Betono presasHidralmac

150 Tonnen Betonpresse

Betono presas

Hidralmac

150 Tonnen Betonpresse

Gamybos metai

2017

Sąlyga

Naujas

Vieta

Ennepetal

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

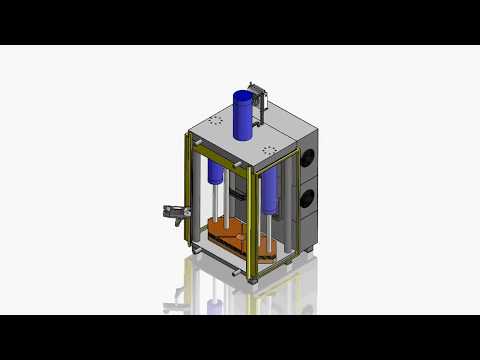

- Įrenginio aprašas:

- Betono presas

- Gamintojas:

- Hidralmac

- Modelis:

- 150 Tonnen Betonpresse

- Serijos Nr.:

- DF0149

- Gamybos metai:

- 2017

- Sąlyga:

- naujas

Kaina ir vieta

- Vieta:

- Scharpenberger Str. 96-98, 58256 Ennepetal, Deutschland

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A3871212

- Nuorodos Nr.:

- 1358-NEBR-1215

- Naujinta paskutinį kartą:

- Data 2025.03.27

Aprašymas

Pressure: 2x 75 / 150 t

Passage width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: Main motor 22 kW

Machine weight approx.: 6.5 t

Space requirement approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Upper ram dimensions approx.: 870 x 350 x 150 mm

Lower ram dimensions approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel distance of both lift cylinders and the pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15–0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via non-contact sensors: 0.5 mm

The press is equipped with two column guides, each with a diameter of 120 mm, guiding both the lower and upper rams. The guides are made of bronze.

The lower ram is robustly designed with a thickness of 150 mm.

The upper ram is also equipped with a 150 mm thick steel plate.

Iodpfx Asd Aftpjf Iotb

The machine’s base plate is made of 72 mm thick steel, ensuring tip-over stability during movement. For this reason, the oil tank with the hydraulic unit is also mounted close to the base.

Both the hydraulic system and the electrical components are directly integrated into the machine and protected from contamination by an enclosure.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also equipped with air cooling.

For any future maintenance work on the hydraulics, the inner rear panel of the press can be easily removed.

The two-hand control is fixedly mounted to facilitate transport; however, it remains articulated and movable.

High-resolution light curtains prevent personnel from entering the danger zone.

For user-friendly operation, the machine features transparent acrylic windows (6 mm thick) on both sides. These may need replacement after several years of use, but the costs involved are minimal.

Additionally, the press is equipped with four powerful LED lights built into the top plate.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Passage width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: Main motor 22 kW

Machine weight approx.: 6.5 t

Space requirement approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Upper ram dimensions approx.: 870 x 350 x 150 mm

Lower ram dimensions approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel distance of both lift cylinders and the pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15–0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via non-contact sensors: 0.5 mm

The press is equipped with two column guides, each with a diameter of 120 mm, guiding both the lower and upper rams. The guides are made of bronze.

The lower ram is robustly designed with a thickness of 150 mm.

The upper ram is also equipped with a 150 mm thick steel plate.

Iodpfx Asd Aftpjf Iotb

The machine’s base plate is made of 72 mm thick steel, ensuring tip-over stability during movement. For this reason, the oil tank with the hydraulic unit is also mounted close to the base.

Both the hydraulic system and the electrical components are directly integrated into the machine and protected from contamination by an enclosure.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also equipped with air cooling.

For any future maintenance work on the hydraulics, the inner rear panel of the press can be easily removed.

The two-hand control is fixedly mounted to facilitate transport; however, it remains articulated and movable.

High-resolution light curtains prevent personnel from entering the danger zone.

For user-friendly operation, the machine features transparent acrylic windows (6 mm thick) on both sides. These may need replacement after several years of use, but the costs involved are minimal.

Additionally, the press is equipped with four powerful LED lights built into the top plate.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2018

Pateikti užklausą

Telefonas & Faksas

+49 209 9... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Hessisch Lichtenau

Hessisch Lichtenau

1 040 km

Apvalus lovio vibracinis apdailos aparatas

WALTHER TROWALCLS-230

WALTHER TROWALCLS-230

Mažas skelbimas

Schorfheide

Schorfheide

715 km

Stacionarus maišymo įrenginys

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Mažas skelbimas

Mindelheim

Mindelheim

1 215 km

Apdirbimo centras

Deckel MahoDMC 60U Hi-dyn

Deckel MahoDMC 60U Hi-dyn

Mažas skelbimas

Italija

Italija

1 694 km

Visiškai suremontuotas karštas radialinis kalimas

CNC GFMSX-13

CNC GFMSX-13

Mažas skelbimas

Hochdorf

Hochdorf

1 220 km

Temperatūros aušinimo įrenginys (TCU) / šaldiklis

SingleChill Plus Testing CHT-130

SingleChill Plus Testing CHT-130

Mažas skelbimas

Oftersheim

Oftersheim

1 222 km

Hidraulinis įrenginys

Parker

Parker

Mažas skelbimas

Ciriè

Ciriè

1 596 km

Dviejų kolonų hidraulinis presas

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Mažas skelbimas

Fuldatal

Fuldatal

1 040 km

Ciklas valdomas tekinimo

Weisser HeinbronnHECKTOR CNC 295x2000

Weisser HeinbronnHECKTOR CNC 295x2000

Mažas skelbimas

Wiefelstede

Wiefelstede

1 046 km

Hidraulinis agregatas 5,5 kW / 1455 U / min

H+LDK52 1-6-250P-391K

H+LDK52 1-6-250P-391K

Mažas skelbimas

Vokietija

Vokietija

999 km

CNC tekinimo ir frezavimo centras

Niles-SimmonsN30/2500 MC

Niles-SimmonsN30/2500 MC

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida