Cnc Apdirbimo Centrai pirkti naudotą (48 727)

Vokietija

Vokietija CNC vertikalus apdirbimo centras

MatsuuraMAM72-25V

Vokietija

Vokietija CNC medžio apdirbimo centras

Hamuel ReichenbacherVision III-TT-L-5-Achs

Vokietija

Vokietija CNC profilių apdirbimo centras

SchücoAF 300

Vokietija

Vokietija CNC apdirbimo centras

Deckel-MahoDMU 80 T

Vokietija

Vokietija CNC apdirbimo centras

Hüller HilleBluestar 5+

Atraskite daugiau naudotų mašinų

Vokietija

Vokietija CNC vertikalus apdirbimo centras

BridgeportInteract 412

Vokietija

Vokietija CNC apdirbimo centras

RödersRXP 300

Vokietija

Vokietija CNC apdirbimo centras

DMG MoriHSC 55 linear

Vokietija

Vokietija CNC vertikalus apdirbimo centras

SpinnerVC 850

Vokietija

Vokietija CNC vertikalus apdirbimo centras

StamaMC 520

Vokietija

Vokietija CNC apdirbimo centras

Deckel MahoDMC 105 V Linear

Vokietija

Vokietija CNC apdirbimo centras

EnshuWE30Ve

Vokietija

Vokietija CNC lakštinio metalo apdirbimo centras

Salvagini

Vokietija

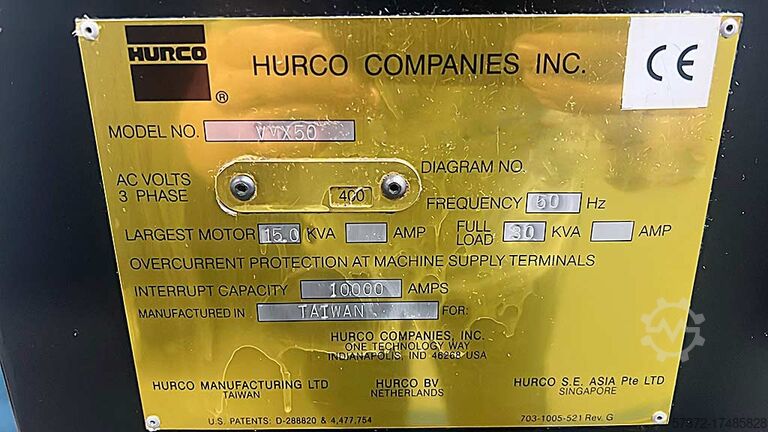

Vokietija CNC apdirbimo centras

HurcoVMX 50

Vokietija

Vokietija CNC profilių apdirbimo centras

MAKAPA 37

Vokietija

Vokietija CNC apdirbimo centras

DMG MoriDMC 835 V

Vokietija

Vokietija CNC vertikalus apdirbimo centras

ChironFZ 22 high-speed

Vokietija

Vokietija CNC judančių kolonų apdirbimo centras

SoraluceFL 6000

Vokietija

Vokietija CNC 5 ašių apdirbimo centras

MazakVaruaxis 630-5X II T

Vokietija

Vokietija CNC vertikalus apdirbimo centras

BrotherTC-225

Vokietija

Vokietija CNC apdirbimo centras

Matec30 HV

Vokietija

Vokietija CNC apdirbimo centras

KitamuraMyCenter HX3000iG

Vokietija

Vokietija CNC vertikalus apdirbimo centras

DMG MoriDMC 650 V

Vokietija

Vokietija CNC apdirbimo centras

DMGDMU 80 T

Vokietija

Vokietija