Liepsnos pjovimo sistemaPFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Liepsnos pjovimo sistema

PFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Gamybos metai

2026

Sąlyga

Naujas

Vieta

Plauen

Rodyti vaizdus

Rodyti žemėlapį

Duomenys apie mašiną

- Įrenginio aprašas:

- Liepsnos pjovimo sistema

- Gamintojas:

- PFEIFER technology & innovation Plauen D

- Gamybos metai:

- 2026

- Sąlyga:

- naujas

- Funkcionalumas:

- visiškai funkcionalus

Kaina ir vieta

- Vieta:

- Rathenaupl. 8, 08525 Plauen, Deutschland

Skambinti

Techniniai duomenys

- Darbo diapazonas:

- 6 500 mm

- Įvesties srovės tipas:

- trifazis

- Bendras plotis:

- 1 629 mm

- Bendras aukštis:

- 2 525 mm

- Bendras ilgis:

- 10 500 mm

- Stalo ilgis:

- 6 500 mm

- Bendras svoris:

- 5 500 kg

- Galia:

- 15 kW (20,39 AG)

- Lazerio galia:

- 6 000 W

- Garantijos trukmė:

- 24 mėnesiai

- Įranga:

- apsaugos šviesos užtvara, aušinimo blokas

Pasiūlymo informacija

- Sąrašo ID:

- A14903902

- Nuorodos Nr.:

- skyTUBE6500 FIBER

- Naujinta paskutinį kartą:

- Data 2026.02.09

Aprašymas

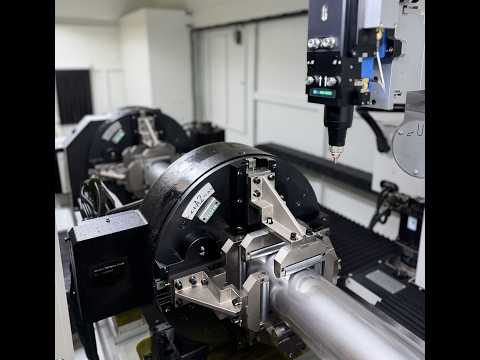

PFEIFER technology skyTUBE Pro 6500 X3 – Profile & Tube Laser Center 6500 x 15 – 160 mm Format

The skytube-pro-6500×3 profile and tube laser, a fiber laser metal cutting system optimized for fast material changes with up to 6kW of power, offers a smart and efficient tube laser processing solution for your production needs. It is ideal for laser cutting round tubes, square tubes, rectangular tubes, open sections, and special profiles—a laser machine designed for maximum productivity during production changeovers. The requirement: fiber laser up to 6kW for various metal processing tasks!

Unmatched Laser Cutting Performance

High axis speeds and accelerations, combined with a robust mechanical structure, enable excellent cutting performance and accuracy.

Hodpjrh Iw Tsfx Agioi

The tube and profile laser processing machine is compact for production environments—simply clever! Ingenious solutions, 100% from Saxony!

Tubes and profiles from 15 x 15 up to 160 x 160 mm, 3D cutting with efficient fiber laser technology.

The semi-automatic 6-position profile tube chain loading system enables rapid job changes. With the optional bundle loader, you can operate independently.

Bevel Cutting

A feature that changes everything. Thanks to our machines’ capability to swivel the cutting head by up to 50° on an additional fifth axis, one of the major challenges in modern profile processing has been overcome. If the laser beam always hits the workpiece perpendicular, it results in an elliptical cut edge. With the ability to tilt the tube laser cutting head, a perfectly angled cut can now be achieved together with the feed axis.

Naturally, you are always on the safe side with the skyTUBE laser!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser radiation or reflections during operation. For all our laser systems, complete safety and compliance with the highest standards and regulations are our top priority.

Technical Specifications:

· Enclosed industrial housing, Class 1 laser (or Class 4 upon request)

· Working area for tube cutting / clamping system: round tubes 15–160 mm, rectangular tubes 15 x 15–110 mm

· Working area on tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

· Automatic material feed for up to 6 x 160 mm profiles, 3500–7000 mm in length

· Automatic unloading system for profiles, custom-designed by profile length

· Z drive system: Ball screw axis / with PTI SVZ system

· X/Y drive system: Linear axis / with PTI AC-SERVO system

· Productive cutting speed: up to 50 m/min (1.4G), depending on material and laser configuration

· Software resolution: up to 2500 DPI

· Repeatability: ±0.03 mm

· Maximum footprint (WxDxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system, depending on profile cut length

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

The skytube-pro-6500×3 profile and tube laser, a fiber laser metal cutting system optimized for fast material changes with up to 6kW of power, offers a smart and efficient tube laser processing solution for your production needs. It is ideal for laser cutting round tubes, square tubes, rectangular tubes, open sections, and special profiles—a laser machine designed for maximum productivity during production changeovers. The requirement: fiber laser up to 6kW for various metal processing tasks!

Unmatched Laser Cutting Performance

High axis speeds and accelerations, combined with a robust mechanical structure, enable excellent cutting performance and accuracy.

Hodpjrh Iw Tsfx Agioi

The tube and profile laser processing machine is compact for production environments—simply clever! Ingenious solutions, 100% from Saxony!

Tubes and profiles from 15 x 15 up to 160 x 160 mm, 3D cutting with efficient fiber laser technology.

The semi-automatic 6-position profile tube chain loading system enables rapid job changes. With the optional bundle loader, you can operate independently.

Bevel Cutting

A feature that changes everything. Thanks to our machines’ capability to swivel the cutting head by up to 50° on an additional fifth axis, one of the major challenges in modern profile processing has been overcome. If the laser beam always hits the workpiece perpendicular, it results in an elliptical cut edge. With the ability to tilt the tube laser cutting head, a perfectly angled cut can now be achieved together with the feed axis.

Naturally, you are always on the safe side with the skyTUBE laser!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser radiation or reflections during operation. For all our laser systems, complete safety and compliance with the highest standards and regulations are our top priority.

Technical Specifications:

· Enclosed industrial housing, Class 1 laser (or Class 4 upon request)

· Working area for tube cutting / clamping system: round tubes 15–160 mm, rectangular tubes 15 x 15–110 mm

· Working area on tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

· Automatic material feed for up to 6 x 160 mm profiles, 3500–7000 mm in length

· Automatic unloading system for profiles, custom-designed by profile length

· Z drive system: Ball screw axis / with PTI SVZ system

· X/Y drive system: Linear axis / with PTI AC-SERVO system

· Productive cutting speed: up to 50 m/min (1.4G), depending on material and laser configuration

· Software resolution: up to 2500 DPI

· Repeatability: ±0.03 mm

· Maximum footprint (WxDxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system, depending on profile cut length

Skelbimas verčiamas automatiškai, todėl jame gali būtų vertimo klaidų.

Dokumentai

Tiekėjas

Pastaba: Užsiregistruokite nemokamai arba prisijunkite, kad gautumėte visą informaciją.

Registruota nuo: 2011

Pateikti užklausą

Telefonas & Faksas

+49 3741 ... skelbimai

Šie skelbimai taip pat gali jus sudominti.

Mažas skelbimas

Plauen

Plauen

944 km

Vamzdžių ir profilių lazerinio pjovimo staklės

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

Mažas skelbimas

Leipzig

Leipzig

874 km

Lazerinio pjaustymo staklės

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

Mažas skelbimas

Grebenau

Grebenau

1 082 km

Perforavimo ir lenkimo staklės

BIHLERRM 35

BIHLERRM 35

Mažas skelbimas

Deinze

Deinze

1 434 km

Vamzdžių lenkimo mašinos

ArloSPB60 CNC

ArloSPB60 CNC

Mažas skelbimas

Loire

Loire

1 872 km

Fiber Laser Tube pjovimo mašina

Bodor T2

Bodor T2

Mažas skelbimas

Saerbeck

Saerbeck

1 118 km

Lazerinio pjaustymo staklės

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Mažas skelbimas

Debrecen

Debrecen

858 km

Lazerio pjovimo staklės

TRUMPFTruLaser Tube 7000 fiber

TRUMPFTruLaser Tube 7000 fiber

Mažas skelbimas

Gondelsheim

Gondelsheim

1 238 km

Kranų stoglangis Kranas portalinis kranas

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Mažas skelbimas

Enschede

Enschede

1 163 km

Vamzdžių lazerinės pjovimo staklės

Bodor K2

Bodor K2

Mažas skelbimas

Ludwigsstadt

Ludwigsstadt

989 km

Šepetėlių šalinimo mašina

WeberTTS-1100

WeberTTS-1100

Jūsų skelbimas sėkmingai pašalintas

Įvyko klaida