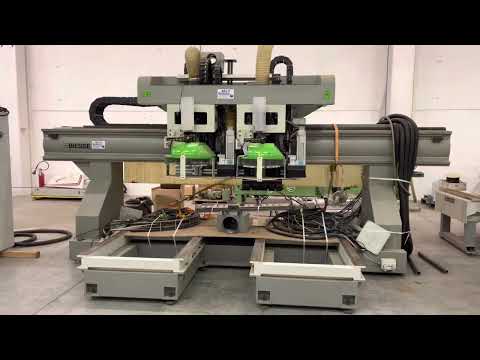

CNC elektroninis pantografasBIESSE

Arrow FT OSAI

CNC elektroninis pantografas

BIESSE

Arrow FT OSAI

Gamybos metai

2004

Sąlyga

Naudotas

Vieta

Cordignano

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- CNC elektroninis pantografas

- Gamintojas:

- BIESSE

- Modelis:

- Arrow FT OSAI

- Gamybos metai:

- 2004

- Sąlyga:

- nepatikrintas (naudotas)

Kaina ir vieta

- Vieta:

- Via Strada Maestra D'Italia, 31016 Cordignano TV, Italia

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A6859336

- Naujinta paskutinį kartą:

- Data 2024.12.29

Aprašymas

Working Area and Axis Travel

No. 2 worktables each measuring 1,600 x 1,800 mm

Total working area with joined tables: 3,220 x 1,800 mm

Axis travel: X = 4,300 mm; Y/W = 3,200 mm; Z = 300 mm

Z workpiece clearance: 300 mm

Vacuum Pumps: Rotating Becker type, No. 2 x 250 m³/h

Mechanical structure: Monolithic steel gantry frame with fixed portal, including base, lateral beams, and upper beam, all thermally welded into a single piece and then thermally stabilized.

The large-section upper beam, 400 x 400 mm, is constructed with a combined section geometry for extremely high rigidity.

Prjdpfxshvmwks Afwsd

Numerical control: Osai with DUAL TFT MONITOR

Industrial Digital OSAI Series 10/510 CNC with integrated second computer:

- WINLINK with TeleService

- Industrial PC integrated into OSAI control

Interactive operator panel

- Dedicated color TFT monitor for OSAI CNC

- Dedicated color TFT monitor for Windows PC

No. 02 Electrospindles:

HSD milling routers, bidirectional (CW/CCW)

Max speed: 32,000 rpm

ISO 30 Special high-speed tool holders

Power:

- 10.5 kW = 14.5 HP at 18,000 rpm

- 10.5 kW = 14.5 HP at 24,000 rpm

- 7.0 kW = 9.5 HP at 32,000 rpm

Front ceramic bearings

Rear ceramic bearings

Coolant-based liquid cooling

Multi-position step-type suction hood, CNC-controlled

Electrospindle floating device

Digital electronic inverter

No. 01 Setting Axis (patented system)

Features an additional independent Z-axis for the operator head no. 2 (left side).

Allows CNC adjustment for Z-axis differences between tool lengths, ensuring all tools working on the same piece are compensated.

Enables operations requiring mechanical copying of the workpiece in floating mode.

No. 02 Rotary arm type tool magazines, each with 10 positions, for rapid and high-performance tool changes

No. 02 HSD Boring Heads:

Type BH 19 each fitted with 19 tool holders:

- 13 independent vertical spindles in a T-configuration:

- 5 along X-axis, 32 mm pitch

- 8 along Y-axis, 32 mm pitch

- 4 horizontal spindles in Y-direction (2+2 opposing)

- 2 horizontal spindles in X-direction (1+1 opposing)

Installation Data:

Footprint approx. 6,950 x 6,700 mm (width x depth)

Power supply: 380 V 3-phase at 50 Hz; I = 100 A; P = 59 kW

Pneumatic supply: 7.00–7.50 Bar

Extraction system: 2 x diameter 200 mm; 30 m/s; at approx. H = 3,200 mm

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

No. 2 worktables each measuring 1,600 x 1,800 mm

Total working area with joined tables: 3,220 x 1,800 mm

Axis travel: X = 4,300 mm; Y/W = 3,200 mm; Z = 300 mm

Z workpiece clearance: 300 mm

Vacuum Pumps: Rotating Becker type, No. 2 x 250 m³/h

Mechanical structure: Monolithic steel gantry frame with fixed portal, including base, lateral beams, and upper beam, all thermally welded into a single piece and then thermally stabilized.

The large-section upper beam, 400 x 400 mm, is constructed with a combined section geometry for extremely high rigidity.

Prjdpfxshvmwks Afwsd

Numerical control: Osai with DUAL TFT MONITOR

Industrial Digital OSAI Series 10/510 CNC with integrated second computer:

- WINLINK with TeleService

- Industrial PC integrated into OSAI control

Interactive operator panel

- Dedicated color TFT monitor for OSAI CNC

- Dedicated color TFT monitor for Windows PC

No. 02 Electrospindles:

HSD milling routers, bidirectional (CW/CCW)

Max speed: 32,000 rpm

ISO 30 Special high-speed tool holders

Power:

- 10.5 kW = 14.5 HP at 18,000 rpm

- 10.5 kW = 14.5 HP at 24,000 rpm

- 7.0 kW = 9.5 HP at 32,000 rpm

Front ceramic bearings

Rear ceramic bearings

Coolant-based liquid cooling

Multi-position step-type suction hood, CNC-controlled

Electrospindle floating device

Digital electronic inverter

No. 01 Setting Axis (patented system)

Features an additional independent Z-axis for the operator head no. 2 (left side).

Allows CNC adjustment for Z-axis differences between tool lengths, ensuring all tools working on the same piece are compensated.

Enables operations requiring mechanical copying of the workpiece in floating mode.

No. 02 Rotary arm type tool magazines, each with 10 positions, for rapid and high-performance tool changes

No. 02 HSD Boring Heads:

Type BH 19 each fitted with 19 tool holders:

- 13 independent vertical spindles in a T-configuration:

- 5 along X-axis, 32 mm pitch

- 8 along Y-axis, 32 mm pitch

- 4 horizontal spindles in Y-direction (2+2 opposing)

- 2 horizontal spindles in X-direction (1+1 opposing)

Installation Data:

Footprint approx. 6,950 x 6,700 mm (width x depth)

Power supply: 380 V 3-phase at 50 Hz; I = 100 A; P = 59 kW

Pneumatic supply: 7.00–7.50 Bar

Extraction system: 2 x diameter 200 mm; 30 m/s; at approx. H = 3,200 mm

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Dokumentai

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2019

Pateikti užklausą

Telefonas & Faksas

+39 335 8... skelbimai

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida