Vertikalus apdirbimo centrasStarrag

HEC 400 F

Vertikalus apdirbimo centras

Starrag

HEC 400 F

Pradinė kaina neįskaitant PVM

135 000 €

Gamybos metai

2016

Sąlyga

Naudotas

Vieta

Warstein

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Vertikalus apdirbimo centras

- Gamintojas:

- Starrag

- Modelis:

- HEC 400 F

- Gamybos metai:

- 2016

- Sąlyga:

- geras (naudotas)

- Funkcionalumas:

- visiškai funkcionalus

- Darbo valandos:

- 27 412 h

Kaina ir vieta

Pradinė kaina neįskaitant PVM

135 000 €

- Vieta:

- Warstein, Vokietija

Skambinti

Techniniai duomenys

- X ašies eiga:

- 650 mm

- Y ašies eiga:

- 650 mm

- Z ašies eigos atstumas:

- 680 mm

- Valdiklių gamintojas:

- Siemens

- Valdiklio modelis:

- 840D sl

- Stalo plotis:

- 400 mm

- Stalo aukštis:

- 30 mm

- Stalo ilgis:

- 500 mm

- Stalo apkrova:

- 500 kg

- Veleno greitis (maks.):

- 18 000 aps./min

- Veleno veikimo valandos:

- 9 956 h

- Aušinimo skysčio tiekimas:

- 80 juosta

- Ašies variklio galia:

- 32 400 W

- Įranga:

- dokumentacija / vadovas, drožlių transporteris, sūkių greitis be galo kintamas

Pasiūlymo informacija

- Sąrašo ID:

- A20768872

- Naujinta paskutinį kartą:

- Data 2026.01.20

Aprašymas

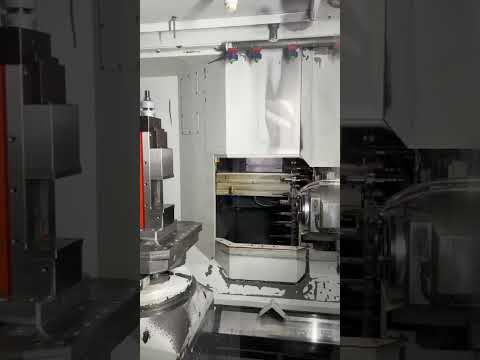

For sale is a Starrag HEC 400 F 4-axis machining center, which was fully inspected and overhauled at the Starrag plant in 2022. During this process, all relevant components were checked and adjusted or replaced as necessary. Since its installation in 2022, the machine has been in operation at our facility and is currently powered on, running out the end of its production cycle. It is in well-maintained technical condition and has been serviced regularly.

Technical Highlights

- Starrag HEC 400 F – 17211, 4-axis machining center for milling / drilling / turning

- Control: Siemens Sinumerik 840 D solution Line with NCU710 and PLC integration

- Spindle: HSK-A63 motor spindle, speed range 50 – 18,000 rpm, torque 130 Nm (25% duty cycle), power 32.4 kW / 24 kW (100% duty cycle)

- Factory inspection in 2022 in Chemnitz: all assemblies checked, adjusted, and renewed as required

- Direct drive NC rotary table, 80 rpm, 400 Nm drive torque, 3,000 Nm tangential moment

- Siemens spindle diagnostics & remote diagnostics (Teamviewer)

- Energy-efficient system with regenerative feedback and standby mode for energy savings

Working Area & Dimensions

- Travels (X/Y/Z): 650 / 650 / 680 mm

- Pallet size: 400 × 500 mm with 57 × M12 threads

- Max. workpiece height: 850 mm • Max. load per pallet: 500 kg

- Pallet changer: 2 pallets – automatic, change time approx. 8 s

- Tool magazine: 60 tool stations (chain magazine) • chip-to-chip time 3 – 4 s

- Chip conveyor: scraper belt conveyor with vacuum gap screen, discharge height 1,050 mm

- Machine dimensions (L × W × H): approx. 5,150 × 2,800 × 3,025 mm

- Machine weight: approx. 11,500 kg

- Noise emission: ≤ 80 dB(A) according to EN ISO 3744

Additional Equipment

- Clamping hydraulics, 6-channel (90 bar) at setup and work station

- Increased spindle torque (130 Nm) for high-performance machining

- Torque support with axial supports

- Coolant system: connection to central supply incl. return and temperature compensation

- Increased coolant pressure to 80 bar through spindle center

- Optical probe Renishaw OMP60 incl. Siemens measurement cycles

- Tool breakage detection (mechanical, parallel to main time)

- Pallet sequence operation + crane loading/unloading (software)

- Signaling light (4-color) for operating states

- Work area / machine equipment: shower, blow gun, vortex nozzle, extraction interface, foot switch blow nozzle

- Documentation: fully digital (PDF)

Operating Hours / Running Times

- Power-on time approx. 27,412 h (as of Oct 2025)

The counter runs as soon as the machine is turned on – including during setup, maintenance, or downtime.

- Spindle operating time: 9,956 h total

Special Features

- OPTIONAL: Perfect postprocessor and CAM software TOP Solid (available at extra cost)

- Powered on – demonstration possible at any time

- Direct from production – not a dealer sale

- Complete technical documentation available

- Support with dismantling, loading, and transport possible (at extra cost)

The tool holders and vise visible in the photos are not included in the offer but can be purchased separately on request.

Price €135,000 net, negotiable for quick transaction.

All information has been compiled to the best of our knowledge and belief. Subject to change, errors, and prior sale.

Bcjdpex H Idkofx Abfju

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Technical Highlights

- Starrag HEC 400 F – 17211, 4-axis machining center for milling / drilling / turning

- Control: Siemens Sinumerik 840 D solution Line with NCU710 and PLC integration

- Spindle: HSK-A63 motor spindle, speed range 50 – 18,000 rpm, torque 130 Nm (25% duty cycle), power 32.4 kW / 24 kW (100% duty cycle)

- Factory inspection in 2022 in Chemnitz: all assemblies checked, adjusted, and renewed as required

- Direct drive NC rotary table, 80 rpm, 400 Nm drive torque, 3,000 Nm tangential moment

- Siemens spindle diagnostics & remote diagnostics (Teamviewer)

- Energy-efficient system with regenerative feedback and standby mode for energy savings

Working Area & Dimensions

- Travels (X/Y/Z): 650 / 650 / 680 mm

- Pallet size: 400 × 500 mm with 57 × M12 threads

- Max. workpiece height: 850 mm • Max. load per pallet: 500 kg

- Pallet changer: 2 pallets – automatic, change time approx. 8 s

- Tool magazine: 60 tool stations (chain magazine) • chip-to-chip time 3 – 4 s

- Chip conveyor: scraper belt conveyor with vacuum gap screen, discharge height 1,050 mm

- Machine dimensions (L × W × H): approx. 5,150 × 2,800 × 3,025 mm

- Machine weight: approx. 11,500 kg

- Noise emission: ≤ 80 dB(A) according to EN ISO 3744

Additional Equipment

- Clamping hydraulics, 6-channel (90 bar) at setup and work station

- Increased spindle torque (130 Nm) for high-performance machining

- Torque support with axial supports

- Coolant system: connection to central supply incl. return and temperature compensation

- Increased coolant pressure to 80 bar through spindle center

- Optical probe Renishaw OMP60 incl. Siemens measurement cycles

- Tool breakage detection (mechanical, parallel to main time)

- Pallet sequence operation + crane loading/unloading (software)

- Signaling light (4-color) for operating states

- Work area / machine equipment: shower, blow gun, vortex nozzle, extraction interface, foot switch blow nozzle

- Documentation: fully digital (PDF)

Operating Hours / Running Times

- Power-on time approx. 27,412 h (as of Oct 2025)

The counter runs as soon as the machine is turned on – including during setup, maintenance, or downtime.

- Spindle operating time: 9,956 h total

Special Features

- OPTIONAL: Perfect postprocessor and CAM software TOP Solid (available at extra cost)

- Powered on – demonstration possible at any time

- Direct from production – not a dealer sale

- Complete technical documentation available

- Support with dismantling, loading, and transport possible (at extra cost)

The tool holders and vise visible in the photos are not included in the offer but can be purchased separately on request.

Price €135,000 net, negotiable for quick transaction.

All information has been compiled to the best of our knowledge and belief. Subject to change, errors, and prior sale.

Bcjdpex H Idkofx Abfju

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Pateikti užklausą

Telefonas & Faksas

+49 2902 ... skelbimai

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida