czy klisz.

4) Bardzo niski koszt kopii – od 0,01 euro/szt. (dokładny koszt widoczny na monitorze podczas druku).

5) Możliwość druku na różnych materiałach: papier, karton (opakowania złożone i rozłożone), tekstylia, drewno oraz sklejka.

6) Oryginalne oprogramowanie TICAB PRINT (wliczone w cenę drukarki).

7) Autorskie komponenty i akcesoria produkcji własnej.

TITAN DOUBLE to innowacyjny system drukarski umożliwiający podawanie dużych przedmiotów pod głowicę drukującą. Głowice drukujące regulowane są do 10 cm nad taśmą transportera. Wysokiej jakości tusz pigmentowy HP Hewlett Packard zapewnia odporność na blaknięcie, zarysowania oraz działanie wody po wyschnięciu obrazu.

Parametry techniczne głowicy drukującej:

• Szerokość obszaru druku: do 59,4 cm (23,4 cala)

• Długość obszaru druku: od 2,54 cm (1 cal) do 91,44 cm (36 cali)

• Prędkość przesuwu detalu: do 45,72 cm (18 cali) na sekundę

• Prędkość druku: do 50 ark./min A4, do 16 ark./min A3

• Rozdzielczość druku: 1200x1200 dpi

• Kolory: CMYK (cyjan, magenta, żółty, czarny)

• Rodzaj tuszu: pigmentowy wodny

Itsdjvt Uvzepfx Af Ijb

• Połączenie informatyczne: port sieciowy Ethernet 10/100/1000 Base-T

• System operacyjny: Windows (zalecany Windows 10)

• Sterownik Hewlett Packard HP

Oprogramowanie TICAB:

• Monitorowanie bieżącego statusu drukarki.

• Zliczanie ilości wydruków (całkowitej i w bieżącym zadaniu).

• Obliczanie zużycia tuszu.

• Monitorowanie bieżącego poziomu tuszu w kartridżach.

• Uruchamianie funkcji serwisowych i czyszczenia dysz drukarki.

• Rozpoczynanie procedur wymiany mechanizmu czyszczącego.

• Kalibracja dysz drukujących w zakresie liniowości i jednolitości kolorów.

• Uruchamianie trybu szybkiego druku dużej ilości kopii.

Mažas skelbimas

Dąbrowa Górnicza

Dąbrowa Górnicza

619 km

Stacionari asfalto mišinio gamykla

Titan3400

Skambinti

Gamybos metai: 1998, veikimo valandos: 12 500 h, Sąlyga: naudotas, Funkcionalumas: visiškai funkcionalus, Stacjonarna wytwórnia mas bitumicznych Titan 3400 na sprzedaż

Rok produkcji: 1998

Lokalizacja: Polska, woj. śląskie

Łączna produkcja od montażu w Polsce: ok. 3 000 000 ton

Wydajność: 240 t/h

Stan techniczny: dostateczny (maszyna sprawna)

Koszty demontażu i transportu leżą po stronie kupującego. Maszyna będzie gotowa do demontażu na początku 2026 roku.

Na terenie sprzedającego nie przewiduje się możliwości składowania elementów instalacji.

W przypadku zainteresowania ofertą prosimy o przesłanie propozycji ceny oraz wskazanie możliwego terminu odbioru maszyny w zapytaniu.

Oczekujemy szybkiej decyzji.

Specyfikacja:

- Podajniki kruszywa na zimno: 9 zasobników, każdy o pojemności 12 m³

- Bęben suszący: długość 11 m, średnica 2,8 m

- Palnik: Ammann 20 MW; rodzaje paliwa: węgiel brunatny, gaz ziemny, olej opałowy lekki (zbiornik na węgiel brunatny nie wchodzi w skład oferty)

- Filtr workowy: typ z odwrotnym przepływem powietrza, wydajność ok. 120 000 Nm³/h

- Zasobniki na gorące kruszywo: 6 + obejście, wszystkie wyposażone w czujniki poziomu, łączna pojemność >100 ton

Itedpfxjxl Timo Af Ijb

- Mieszalnik: wydajność 4,25 t, napęd 2 x 45 kW

- Zbiorniki bitumu: 4 szt., łączna pojemność 200 ton, system ogrzewania olejem termicznym

- System magazynowania gotowej mieszanki na zewnątrz: wywrotnica i tor wywrotnicy, 4 zasobniki o łącznej pojemności 480 ton, każda komora na wagach

- Dozownik wypełniacza: 3 silosy o łącznej pojemności 120 ton

- Recykling: system dozowania na zimno zutylizowanego asfaltu (RAP)

- Podajnik RAP: 12 m³, taśma wagowa

- Dodatki: systemy dozowania środka adhezyjnego oraz celulozy (silos celulozowy nie wchodzi w skład oferty)

- Poziomy zbiornik oleju opałowego lekkiego o pojemności 50 000 litrów

Sterowanie komputerowe: system Miprotek M4000

Sieć przemysłowa oparta na modułach Phoenix Contact

Mažas skelbimas

București

București

1 204 km

Vertikalios tekinimo staklės

TITANSC33CNC

Skambinti

Sąlyga: geras (naudotas), Vertikali tekinimo staklės SC33 CNC

Gamintojas: TITAN (Rumunija)

Pagaminimo metai: 1986

Pilna staklių kapitalinė renovacija: 2005 m.

Ijdpfsw Eplasx Af Istb

Pagrindiniai techniniai duomenys:

CNC Siemens 802D

Plokštės skersmuo: 3000 mm

Didžiausias tekinimo skersmuo: 3300 mm

Didžiausias darbinis aukštis: 3000 mm

Didžiausias ruošinio svoris: 18000 kg

Stalo sukimosi greitis: 1,02–92 aps./min

Darbinė padavimo eiga: 0,05–5 mm/aps.

Pagrindinio variklio galia: 55 kW

Bendri matmenys: 5600 x 5300 x 5400 mm

Svoris: 47350 kg

Staklės prijungtos prie elektros.

Mažas skelbimas

Halberstadt

Halberstadt

923 km

Cilindrinė šlifavimo mašina

TITANRU 350 x 1-1500

Skambinti

Sąlyga: geras (naudotas), Gamybos metai: 1990, Ref. No.: 10301

Manufacturer: TITAN

Model: RU 350 x 1-1500

Year of Manufacture: 1990

Control Type: Conventional

Location: Halberstadt

Country of Origin: USA

Max. Grinding Length: 1,500 mm

Itjdpexmd Rwefx Af Ieb

Max. Workpiece Weight: 300 kg

Grinding Diameter: 350 mm

Max. Grinding Wheel Diameter: 280-500 mm

Grinding Wheel Width: 80-100 mm

Mažas skelbimas

Wysoka

Wysoka

495 km

Pramoninis robotas

HANWHAHCR-12

Skambinti

Sąlyga: naujas, Gamybos metai: 2024, Sprzedajemy kompletną, zrobotyzowaną stację spawalniczą, idealną do profesjonalnych zastosowań spawalniczych. Zestaw obejmuje nowoczesnego robota współpracującego HCR-12A, zaawansowane źródło prądu spawalniczego EWM, wysokiej jakości stół spawalniczy Siegmund z akcesoriami, a także system odciągu dymów spawalniczych Kemper oraz osłonę ochronną.

1. Robot współpracujący HCR-12A

Robot HCR-12A to zaawansowane ramię robotyczne o wysokiej powtarzalności i bezpiecznej pracy.

Udźwig: 12 kg

Zasięg: 1300 mm

Liczba osi: 6

Prędkość narzędzia: 1 m/s (maks. 1.2 m/s)

Masa: 51 kg

Powtarzalność: 0,07 mm

Klasa ochrony: IP54

Temperatura pracy: 0-50°C

Szacowany czas pracy: 35 000 h

Typ złącza EOAT: ISO9409-1-50-4-M6

Wejścia cyfrowe: 4

Wyjścia cyfrowe: 4

Wejścia analogowe: 2

Certyfikaty: EN ISO 13849-1, Kat. 3, PLd, EN ISO 10218-1, CE MD, KCS

Zakresy osi: J1: ±180°, J2: ±150°, J3: ±165°, J4: ±190°, J5: ±170°, J6: ±360°

2. Źródło prądu spawalniczego EWM Titan XQ 350 puls DW EX

Wysokiej klasy spawarka EWM ze zintegrowanym podwoziem i podajnikiem drutu, umożliwiająca szeroki zakres procesów spawalniczych.

Model: Titan XQ 350 puls DW EX

Procesy spawania: obejmuje wszystkie charakterystyki i procesy spawalnicze. Dostępne procesy:

rootArc/rootArc puls – do spawania warstwy graniowej

coldArc/coldArc XQ – spawanie z maksymalnie zredukowanym wpływem ciepła, idealne do cienkich blach

forceArc/forceArc puls – do szybkiego spawania z głębokim przetopem

wiredArc puls XQ – stała głębokość przetopu niezależnie od zmiennej długości wysięgu drutu

Positionweld dla wszystkich materiałów – proces ułatwiający spawanie pozycyjne

Standard, Puls, superPuls, TIG, MMA, żłobienia (Gouging)

Wyposażenie:

Zintegrowane podwozie

Zintegrowany podajnik drutu

Cyfrowa kontrola gazu osłonowego

Uchwyt spawalniczy RMT 551 W 22.5° 3m

Przewód masowy 70mm² 2m

Wąż gazowy 3m

Przewód zasilający 5m z wtyczką 32A 5P

Zestaw rolek V 1.0-1.2mm

Adapter na szpulę K300

Reduktor ARG/CO2

Itsdpfx Afjwm Hlys Ieb

3. Stół spawalniczy SIEGMUND 1500x3000 mm

Profesjonalny stół spawalniczy zapewniający stabilne i precyzyjne środowisko pracy.

Model: Siegmund Professional Extreme 8.7 z azotowaniem plazmowym – System 16

Akcesoria stołowe SIEGMUND

4. KEMPER VacuFil compact – odciąg dymów spawalniczych

Kompaktowy i wydajny system odciągu dymów spawalniczych.

Model: KEMPER VacuFil compact

Cechy:

Płynna preselekcja siły zasysania dla różnych palników odciągowych

Intuicyjna obsługa jednym przyciskiem (również w rękawicach)

Wysoka wydajność ssania dzięki sprężarce bocznokanałowej

Kompaktowa konstrukcja, odpowiednia do zmiennych miejsc pracy

Automatyczne oczyszczanie filtra (inicjowane manualnie)

Sprężarka bocznokanałowa

Gniazdo ładowania USC Type-A

Monitoring siły ssania

5. KEMPER 3-częściowy ekran ochronny z lamelami

Zapewnia ochronę przed promieniowaniem i odpryskami spawalniczymi.

Typ: 3-częściowy ekran ochronny z lamelami

Zalety: Wytrzymała jakość przemysłowa dzięki stabilnej konstrukcji, możliwość elastycznego zastosowania dzięki zestawowi kółek

Mažas skelbimas

Siegen

Siegen

1 160 km

Plazminio pjovimo staklės

Eckert Cutting Technology GmbHTitan DrillCut

Skambinti

Sąlyga: naujas, Titan DrillCut – lanksti pjovimo ir gręžimo centras aukščiausiam efektyvumui

Isdefz A I Ejpfx Af Ietb

Titan DrillCut yra našus CNC apdirbimo centras, kuris vienoje mašinoje apjungia termišką pjovimą (plazma arba autogeniniu būdu) su tiksliu gręžimu ir sriegimu. Tvirta portalinė konstrukcija užtikrina vibracijų netrikdomą apdirbimą net ir dirbant su storomis iki 200 mm medžiagomis.

Integruota VarioDrill sistema leidžia efektyviai ir be kietėjimo apdirbti skyles nuo Ø 6 iki 40 mm bei sriegius nuo M4 iki M20. Automatinė įrankių keitimo sistema užtikrina greitą perėjimą tarp gręžimo, išleidimo ir sriegimo – idealiai tinka automatizuotoms gamybos linijoms.

Ši mašina yra puikus sprendimas metalinių konstrukcijų gamybai, mašinų gamybai ir pramoninei metalo apdirbimui, kai itin svarbios aukščiausia precizika, lankstumas ir gamybos greitis.

Mažas skelbimas

Mudersbach

Mudersbach

1 167 km

Centro tekinimo staklės

BernardoTitan 660 x 3000

Skambinti

Sąlyga: naujas, Bernardo Universal Lathe Titan 660 x 3000

Technical Specifications

Centre Distance: 3000 mm

Centre Height: 330 mm

Swing Diameter over Bed: 660 mm

Swing Diameter over Gap: 900 mm

Swing Diameter over Cross Slide: 460 mm

Bed Width: 400 mm

Spindle Bore: 105 mm

Spindle Mount: DIN 55029, D1-8

Speed Range: (16) 25 - 1600 rpm

Longitudinal Feed Range: (25) 0.044 - 1.48 mm/rev

Cross Feed Range: (25) 0.022 - 0.740 mm/rev

Metric Threads: (54) 0.45 - 120 mm

Inch Threads: (54) 7/16 - 80 TPI

Quill Diameter: 90 mm

Quill Travel: 235 mm

Quill Taper: MT 5

Motor Power: 7.5 kW (10.0 HP)

Machine Dimensions (W x D x H): 4630 x 1200 x 1520 mm

Weight approx.: 3300 kg

Features

• Versatile applications in general engineering, production, single-part manufacturing, ...

• Central, ergonomic controls for feeds and threading, with leadscrew and feed rod

• Prism-shaped bed made of cast iron, inductively hardened and precision ground

• Modern main spindle bearing with precision angular contact roller bearings

• Hardened and ground gears and shafts, including in the feed gearbox

• Standard with rapid traverse in both longitudinal and cross axes to reduce secondary times

• Large spindle bore (105 mm) for workpieces with large diameters

• Smooth start-up via mechanical multi-plate clutch

• Electromechanical foot brake to reduce secondary times

• Maximum cutting performance, even during facing operations

• The bed is heavily ribbed to stiffen the guideways and minimise vibration effects

Scope of Delivery

• 3-axis digital readout ES-12 V with LCD display

• Slip clutch

• Rapid traverse on longitudinal and cross axes

• LED machine lamp

• 3-jaw steel chuck PO3-315 mm / D8

• Face plate 450 mm

• Fixed steady rest – max. passage dia. 180 mm

Itsdpfx Afjxxayfe Ijb

• Travelling steady rest – max. passage dia. 120 mm

• 2 live centres

• Motor with magnetic brake according to CE standard

• Foot pedal with brake function according to CE

• Initial fill with Shell Tellus 46

• Coolant system

• Quick-change tool post with 4 inserts

• Safety guard for quick-change tool post

• Change gears

• Reducing sleeve

• Chip guard at rear

• Cable management via energy chain

• Operating tools

Mažas skelbimas

Mudersbach

Mudersbach

1 167 km

Centro tekinimo staklės

BernardoTitan 560 x 3000 Pro Vario

Skambinti

Sąlyga: naujas, Bernardo Universal Lathe Titan 560 x 3000 Pro Vario

Technical Specifications

Distance between centers: 3000 mm

Center height: 280 mm

Swing over bed: 560 mm

Swing over gap: 785 mm

Swing over cross slide: 350 mm

Bed width: 350 mm

Spindle bore: 105 mm

Spindle mount: DIN 55029, D1–8

Speed range: 25–220 / 220–1500 rpm

Itjdpfsxl Tdqox Af Isb

Longitudinal feed range (42): 0.055–3.061 mm/rev

Cross feed range (42): 0.025–1.384 mm/rev

Metric threads (41): 0.1–14 mm

Inch threads (60): 2–112 TPI

Tailstock quill diameter: 75 mm

Quill stroke: 185 mm

Quill taper: MT 5

Motor power: 7.5 kW (10.0 HP)

Machine dimensions (L): 4340 mm

Width x Height: 1150 x 1610 mm

Weight approx.: 3000 kg

Features

• Standard with Delta frequency inverter for high torque at low speeds and nearly constant speed under load

• Infinitely variable speed control, speed is displayed digitally

• Versatile applications in general mechanical engineering, production, single-part manufacturing, etc.

• Removable gap bridge enables machining of large-diameter workpieces

• Standard with rapid traverse in longitudinal and cross directions for reduced non-productive time

• Modern main spindle bearings with precision angular contact ball bearings

• The one-piece machine bed is extremely torsion-resistant and low in vibration, providing essential conditions for accurate turning

• Tailstock can be offset for taper turning

• Centralized lubrication for the carriage

Scope of delivery

• 3-axis digital readout ES-12 V with LCD display

• 3-jaw chuck PS3-315 mm / D8

• Fixed steady rest – max. capacity 180 mm

• Travelling steady rest – max. capacity 120 mm

• Foot pedal with brake function (CE compliant)

• Guard for quick-change tool post

• LED machine lamp

• Initial fill with Shell Tellus 46

• Face plate 450 mm

• 2 live centers

• Frequency inverter

• Digital speed display

• Slip clutch

• Rapid traverse in longitudinal and cross directions

• Coolant system

• Quick-change tool post with 4 holders

• Change gears

• Reducing sleeve

• Chip guard

• Operator tools

Mažas skelbimas

Mudersbach

Mudersbach

1 167 km

Centro tekinimo staklės

BernardoTitan 560 x 2000 Pro Vario

Skambinti

Sąlyga: naujas, Bernardo Universal Lathe Titan 560 x 2000 Pro Vario

Technical Specifications

Distance between centers: 2,000 mm

Center height: 280 mm

Swing over bed: 560 mm

Swing over gap: 785 mm

Swing over cross slide: 350 mm

Bed width: 350 mm

Spindle bore: 105 mm

Spindle mount: DIN 55029, D1 – 8

Speed range: 25 – 220 / 220 – 1500 rpm

Longitudinal feed range (42): 0.055 – 3.061 mm/rev

Cross feed range (42): 0.025 – 1.384 mm/rev

Metric threads (41): 0.1 – 14 mm

Inch threads (60): 2 – 112 TPI

Quill diameter: 75 mm

Quill travel: 185 mm

Quill taper: MT 5

Motor power: 7.5 kW (10.0 HP)

Machine dimensions Length: 3,340 mm

Width x Height: 1,150 x 1,610 mm

Weight approx.: 2,720 kg

Features

• Equipped as standard with Delta frequency converter for high torque at low speeds and nearly constant speed under load

• Infinitely variable speed control, set speed is read on a digital display

• Versatile applications in general engineering, production, single-part manufacturing, etc.

• Removable gap bridge enables machining of large-diameter workpieces

• Standard rapid traverse longitudinal and cross to reduce non-productive times

• Modern main spindle bearing with precision angular contact ball bearings

• The one-piece cast bed is extremely torsion-resistant and vibration-damping, ensuring precise turning

• Tailstock can be offset for taper turning

• Centralized lubrication for the carriage

Scope of Delivery

• 3-axis digital readout ES-12 V with LCD display

• 3-jaw chuck PS3-315 mm / D8

• Fixed steady rest – max. capacity 180 mm diameter

Itedpfoxl Tc Tox Af Ieb

• Follow rest – max. capacity 120 mm diameter

• Foot pedal with brake function according to CE

• Safety device for quick-change toolpost

• LED machine lamp

• Initial fill with Shell Tellus 46

• Face plate 450 mm

• 2 live centers

• Frequency inverter

• Digital speed display

• Overload clutch

• Rapid traverse longitudinal and cross

• Coolant system

• Quick-change toolpost with 4 holders

• Change gears

• Reducing sleeve

• Chip guard

• Operating tools

Patikimumo ženklas

Machineseeker sertifikuoti platintojai

Mažas skelbimas

Mudersbach

Mudersbach

1 167 km

Centro tekinimo staklės

BernardoTitan 560 x 1500 Pro Vario

Skambinti

Sąlyga: naujas, Bernardo Universal Lathe Titan 560 x 1500 Pro Vario

Technical Specifications

Distance between centers: 1500 mm

Center height: 280 mm

Swing over bed: 560 mm

Swing over gap: 785 mm

Swing over cross slide: 350 mm

Bed width: 350 mm

Spindle bore: 105 mm

Spindle mount: DIN 55029, D1 – 8

Speed range: 25 – 220 / 220 – 1500 rpm

Longitudinal feed range (42): 0.055 – 3.061 mm/rev

Cross feed range (42): 0.025 – 1.384 mm/rev

Metric threads (41): 0.1 – 14 mm

Inch threads (60): 2 – 112 TPI

Quill diameter: 75 mm

Quill travel: 185 mm

Quill taper: MT 5

Motor power: 7.5 kW (10.0 HP)

Machine dimensions (L): 2840 mm

Width x height: 1150 x 1610 mm

Weight approx.: 2420 kg

Features

• Standard with Delta frequency inverter for high torque at low speeds and nearly constant speed under load

• Stepless speed control, speed is displayed digitally

• Versatile range of applications in general machine building, production, single-part manufacturing, etc.

• Removable gap bridge allows machining of large-diameter workpieces

• Standard with rapid traverse in both longitudinal and cross axes to reduce non-productive times

• Modern precision angular contact ball bearing headstock spindle

• One-piece cast machine bed, highly torsion-resistant and low-vibration, providing essential prerequisites for precision turning

• Tailstock can be offset for taper turning

• Central lubrication for the carriage

Scope of Delivery

• 3-axis digital readout ES-12 V with LCD display

• 3-jaw chuck PS3-315 mm / D8

• Fixed steady rest – max. bore ø 180 mm

• Travelling steady rest – max. bore ø 120 mm

• Foot pedal with CE-compliant brake function

• Safety guard for quick-change tool post

• LED machine lamp

• First fill with Shell Tellus 46

• Faceplate 450 mm

• 2 centers

• Frequency inverter

• Digital speed display

• Overload clutch

• Rapid traverse longitudinal and cross

• Coolant system

• Quick-change tool post with 4 holders

Itjdpjxl Tcyefx Af Iob

• Change gears

• Reducing sleeve

• Chip guard

• Service tools

Mažas skelbimas

Krefeld

Krefeld

1 228 km

Perforavimo tiglis

Erba Titan5-EM

Skambinti

Sąlyga: paruoštas naudoti (naudotas), Gamybos metai: 1977, Funkcionalumas: visiškai funkcionalus, ERBA TITAN

Itsdpfjxn T Hwox Af Isb

100 x 160 cm

metai 1977, kapitaliai suremontuota 2007

su visais standartiniais priedais

Mažas skelbimas

Dnipro

Dnipro

1 069 km

Stovinčios siūlės stogo skardos formuotojas

LLC EvolutionerF3 standing seam roof machine

Skambinti

Sąlyga: naujas, Gamybos metai: 2025, Die Doppelstehfalz-Profiliermaschine F3 dient zur Herstellung von Doppelstehfalz-Verbindungen für Dachpaneele, die zur Montage von Doppelstehfalzdächern verwendet werden.

Das Doppelstehfalzdach ist weit verbreitet, weil durch die spezielle Form des Falzes an den Kontaktstellen der Paneele kein Wasser unter die geschlossenen Doppelstehfalz-Paneele eindringen kann. Diese spezielle Konstruktion bewirkt, dass sich die Doppelstehfalz-Paneele an den Verbindungsstellen überlappen. Nach der Montage auf dem Dach wird die Falzverbindung mit speziellen Doppelstehfalzschließwerkzeugen verschlossen (manuelles Werkzeug zum Verschließen des Doppelstehfalzfalzes und elektrische Maschine zum Verschließen des Doppelstehfalzfalzes).

Ein wesentlicher Vorteil dieser Stehfalzmaschine ist die unkomplizierte Einstellung der Paneelbreite. An einer Seite der Stehfalzmaschine befindet sich eine spezielle Schraube, mit deren Verstellung der Bediener die Paneelbreite einfach anpassen kann.

Das Einstellen der Stehfalz-Profiliermaschine nimmt daher wenig Zeit in Anspruch und erhöht die Effizienz des Bedieners.

Mit dieser Maschine lassen sich Doppelstehfalz-Paneele aus unterschiedlichen Metallen herstellen (verzinkter Stahl, stahlbeschichtetes Kupfer, Zink, Titan usw.).

Die Stehfalz-Profiliermaschine verfügt über sechs Walzenpaare, die die charakteristische Form der Doppelstehfalz-Paneele formen.

Die Maschine kann sowohl für 220V- als auch für 380V-Stromanschluss gefertigt werden.

Isdpfxshz Twwe Af Iotb

Optional erhältlich für die Stehfalzmaschine:

- Zusätzliches Walzenpaar für das Einprägen von Sicken in die Dachpaneele

- Zusätzliches Walzenpaar für das Profilieren von stark gebogenen Paneelen

- Schneidmesser

- Abwickelhaspel

- Manuelles Schloss-Schließwerkzeug

- Elektrische Schloss-Schließmaschine

- Blechschneidemaschine zum Ablängen

Dank ihres geringen Gewichts und kompakter Abmessungen kann unsere Doppelstehfalz-Profiliermaschine direkt am Montageort des Doppelstehfalzdaches eingesetzt werden. Das spart Kosten für zusätzliche Werkstatträume, Lagerung und Transport der Dachpaneele zum Montageort.

Unser Unternehmen produziert diese Doppelstehfalz-Profiliermaschine seit 2005 und verfügt somit über umfangreiche Erfahrung – wir bieten Ihnen eine überzeugende Lösung für Ihr Unternehmen.

Für Preisinformationen und Liefermöglichkeiten der Doppelstehfalz-Profiliermaschine kontaktieren Sie uns bitte. Wir beraten Sie gern ausführlich.

Mažas skelbimas

Vokietija

Vokietija

1 073 km

Veržliarakčio piktogramą didelio sukimo momento hidrauliniai.

TitanLP2

Skambinti

Gamybos metai: 2017, Sąlyga: beveik kaip naujas (parodų įrenginys), mašinos/transporto priemonės numeris: 6151550180, Demonstration tool:

Hydraulic high-torque wrench LP2 by TITAN without screw cassette

Torque range: 363 to 2476 Nm

Drive: suitable for screw cassettes (wrench sizes SW 19 to SW 60)

Screw cassettes are optional and not included in the scope of delivery

Weight: depending on the cassette from 2.56 to 3.16 kg

Overall length with cassette: 226.1 mm

Overall height: 31.8 mm

Advantages:

Itodpfodv Scfjx Af Isb

- Patented Multi-Axis Connection: Freely movable hose, multi-positioning of the hose

- Slim design: Easily fits into all tight spaces

- Unique wide-track locking teeth

- Modular concept

Features:

- Certified accuracy +/-3%

- The Titan WIDE Track ratchet tooth design distributes force evenly, provides a greater contact area, and brings the power to perfectly loosen the fastener—every time

- Handcrafted from the highest-quality aerospace materials for ultimate strength and durability (AQ Grade 7075-T6 aluminum alloy)

- Low profile and slim design for extremely tight spaces

Palengviname jums paiešką: "metalski zavod tito"

Jūs iš karto ir nemokamai gausite naujus pasiūlymus el. paštu.

Galite bet kada paprastai nutraukti paieškos užduotį.

Naudota Metalski Zavod Tito (110)

Dabar ieškokite visame Machineseeker su daugiau nei 200 000 naudotų mašinų.Naršykite populiariausius mašinų pavadinimus:

- Dvigubo Pjovimo

- Dvigubo Pjovimo Staklytės

- Dvigubo Pjovimo Įvertinti

- Kampinis Apvalus Pjovimo

- Lukšto Pjovimo

- Metalo Drožlių

- Metalo Tekinimo Stakles

- Metalo Tekinimo Stakles Priedai

- Mobiliojo Ryšio Plokštės Pjovimo

Sužinokite dabar

+44 20 806 810 84

+44 20 806 810 84

Įdėti skelbimą dabar

*už skelbimą/mėnuo