Lazerinio pjaustymo staklėsPFEIFER technology

skyCUBE CO2 Laser / Faser Laser

Lazerinio pjaustymo staklės

PFEIFER technology

skyCUBE CO2 Laser / Faser Laser

Gamybos metai

2025

Sąlyga

Naujas

Vieta

Plauen

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Lazerinio pjaustymo staklės

- Gamintojas:

- PFEIFER technology

- Modelis:

- skyCUBE CO2 Laser / Faser Laser

- Gamybos metai:

- 2025

- Sąlyga:

- naujas

Kaina ir vieta

- Vieta:

- Rathenaupl. 78, 08525 Plauen, Deutschland

Skambinti

Pasiūlymo informacija

- Sąrašo ID:

- A1421521

- Nuorodos Nr.:

- SKYCUBE M-P-SL

- Naujinta paskutinį kartą:

- Data 2025.02.04

Aprašymas

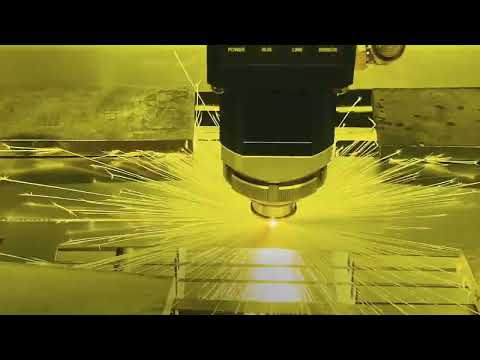

The skyCUBE M / P / SL laser processing center – the new benchmark in laser materials processing!

(* Price depends on configuration; this is a brand new laser machine manufactured by us)

Laser options to suit your needs: CO2 laser 150W / 250W / 400W or fiber laser 1500 – 6000W

PFEIFER Laser Processing Center skyCUBE

Lhodobnphvepfx Af Iob

Working areas:

Mclass = X 1250 x Y 650 x Z 100 mm

Pclass = X 1250 x Y 1250 x Z 100 mm

SLclass = X 1250 x Y 2550 x Z 100 mm

skyCUBE laser processing center – the new multifunctional laser engraving and cutting machine – laser processing made easy – highly precise – laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent impresses even the most experienced users, not only with its newly thought-out design. This CO2 laser / fiber laser demonstrates outstanding capabilities in all industrial applications, both as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser. With an optional laser output of up to 1500W (1.5kW), the CO2 laser device / fiber laser system is also extremely flexible to use in your production.

skyCUBE laser devices meet all Class 1 requirements in accordance with DIN EN 60825-1, providing you with the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving numerous materials, including various metals, acrylic glass, solid wood & wood composites, engineered wood products, paper, cardboard, various plastics & foams, textiles, and much more.

The outstanding build quality of the laser machine, produced 100% in Plauen, Germany, guarantees users – from metalworking to laser source – high working precision and consistently high quality. With cutting speeds up to 8000 mm/s and engraving speeds up to 4000 mm/s, the high-quality laser technology delivers clean and very sharp cut edges and precise laser engravings.

The ergonomic design with a pull-out worktable makes it easy to load the system. A drawer in the lower part of the machine collects the cut material.

User-friendly and intuitive – the included skyCUBE PC software (ready for Windows®). A simple, practical, and Windows-standard user interface allows you to work quickly and efficiently. High system stability, professional monitoring with appropriate machine operation and control, and compatibility with common file formats characterize the software. Data output is performed in layers – each layer separately, including the definition of sequences and processing type. Parameters such as laser power and processing speed are automatically saved for each layer and can be recalled at any time from a material database. With a computer connected via LAN / USB interface, laser projects are transmitted to the skyCUBE M laser processing center. From there, they can be executed repeatedly without the PC needing to remain switched on.

A modern touch control panel gives you access to all system information and functions.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

(* Price depends on configuration; this is a brand new laser machine manufactured by us)

Laser options to suit your needs: CO2 laser 150W / 250W / 400W or fiber laser 1500 – 6000W

PFEIFER Laser Processing Center skyCUBE

Lhodobnphvepfx Af Iob

Working areas:

Mclass = X 1250 x Y 650 x Z 100 mm

Pclass = X 1250 x Y 1250 x Z 100 mm

SLclass = X 1250 x Y 2550 x Z 100 mm

skyCUBE laser processing center – the new multifunctional laser engraving and cutting machine – laser processing made easy – highly precise – laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent impresses even the most experienced users, not only with its newly thought-out design. This CO2 laser / fiber laser demonstrates outstanding capabilities in all industrial applications, both as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser. With an optional laser output of up to 1500W (1.5kW), the CO2 laser device / fiber laser system is also extremely flexible to use in your production.

skyCUBE laser devices meet all Class 1 requirements in accordance with DIN EN 60825-1, providing you with the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving numerous materials, including various metals, acrylic glass, solid wood & wood composites, engineered wood products, paper, cardboard, various plastics & foams, textiles, and much more.

The outstanding build quality of the laser machine, produced 100% in Plauen, Germany, guarantees users – from metalworking to laser source – high working precision and consistently high quality. With cutting speeds up to 8000 mm/s and engraving speeds up to 4000 mm/s, the high-quality laser technology delivers clean and very sharp cut edges and precise laser engravings.

The ergonomic design with a pull-out worktable makes it easy to load the system. A drawer in the lower part of the machine collects the cut material.

User-friendly and intuitive – the included skyCUBE PC software (ready for Windows®). A simple, practical, and Windows-standard user interface allows you to work quickly and efficiently. High system stability, professional monitoring with appropriate machine operation and control, and compatibility with common file formats characterize the software. Data output is performed in layers – each layer separately, including the definition of sequences and processing type. Parameters such as laser power and processing speed are automatically saved for each layer and can be recalled at any time from a material database. With a computer connected via LAN / USB interface, laser projects are transmitted to the skyCUBE M laser processing center. From there, they can be executed repeatedly without the PC needing to remain switched on.

A modern touch control panel gives you access to all system information and functions.

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2011

Pateikti užklausą

Telefonas & Faksas

+49 3741 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Ahaus

Ahaus

1 162 km

Stulpo strėlės kranas

ABUSLS / 4000 MM x 500 KG

ABUSLS / 4000 MM x 500 KG

Mažas skelbimas

Ciriè

Ciriè

1 596 km

APDIRBIMO CENTRAS

ParpasXS63

ParpasXS63

Mažas skelbimas

Poznań

Poznań

556 km

Garo generatorius

WIMA

WIMA

Mažas skelbimas

Lyon

Lyon

1 699 km

Ø2,0 mm/2 ašių suspaudimo spyruoklių staklės

JD220

JD220

Mažas skelbimas

Scerne

Scerne

1 566 km

Mobilus angaras

CoprikompattCTDZ

CoprikompattCTDZ

Mažas skelbimas

Thurmaston

Thurmaston

1 651 km

CNC tekinimo ir frezavimo centras

DOOSANPuma 2600SY

DOOSANPuma 2600SY

Mažas skelbimas

Seesen

Seesen

978 km

Tentinė furgonė

MERCEDES-BENZSprinter 316 Schiebeplane 420 x 220 x 220 cm

MERCEDES-BENZSprinter 316 Schiebeplane 420 x 220 x 220 cm

Mažas skelbimas

Leipzig

Leipzig

874 km

Lazerinio pjaustymo staklės

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

Mažas skelbimas

Włoszczowa

Włoszczowa

548 km

CNC reguliuojamoms durų staktoms

ESSEPIGIHORIZON EST

ESSEPIGIHORIZON EST

Mažas skelbimas

Gusselby

Gusselby

718 km

Rąstų vežimo konvejeris

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida