Vertikalus apdirbimo centrasBrema

Vektor 15 - 13

Vertikalus apdirbimo centras

Brema

Vektor 15 - 13

Gamybos metai

2019

Sąlyga

Naudotas

Vieta

Sesto Calende

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Vertikalus apdirbimo centras

- Gamintojas:

- Brema

- Modelis:

- Vektor 15 - 13

- Gamybos metai:

- 2019

- Sąlyga:

- naudotas

Kaina ir vieta

- Vieta:

- Sesto Calende, Italy

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A10298021

- Nuorodos Nr.:

- MHF003

- Naujinta paskutinį kartą:

- Data 2024.10.18

Aprašymas

Highly flexible vertical machining center for milling, drilling, and cutting. The BREMA patent for processing. Due to the vertical alignment, this machine series is by far the most flexible and productive machine on a very high quality level. In addition, the automatic panel return/rotation system ensures fully automatic operation.

It is possible to work on all 6 sides of the panel up to a height of 1300 mm.

Working dimensions:

* Length: 300 - 2500 mm

* Height: 60 - 1300 mm

* Thickness: 10 - 80 mm

* Maximum weight: 50 kg

Machine programming and control system via PC with TPA Albatros software.

The programming editor with a high-level software interface allows for simple and intuitive machine programming, and additionally enables:

* Linear, circular, and helical interpolation

* Double zero point

* Mirror program management

* Turret tool diameter optimizer

* Independent spindle diameter optimizer

* DXF file conversion (geometric conversion)

Ksdpfxjl Ikzgs Af Iodg

* Import of job lists in ASCII format

* Extra key for office-based programming

* Hand-held barcode reader

* 17-inch LCD monitor

* Professional operating system Windows 7

Panel feeding and handling via motorized vertical transfer with rollers and rubber-coated pressure applicators to secure the panel during processing, with a powered mat length of 2000 mm, equipped with electronically adjustable speed regulation via converter. Photoelectric sensors and NC programming ensure that one or several panels can be loaded sequentially via selector switch.

Panel height reading system, consisting of an independent axis capable of reading the panel height before loading into the machine. Reading tolerance of +/- 0.15 mm. If the tolerance is exceeded, a message is displayed to the operator and the machine stops the current operation.

Panel thickness reading system via mechanical probe.

Horizontal vice – M.O. axis: Allows the thickness of the workpiece to be detected by the program.

Vertical vice – M.V. axis: Allows the program to detect the height dimension of the workpiece to be processed.

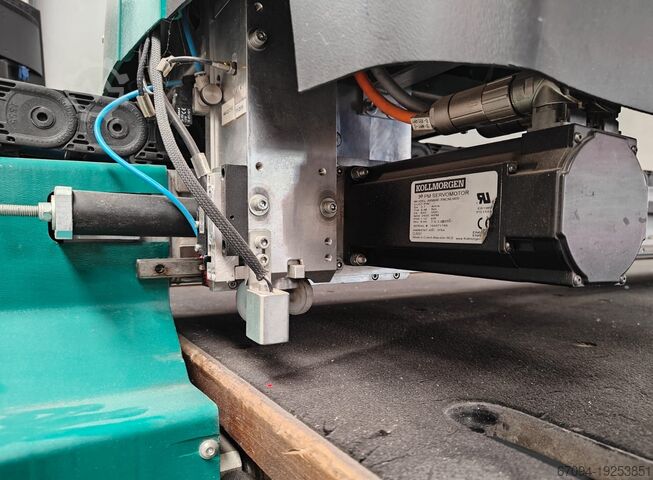

Chain – X-axis – patented double section with laser photoelectric cells that can read the reference zero point before processing starts. The double section enables machining on the underside of the panel, making it possible to machine all six sides of the panel. Brushless motors with programmable speed control via NC.

Drilling unit with independent spindles 7 + 17 x 32 mm:

24 independent spindles with 32 mm pitch, arranged as follows:

* 7 spindles aligned along the X-axis

* 17 spindles aligned along the Y-axis

Driven by a high-frequency motor enabling spindle rotation changes up to 7000 rpm. The brushless motor allows for control of drilling depth and feed rate.

Top turret milling group with 10 positions and NC-controlled tool change. 11 kW motor with direct power transmission to the tool up to 18,000 rpm. Turret rotation is performed by a controlled axis with a brushless motor.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

It is possible to work on all 6 sides of the panel up to a height of 1300 mm.

Working dimensions:

* Length: 300 - 2500 mm

* Height: 60 - 1300 mm

* Thickness: 10 - 80 mm

* Maximum weight: 50 kg

Machine programming and control system via PC with TPA Albatros software.

The programming editor with a high-level software interface allows for simple and intuitive machine programming, and additionally enables:

* Linear, circular, and helical interpolation

* Double zero point

* Mirror program management

* Turret tool diameter optimizer

* Independent spindle diameter optimizer

* DXF file conversion (geometric conversion)

Ksdpfxjl Ikzgs Af Iodg

* Import of job lists in ASCII format

* Extra key for office-based programming

* Hand-held barcode reader

* 17-inch LCD monitor

* Professional operating system Windows 7

Panel feeding and handling via motorized vertical transfer with rollers and rubber-coated pressure applicators to secure the panel during processing, with a powered mat length of 2000 mm, equipped with electronically adjustable speed regulation via converter. Photoelectric sensors and NC programming ensure that one or several panels can be loaded sequentially via selector switch.

Panel height reading system, consisting of an independent axis capable of reading the panel height before loading into the machine. Reading tolerance of +/- 0.15 mm. If the tolerance is exceeded, a message is displayed to the operator and the machine stops the current operation.

Panel thickness reading system via mechanical probe.

Horizontal vice – M.O. axis: Allows the thickness of the workpiece to be detected by the program.

Vertical vice – M.V. axis: Allows the program to detect the height dimension of the workpiece to be processed.

Chain – X-axis – patented double section with laser photoelectric cells that can read the reference zero point before processing starts. The double section enables machining on the underside of the panel, making it possible to machine all six sides of the panel. Brushless motors with programmable speed control via NC.

Drilling unit with independent spindles 7 + 17 x 32 mm:

24 independent spindles with 32 mm pitch, arranged as follows:

* 7 spindles aligned along the X-axis

* 17 spindles aligned along the Y-axis

Driven by a high-frequency motor enabling spindle rotation changes up to 7000 rpm. The brushless motor allows for control of drilling depth and feed rate.

Top turret milling group with 10 positions and NC-controlled tool change. 11 kW motor with direct power transmission to the tool up to 18,000 rpm. Turret rotation is performed by a controlled axis with a brushless motor.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2017

Pateikti užklausą

Telefonas & Faksas

+39 0331 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Lennestadt

Lennestadt

1 151 km

Apdirbimo centras su perėjimo mechanizmu

BRE.MAVEKTOR 15-13 CNC

BRE.MAVEKTOR 15-13 CNC

Mažas skelbimas

Hedel

Hedel

1 288 km

Krano sunkvežimis

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

Mažas skelbimas

Barbing

Barbing

1 051 km

Dvipusis stiklo šlifavimo staklės

Schiatti AngeloBFP12

Schiatti AngeloBFP12

Mažas skelbimas

Gondelsheim

Gondelsheim

1 239 km

Tilto kranas Salės kranas Krano kilimo ir tūpimo takas Kranas

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Mažas skelbimas

Gościcino

Gościcino

372 km

Stiklo pjaustymo stalas

GlastonUC 1000

GlastonUC 1000

Mažas skelbimas

Krefeld

Krefeld

1 222 km

Teleskopinis konvejeris konvejerio diržo konvejeris

BuddeTGF03

BuddeTGF03

Mažas skelbimas

Maasmechelen

Maasmechelen

1 296 km

Stiklo pjovimo stalas

Bottero548LAM-38 2.0 - 363BCS-J 2.0

Bottero548LAM-38 2.0 - 363BCS-J 2.0

Mažas skelbimas

Zevenbergen

Zevenbergen

1 332 km

CNC tekinimo staklės su Y ašimi, varomos. WK

Mori SeikiNL 2500 SY / 1250

Mori SeikiNL 2500 SY / 1250

Mažas skelbimas

Maasmechelen

Maasmechelen

1 296 km

Stiklo pjaustymo stalas

Bottero353BKM-J

Bottero353BKM-J

Mažas skelbimas

Sliven

Sliven

1 401 km

Skersinių linijų optimizavimas

WEINIGOpticut 200 Elite

WEINIGOpticut 200 Elite

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida